Composite pipe lining, method and apparatus for installing composite lining

A technology of composite lining and pipeline, applied in the direction of mechanical equipment, hoses, pipes, etc., can solve the problems of difficult and expensive lining of large-diameter pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

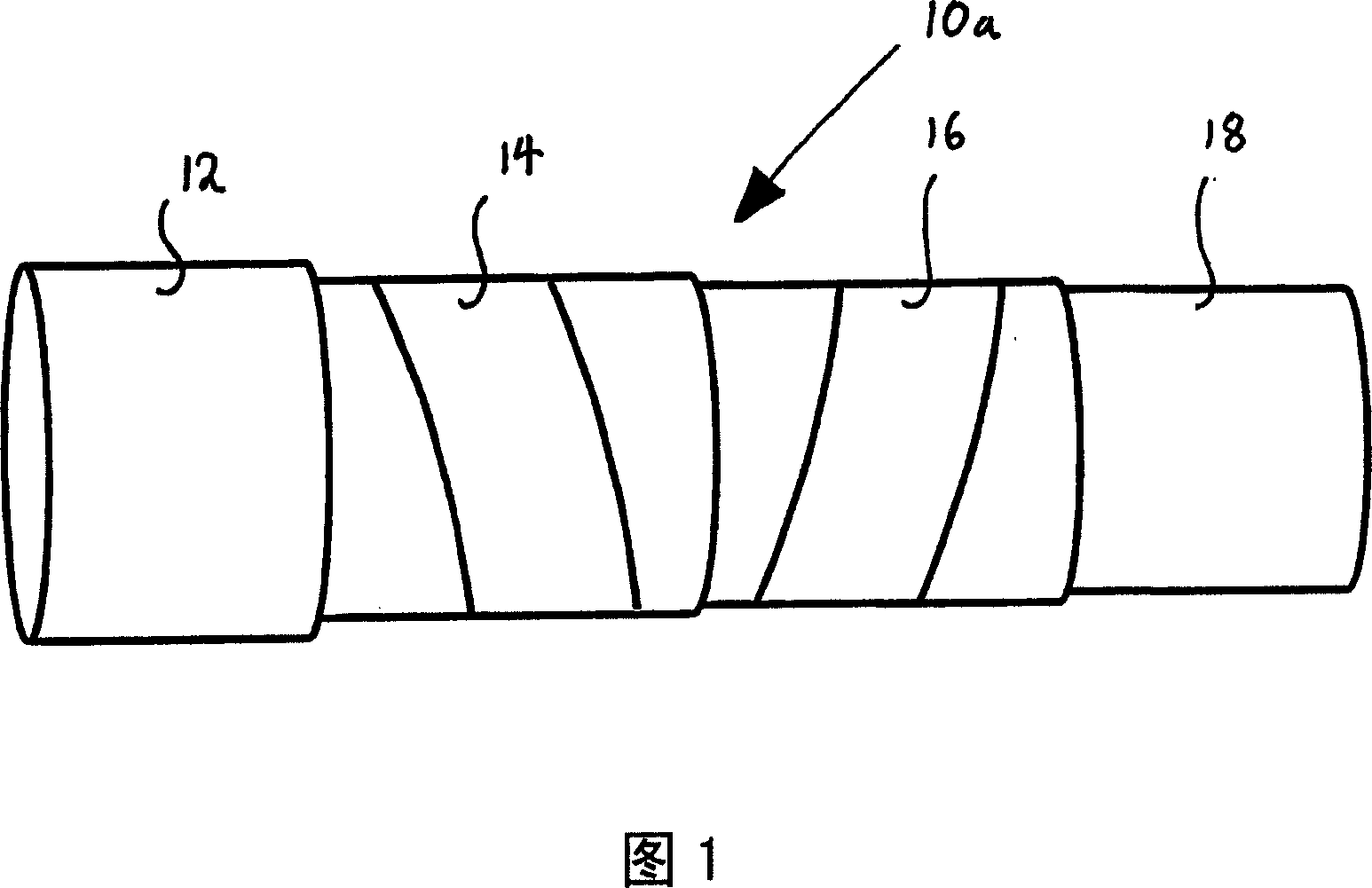

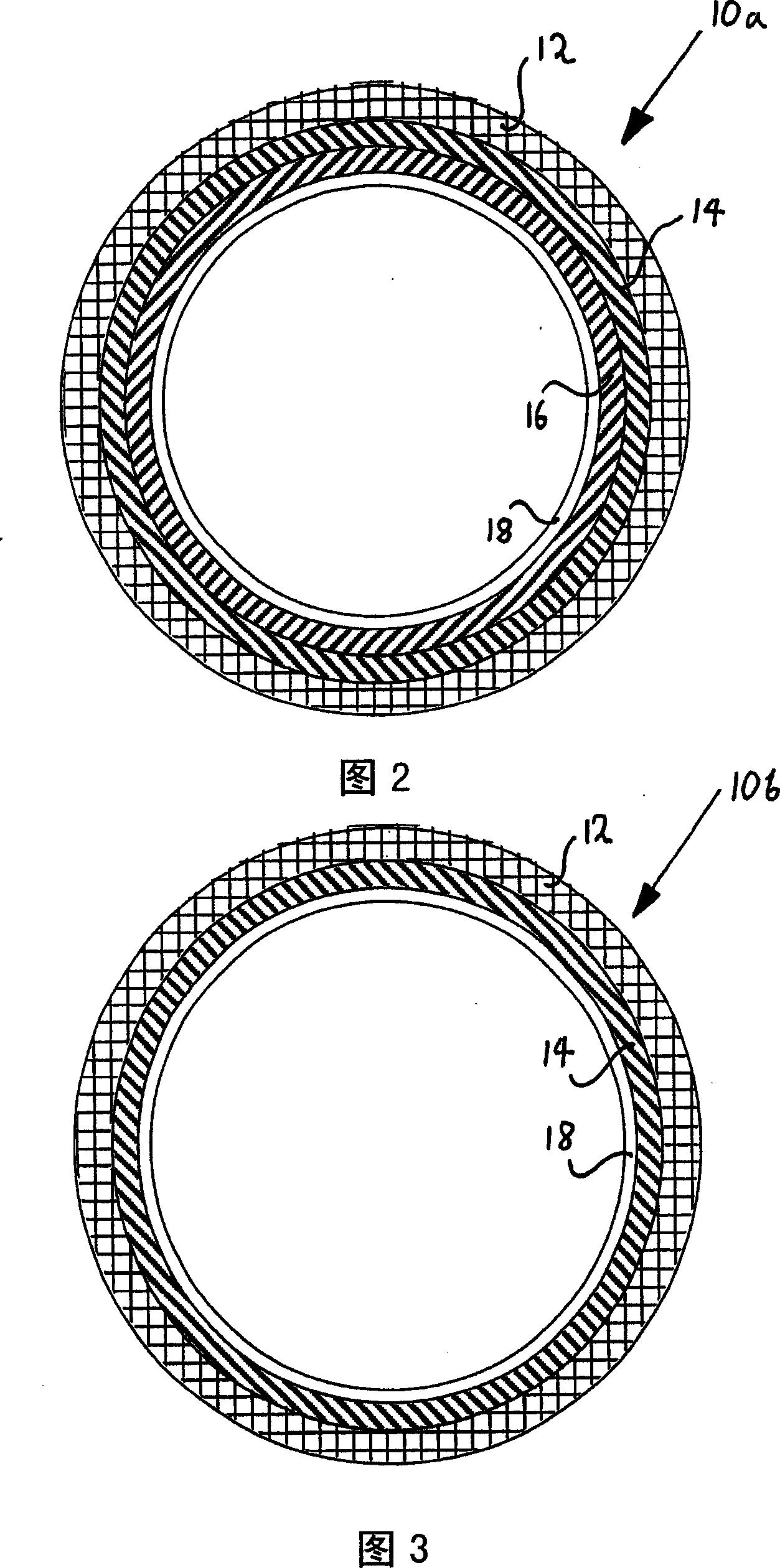

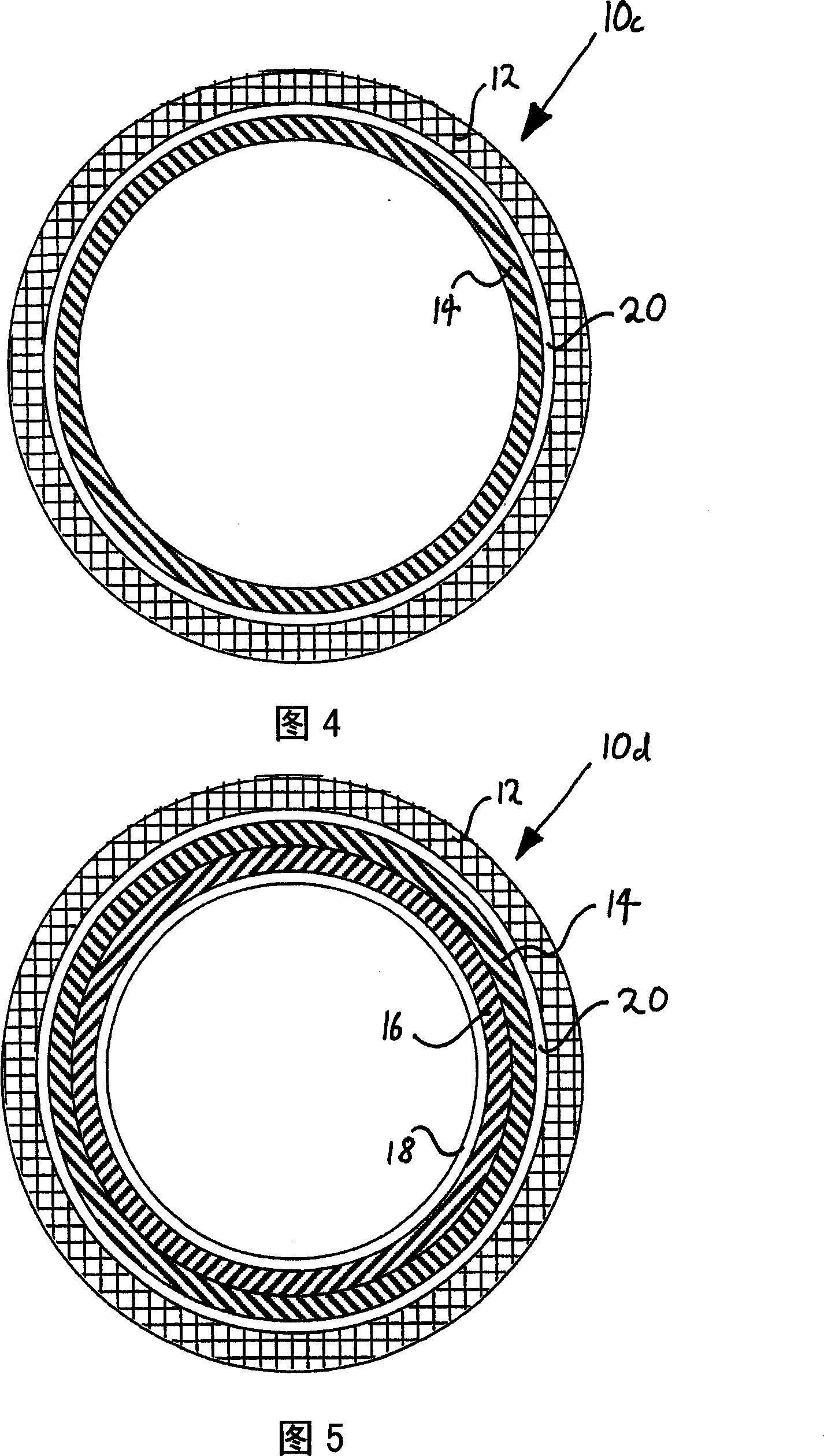

[0072] In Figures 1 and 2, the first embodiment of the composite liner is generally shown at 10a. In operation, the composite liner 10a is arranged in the main pipe 12. The liner 10a includes outer and inner structural layers 14, 16 for providing structural integrity, and a sealing layer 18 for providing fluid impermeability.

[0073] Each structural layer 14, 16 includes a lining strip tightly wound in a spiral shape, and each turn is substantially in contact with each adjacent turn. Thus, each strip forms a substantially continuous, cylindrical and tubular structure. The lining strip of the outer structural layer 14 is wound onto the inner surface of the main pipe 12 in the first spiral direction. Similarly, the lining strips of the inner structural layer 16 are wound onto the inner surface of the outer structural layer 14 in the opposite spiral direction.

[0074] Each liner strip 14, 16 has an appropriate thickness so that when wound, each liner strip 14, 16 forms a substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com