Modular LED panel lamp

A LED panel light, modular technology, applied in the direction of lighting and heating equipment, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of labor cost waste, increased assembly difficulty, easy to appear bright edges, etc., to achieve product structure Simple, reduce the assembly process, improve the effect of product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

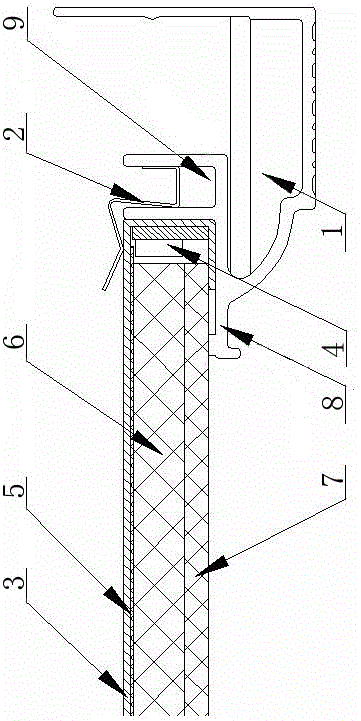

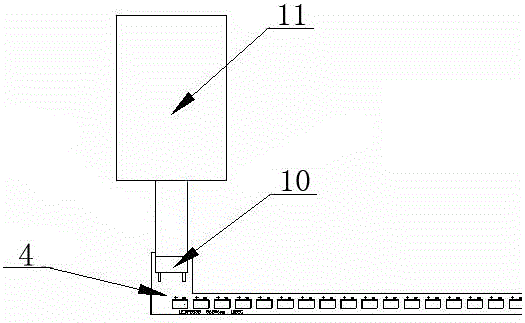

[0016] like Figure 1-2 As shown, the modular LED flat panel lamp of the present invention includes a lamp housing 1, a panel lamp group and a driving power supply 11. The driving power supply 11 is provided on the back of the lamp housing 1, and the panel lamp group is fixedly installed inside the lamp housing 1. The lamp housing 1 One side is equipped with a photosensitive switch to control the opening and closing of the LED light;

[0017] The panel lamp group includes a back plate 3, a light bar 4, a reflector 5, a light guide plate 6 and a diffuser plate 7. The back plate 3 is a cover with a card edge inwardly at the lower end, and the light bar 4 is fixedly installed on the back The inner edge of the cover of the plate 3, the reflective sheet 5, the light guide plate 6 and the diffusion plate 7 are sequentially placed inside the cover of the back plate 3 and fastened and fixed by the clamping edge at the lower end of the cover of the back plate 3 to form an overall modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com