A saddle-type large tube seat welding method

A welding method and technology for large pipe bases, which are applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult welding, high labor intensity and low degree of automation, and reduce the difficulty of welding and groove grooves. Processing difficulty, improving stability and reliability, and achieving automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail.

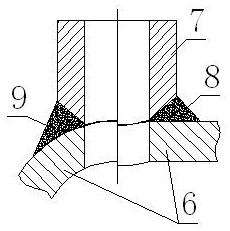

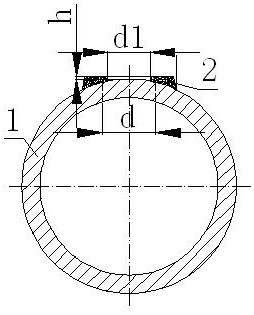

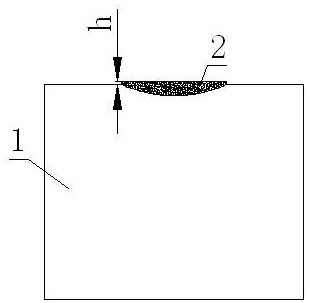

[0019] The welding method of the saddle-type large pipe seat in this embodiment includes the following steps: A) draw the center line of the pipe hole of the pipe seat on the cylinder body, and draw the abdominal surfacing welding filling range line on the cylinder body according to the size of the pipe seat; B) like figure 2 , image 3 As shown, according to the filling range line of the surfacing welding of the abdomen, the distance h between the surfacing metal 2 on the abdomen of the cylinder 1 and the height above the shoulder is not less than 5 mm. The surfacing metal 2 is a round platform with an inner hole. The outer diameter of the top is larger than the outer diameter of the pipe seat, and the inner diameter d1 of the round table is smaller than the inner diameter d of the pipe seat. The surfacing welding adopts automatic identification, automatic tracking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com