Soldering flux matched with lead-free solder

A lead-free solder and flux technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of high melting point, poor wettability, and difficult cleaning, and meet environmental protection requirements. Safe and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

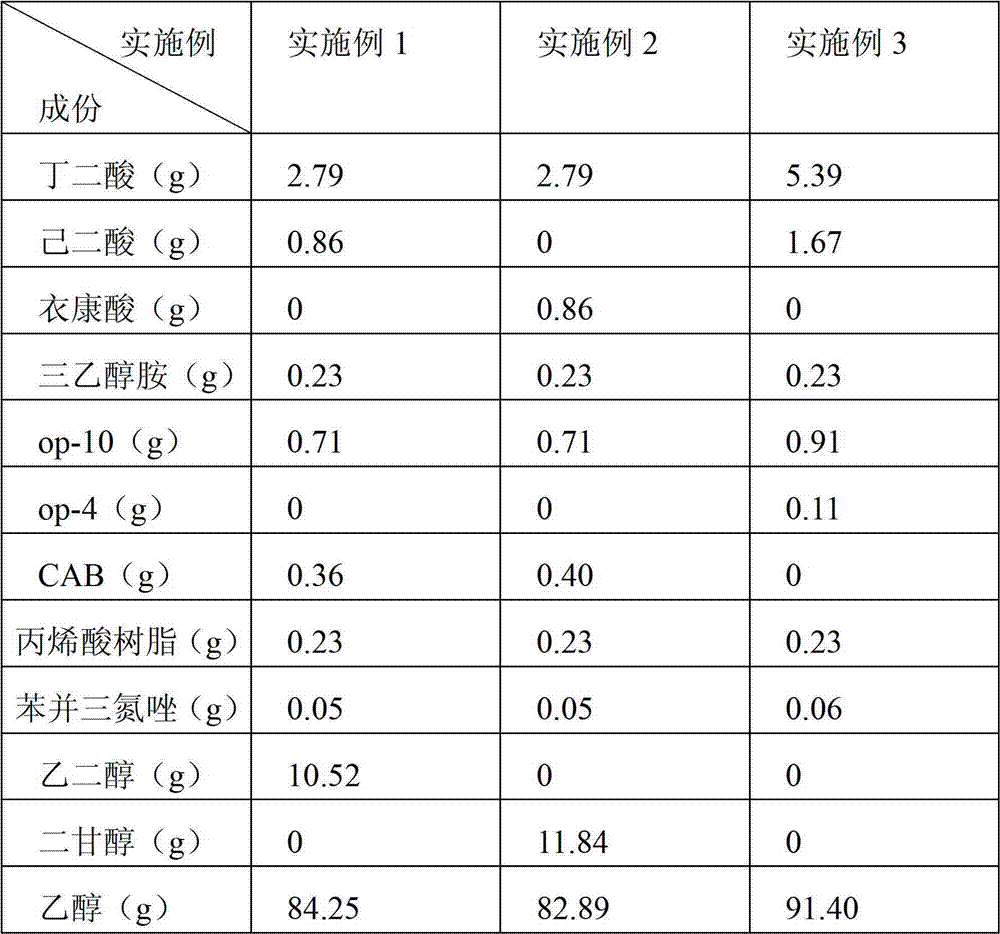

[0032] Weigh 2.79g succinic acid, 0.86g adipic acid, 0.23g triethanolamine, 0.71gop-10, 0.36g CAB, 0.23g acrylic resin, 0.05g benzotriazole and completely dissolve in 10.52g ethylene glycol, 84.25 g ethanol compound solvent.

Embodiment 2

[0034] Weigh 2.79g succinic acid, 0.86g itaconic acid, 0.23g triethanolamine, 0.71gop-10, 0.40g CAB, 0.23g acrylic resin, 0.05g benzotriazole and completely dissolve in 11.84g diethylene glycol, 82.89 g ethanol compound solvent.

Embodiment 3

[0036] Weigh 5.39g of succinic acid, 1.67g of adipic acid, 0.23g of triethanolamine, 0.91gop-10, 0.11g of op-4, 0.23g of acrylic resin, and 0.06g of benzotriazole and dissolve them completely in 91.40g of ethanol solvent.

[0037] Table 1 is the weight percent of the main components of the flux in Examples 1-3.

[0038]

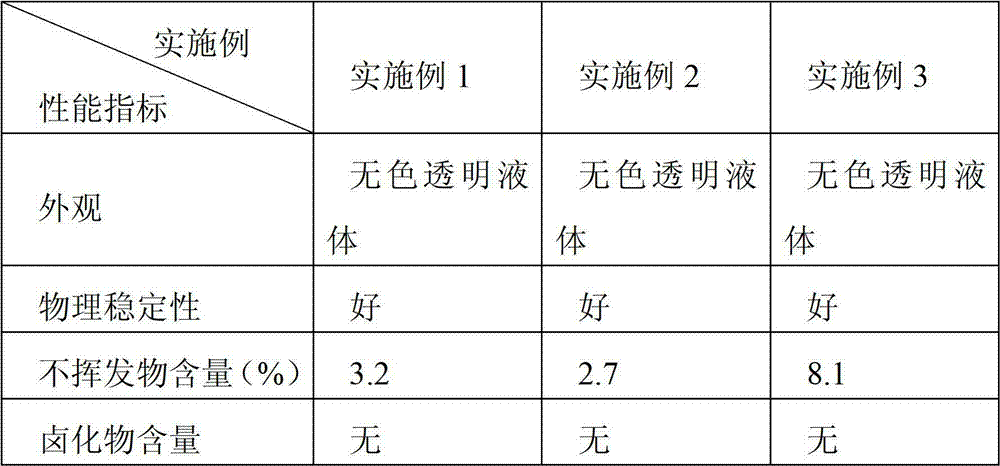

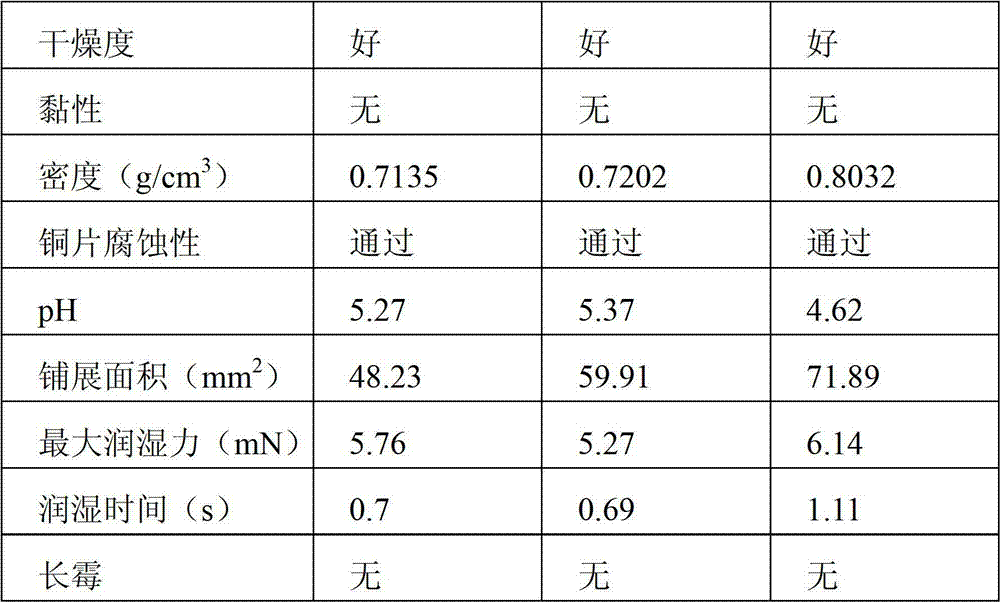

[0039] Table 2 shows the performance evaluation results of the fluxes in Examples 1-3 according to the performance testing standard of "No-Clean Liquid Flux SJ / T 11273-2002".

[0040]

[0041]

[0042] From the performance evaluation results in Table 2, it can be seen that the fluxes in Examples 1-3 all have the advantages of good physical stability, low residual solid content, no halogen, and low corrosion. type flux requirements.

[0043]Adopt the flux described in embodiment 1 and SnAgCu brazing filler metal, implement wave soldering welding process on the PCB board that is inserted with the electronic components and parts with lead wire, the app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com