Integral forming method for nut board

A forming method and nut plate technology, applied in the field of automobile panel manufacturing, can solve the problems of non-straight walls, damage to the strength and function of the nut, uneven wall thickness, etc., to avoid the problems of virtual riveting and virtual welding, and to achieve high strength and pull-off resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

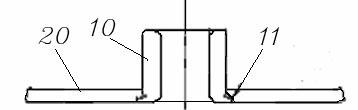

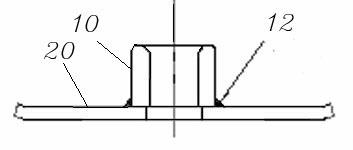

[0022] Such as Figure 4 to combine Figure 5 Shown, a kind of nut plate integral molding method of the present invention, its steps are:

[0023] A. Punch out a ring-shaped flange with a large aperture whose height is equal to the height of the nut at one time on the motherboard;

[0024] B. Keeping the height of the ring flange and the volume of the ring flange constant, the inner diameter and outer diameter of the ring flange are gradually reduced by continuous stamping until the thickness of the ring flange reaches the strength Require;

[0025] C. Finally finish the inner hole of the ring flange and tap to form the nut of the nut plate.

[0026] Through the above method of equal height and diameter reduction, this one-piece nut plate has very significant technological advantages in continuous mold production, and can replace the original welding and riveting scheme, with obvious thickening. CAE calculation analysis is performed on it with Autoform, and the analysis res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com