Method for producing titanium slabs efficiently

A titanium slab, high-efficiency technology, applied in the field of high-efficiency production of titanium slabs, can solve the problems of thick surface oxide layer, complex process, high processing costs, etc., achieve excellent flatness and straightness, uniform chemical composition, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: single ingot smelting

[0039] Raw material: Grade 1 titanium sponge.

[0040] Equipment: EBCHR 6 / 200 / 3600 electron beam cooling hearth furnace.

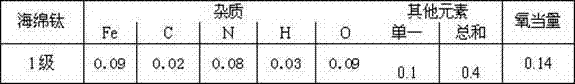

[0041] The chemical composition requirements of sponge titanium are shown in Table 4.

[0042] Table 4

[0043]

[0044] Actual smelting process:

[0045] A. Prepare 30 barrels of titanium sponge that meet the composition requirements, and load it three times, with 10 barrels for each feeding, and put it into the drum feeder of the electron beam cooling bed furnace.

[0046] B. Vacuumize the melting chamber, vibration feeding chamber, drum feeder and ingot drawing chamber of the electron beam cooling bed furnace to 4x 10-2Pa, then open the plate valve of the ingot drawing chamber, and lift the bottom pad of the ingot into the water-cooled copper crucible middle.

[0047] C. Open the plate valve of the vibrating feeding chamber, open the feed port of the vibrating feeder above the melting cooling bed, and...

Embodiment 2

[0066] Example 2: Twin ingot melting

[0067] Raw material: Grade 0 titanium sponge.

[0068] Equipment: EBCHR 6 / 200 / 3600 electron beam cooling hearth furnace.

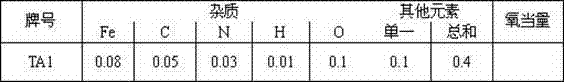

[0069] The chemical composition requirements of sponge titanium are shown in Table 6.

[0070] Table 6

[0071]

[0072] Actual smelting process:

[0073] A. Prepare 60 barrels of sponge titanium that meet the composition requirements, and load it in six times, with 10 barrels for each feeding, and put it into the drum feeder of the electron beam cooling bed furnace.

[0074] B. Vacuumize the melting chamber, vibration feeding chamber, drum feeder and ingot drawing chamber of the electron beam cooling bed furnace to 4x 10-2Pa, then open the plate valve of the ingot drawing chamber, and lift the bottom pad of the ingot into the water-cooled copper crucible middle.

[0075] C. Open the plate valve of the vibrating feeding chamber, open the feed port of the vibrating feeder above the melting cooling bed, and the...

Embodiment 3

[0093] Embodiment 3: single ingot smelting

[0094] Raw material: block TA1 recycled material.

[0095] Equipment: EBCHR 6 / 200 / 3600 electron beam cooling hearth furnace.

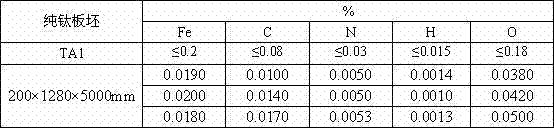

[0096] The chemical composition requirements of recycled materials are shown in Table 8.

[0097] Table 8

[0098]

[0099] Actual smelting process:

[0100] A. After blasting and pickling the TA1 recycled material, put it into a 450x450x1600mm titanium rod box and put it into the rod feeder of the electron beam cooling bed furnace.

[0101] B. Vacuumize the melting chamber, rod feeding chamber and ingot drawing chamber of the electron beam cooling bed furnace to 4x 10-2Pa, then open the plate valve of the ingot drawing chamber, and raise the bottom pad of the ingot drawing into the water-cooled copper crucible.

[0102] C. Turn on the 1#, 2#, 3#, 4#, 5# electron guns, select the "electron beam positioning" step, and confirm the working status of each electron gun and the clarity and angle of the strobe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com