Point-supported PC wallboard connecting device

A technology for connecting devices and wall panels, applied to walls, building components, buildings, etc., can solve the problems of reducing the construction efficiency of construction projects, difficult positioning, and limited adjustment space, so as to improve the construction and installation efficiency, reduce the difficulty of processing, avoid The effect of welding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

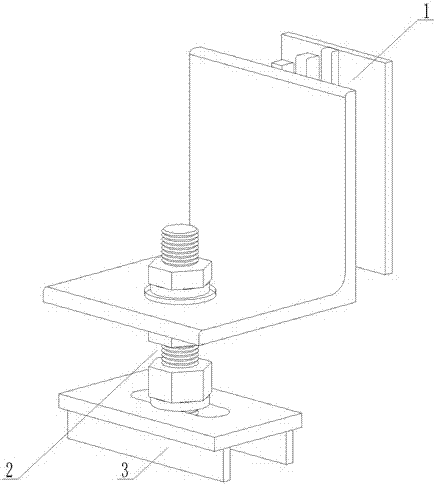

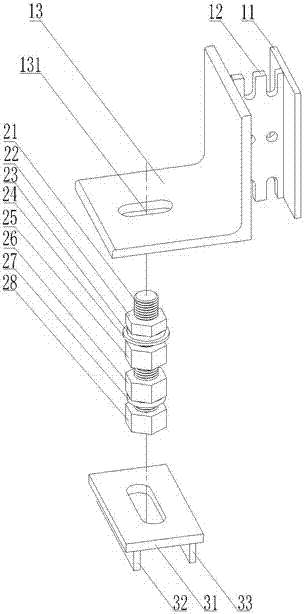

[0045] In this embodiment, a point-supported PC wall panel connection device is combined with figure 1 , including pre-embedded pendant 1, bolt set 2 and base 3; combined figure 2 , the pre-embedded pendant 1 includes a steel plate 11, a steel plate 2 12, and a steel plate 3 13 of an angle steel, wherein the steel plate 3 13 is provided with an oblong hole 131; the bolt kit 2 includes a full-threaded bolt 21, a nut 22, and a spring washer 23. Flat washer 1 24, adjusting nut 25, nut 2 26, spring washer 2 27 and bolt head 28, the lower end of the full-threaded bolt 21 is fixed on the base 3, and the upper end supports the pre-embedded pendant 1 through the steel plate 3 13, and can The height position of the entire bolt set 2 is adjusted by adjusting the nut 26 . And the setting of oblong hole one 131, under the cooperation with fully threaded bolt 21, nut one 22 and spring washer 23, flat washer 24 etc., realizes the front and back position adjustment of relative wallboard. ...

Embodiment 2

[0049] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference lies in: combining Figure 7 , the PC wallboard is pre-embedded with a pre-embedded pendant 1 and an auxiliary pre-embedded pendant 4, and the lower end of the pre-embedded pendant 1 is welded on the composite steel beam 8 through the bolt kit 2 and the base 3; the base angle steel 6 is set under the composite steel beam 8 , the base angle steel 6 is provided with a square hole, which is prefabricated and welded in the factory and fixed on the composite steel beam 8; the upper end of the auxiliary embedded pendant 4 is connected with the base angle steel 6 provided with a square hole through the auxiliary bolt set 5 and the sliding gasket, And fix it as a wind-resistant support, because the base angle steel 6 is provided with a square hole, which can slide in the horizontal direction and absorb interlayer displacement.

Embodiment 3

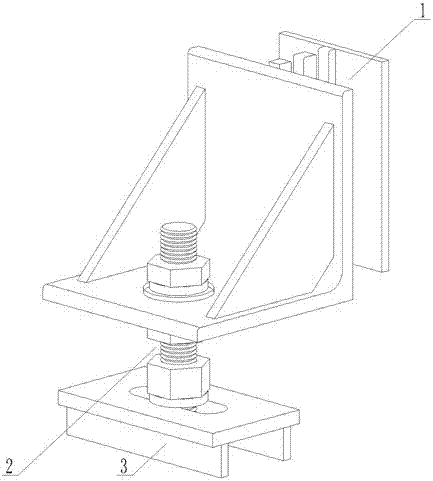

[0051] In this embodiment, a point-supported PC wall panel connection device is combined with image 3 , including pre-embedded pendant 1, bolt set 2 and base 3; combined Figure 4 , the pre-embedded pendant 1 includes steel plate 11, steel plate 2 12, steel plate 3 13, steel plate 4 14 and steel plate 5 15, steel plate 3 12 is an L-shaped angle steel structure, which is used as an exposed hooking part, and the side of the angle steel adopts steel plate 4 14 And steel plate 5 15 is used as a stiffening rib to strengthen the steel plate 3 13, that is, the right-angled root of the angle steel, which is safe, firm and reliable; at the same time, the exposed steel plate 3 13 is provided with a long hole 131 on the horizontal side, which is convenient for the front and rear direction adjustment of the bolt kit; Bolt kit 2 includes fully threaded bolt 21, nut 1 22, spring washer 1 23, flat washer 1 24, adjusting nut 25, nut 2 26, spring washer 2 27 and bolt head 28, and the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com