Intelligent wave soldering tin bath

A wave soldering and tin bath technology, applied in the field of intelligent wave soldering baths, can solve the problems of increased oxygen content, increased oxygen content and impurities, and large volume of wave soldering baths, so as to improve welding quality, save energy, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

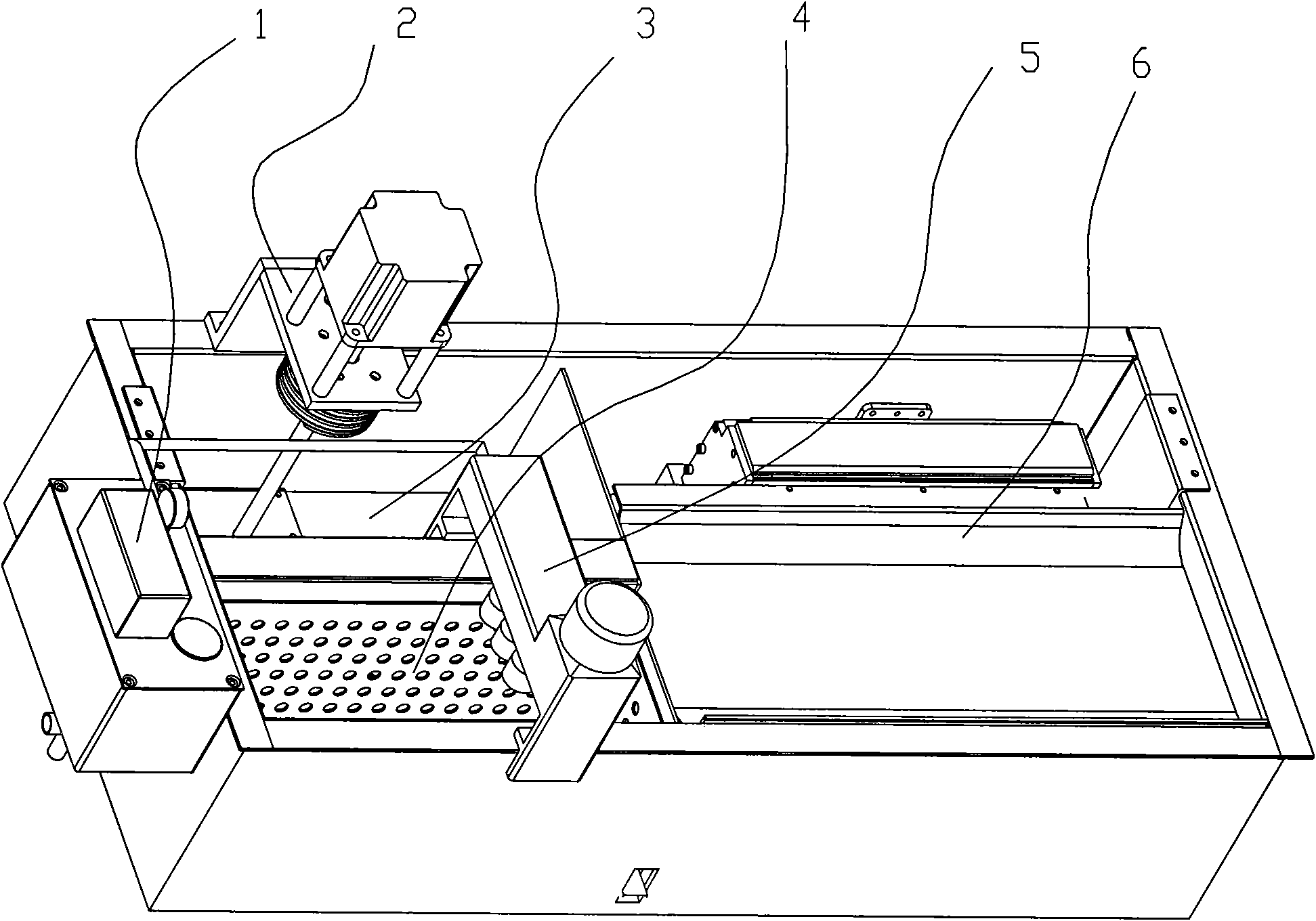

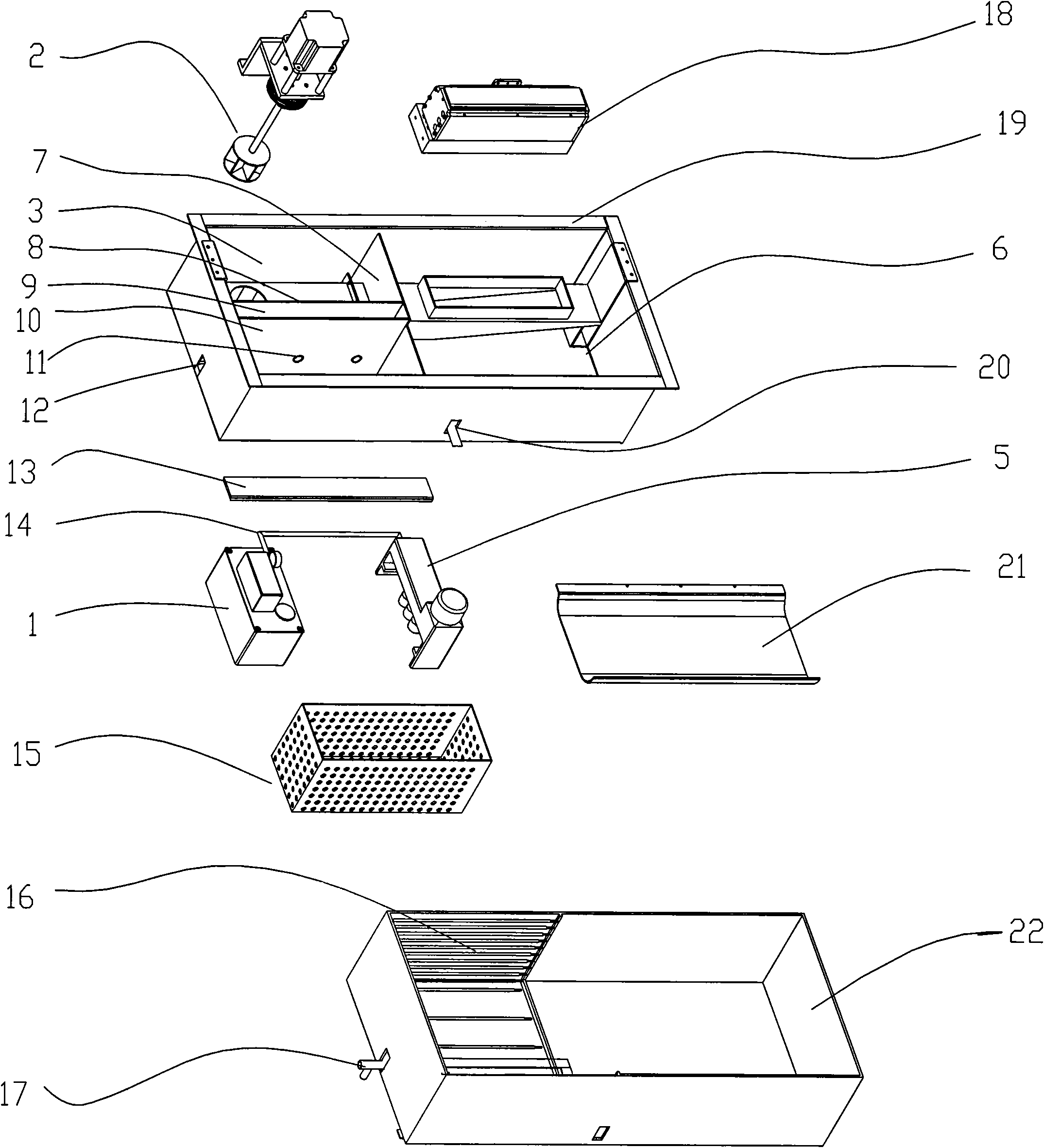

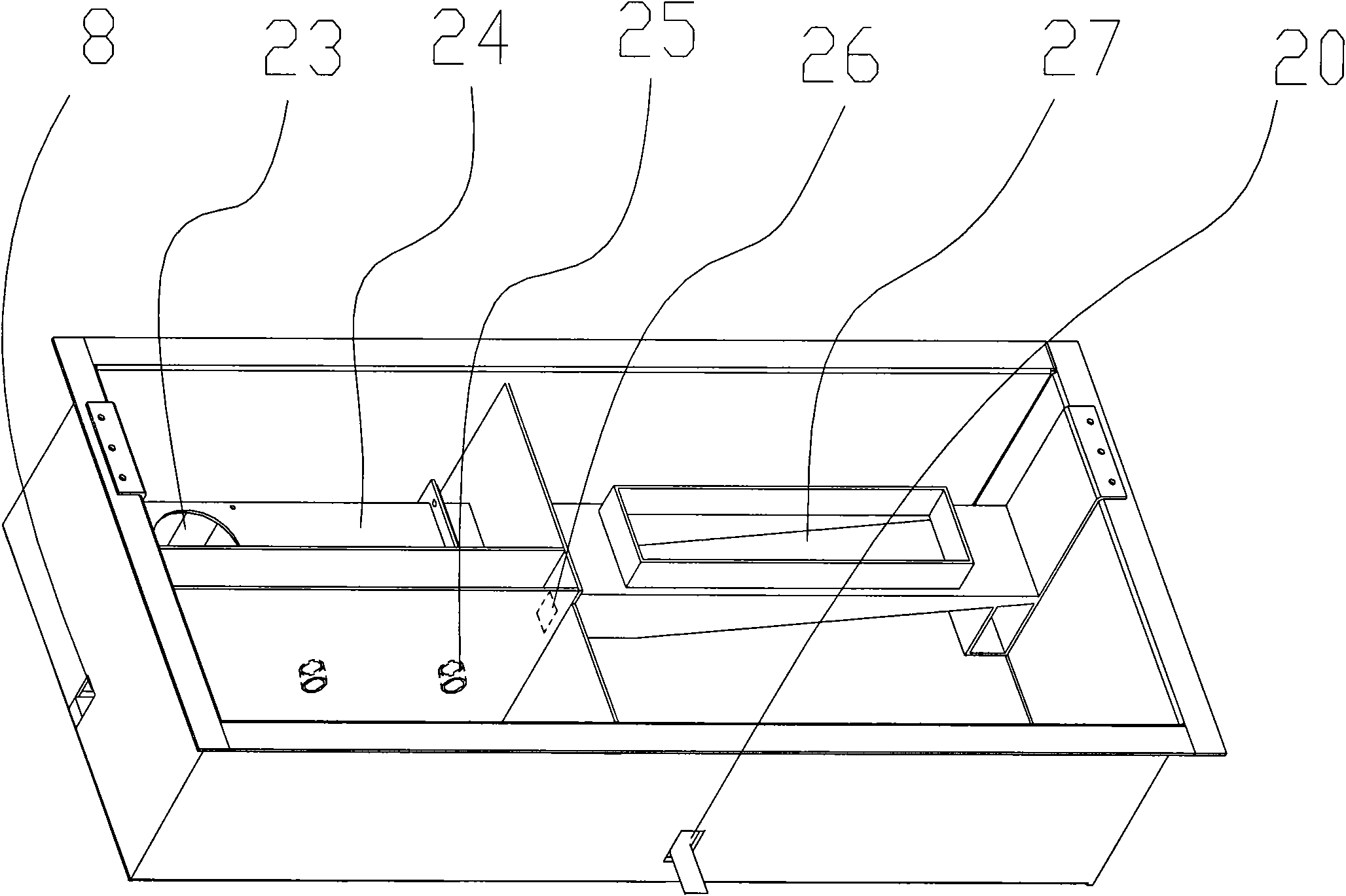

[0012] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0013] An intelligent wave soldering tank includes a tank body 19 and a tank shell 22, the tank body 19 is composed of a transverse partition 7 in the middle and two vertical partitions 8, 10 perpendicular to the transverse partition 7 and the four sides of the tank body 19 Separated into three mutually independent spaces, wherein a space separated by the three sides of the tank body 19 of the transverse diaphragm 7 and the tank body 19 is the air return chamber 6, the longitudinal diaphragm 8, the longitudinal diaphragm 10, the transverse diaphragm 7 and the groove The other two spaces separated by the three sides of the body 19 are the solder chamber 3 and the copper removal chamber 4, and the lower parts of the two longitudinal partitions 8, 10 are provided with two return tin pipes 11 connecting between the solder cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com