Electronic cigarette, battery device for electronic cigarette, power supply assembly and assembling method

A battery device and power supply component technology, which is applied in the field of electronic cigarettes, can solve problems such as affecting production efficiency, increasing production costs, and prone to breakage of wires, so as to achieve the effects of improving assembly efficiency, protecting battery devices, and reducing defective rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

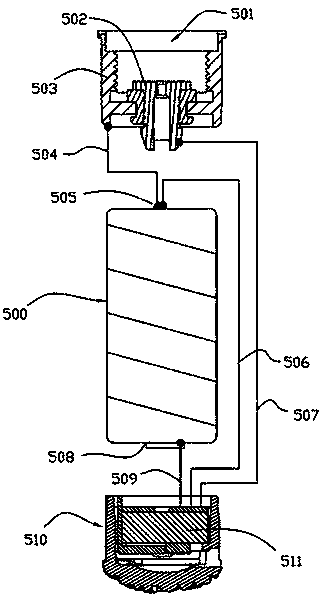

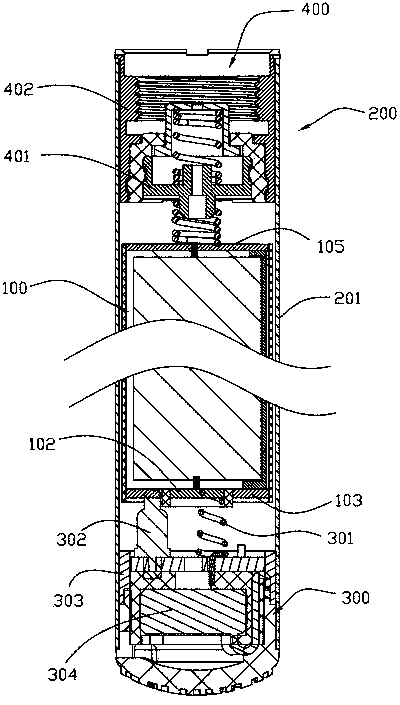

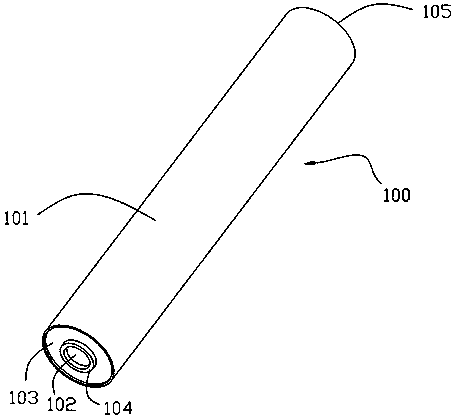

[0043] The power supply assembly involved in the present invention is formed by assembling three independent modules of the lampshade module, the battery device and the connecting member in the housing. There is no need for wire welding between each part, and direct contact conduction is adopted between each part, which is suitable for automatic assembly production. In order to adapt to automatic assembly, the lampshade module, battery device and connection components have been improved on the existing basis. The following is a specific embodiment of the overall structure of the above-mentioned lampshade module, battery device and connection components, and the power supply assembly. The working principle is further elaborated:

[0044] see figure 2 As shown, the power supply assembly 200 includes a housing 201, a lampshade module 300, a battery device 100 and a connecting member 400. The housing 201 is generally tubular and made of metal conductive material. The battery devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com