Manufacturing process of high-density printed board with holes in pads

A processing technology and hole-in-disk technology, which is applied in the field of PCB manufacturing, can solve problems such as virtual welding or poor welding, and achieve the effect of improving quality, avoiding poor contact and virtual welding, and high-density packaging and connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

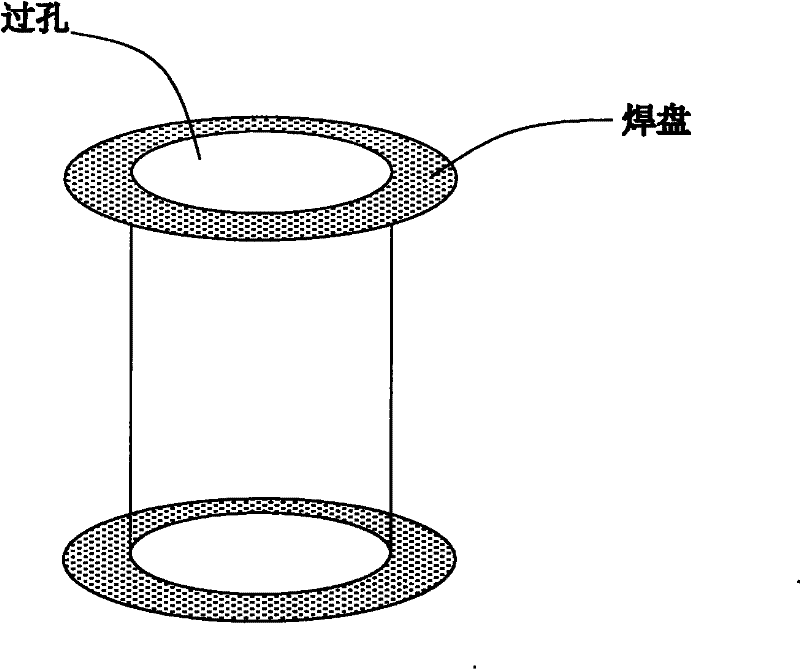

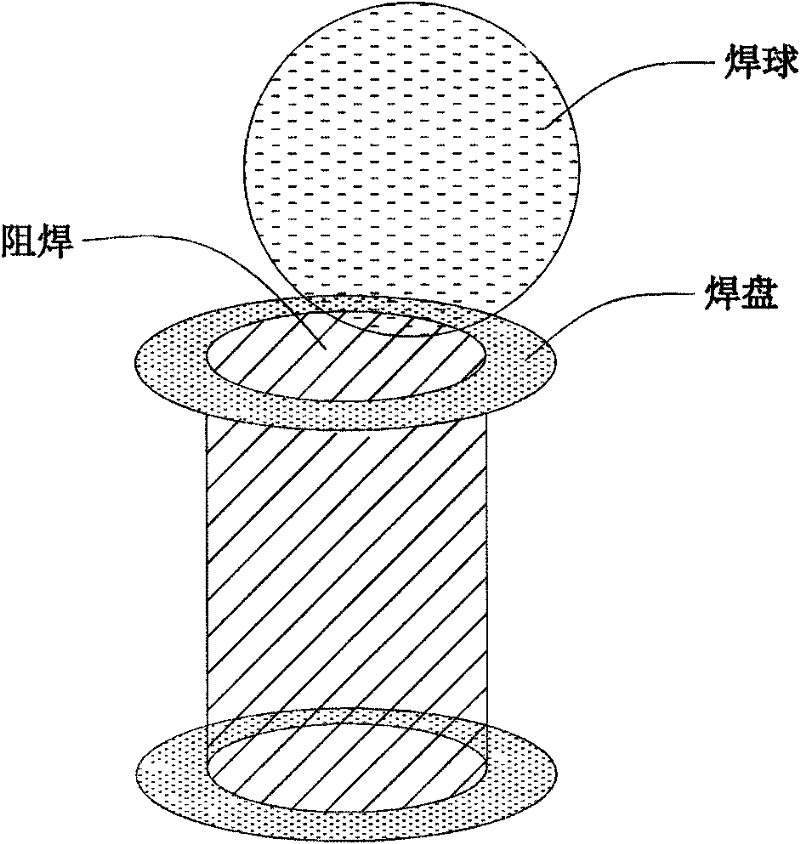

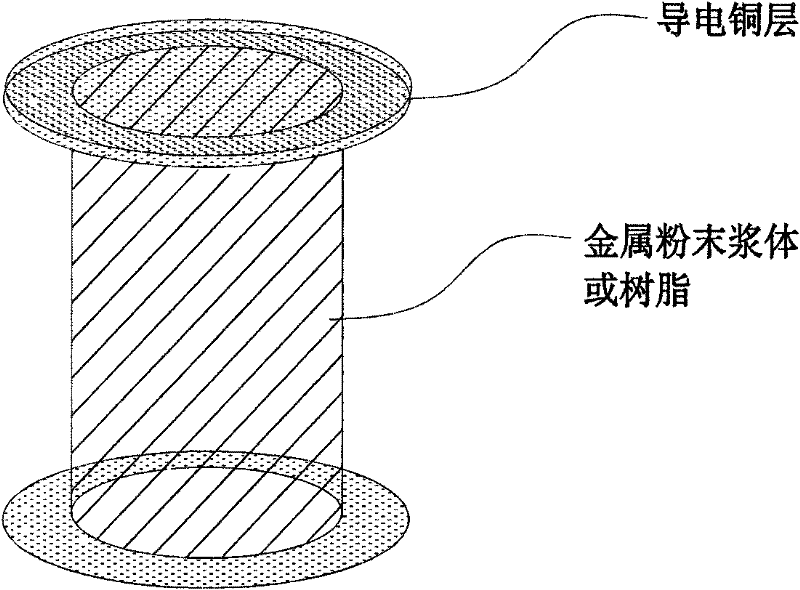

[0031] The core idea of the present invention is: by filling the slurry in the annular disc hole formed in the circuit board pad, the disc hole in the pad is filled to form a solid body, and the entire circuit board is welded by grinding. The slurry filled in the hole in the disk is flat and forms the same plane as the adjacent conductor surface, and then the circuit board is metallized and electroplated so that the upper and lower surfaces of the hole filled with the slurry are covered with a layer of conductive copper Layer, when the array solder balls or pins at the bottom of the BGA package device are connected to the pads of the above-mentioned holes in the pad, it can ensure sufficient contact with the pads and avoid the problems of weak soldering and virtual soldering.

[0032] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com