Method for determining safety handling time of cars and car production method

A safety processing and predetermined time technology, applied in the field of determining the safety processing time of vehicles, can solve the problem of inability to accurately determine the safety processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for determining the safe processing time of a vehicle, wherein the vehicle includes a window (or glass) that is bonded to the car body by an adhesive, and the safe processing time of any stage is from the bonding of the window Methods for determining the safe handling time of a vehicle from the time on the vehicle body to when the phase can begin include:

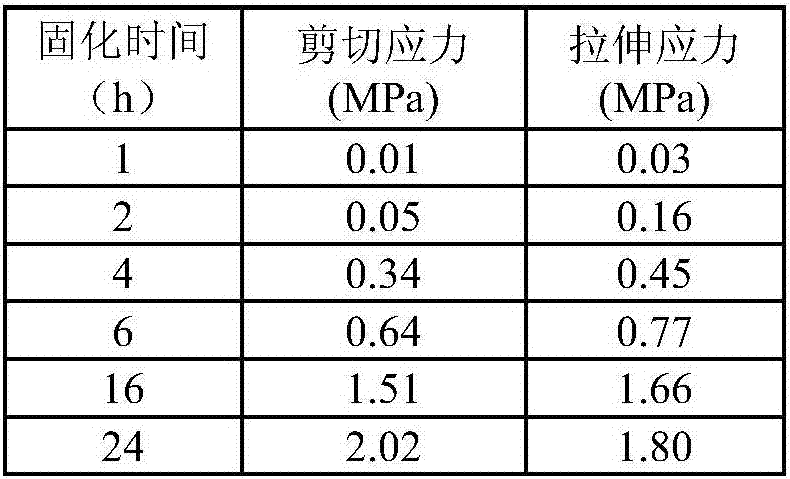

[0033] Calculate the maximum shear stress τ and maximum tensile stress σ of the window at the first stage according to the following formula: τ=m 1 (1+f 2 )×g×f 1 / (L×w×f 3 ), σ=m z ×g×f 1 / (L×w×f 3 ), where L is the perimeter of the window, w is the width of the bonding area of the window, m 1 is the mass of the window, m z is the equivalent mass causing the shear stress, g is the acceleration due to gravity, f 1 , f 2 , f 3 is the preset coefficient, f 1 ≥1, f 2 ≥0,0﹤f 3 <1;

[0034] The safe processing time of this stage is determined according to τ, σ and the pres...

Embodiment 2

[0037] This embodiment provides a method for determining the safe processing time of a vehicle.

[0038] Among them, some windows in the vehicle are bonded to the vehicle body by adhesive, and after the window is bonded to the vehicle body, the vehicle goes through other production stages. From the time the window is bonded to the car body, at least a certain amount of time must pass to ensure that the window has sufficient bond strength before each other stage can begin, and this time is the safe processing time for that stage .

[0039] Specifically, the above methods for determining the safe processing time of the vehicle include:

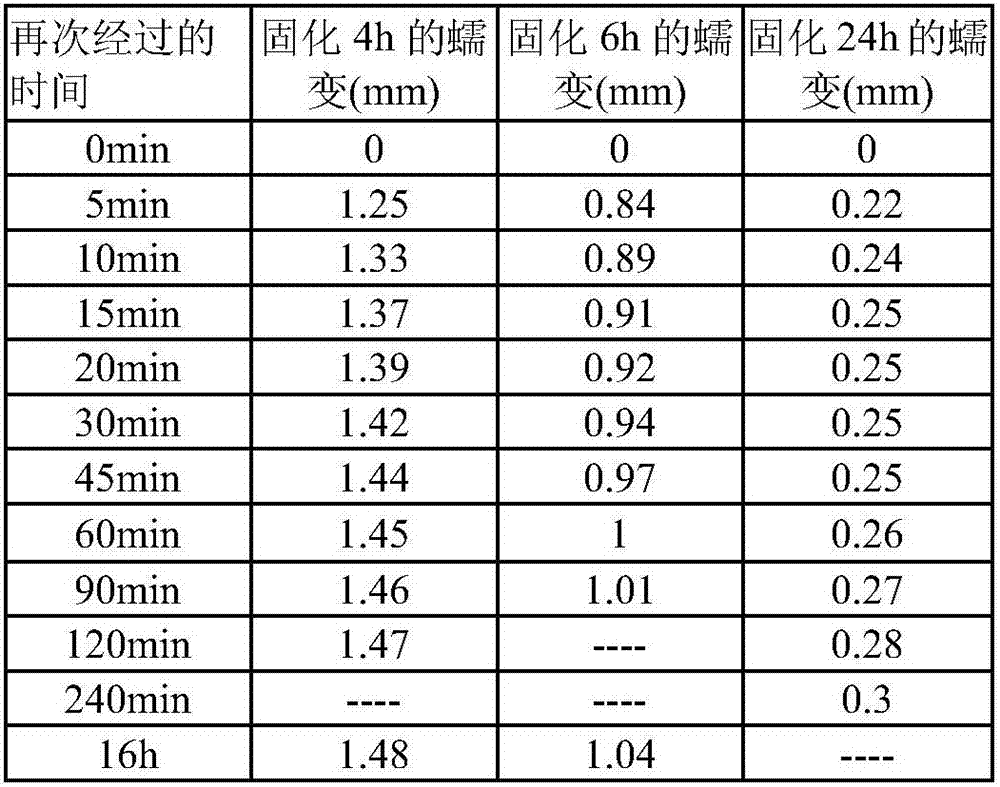

[0040] S11. Determine the safe processing time of the first stage of removing the adhesive fixture.

[0041] When the window is just bonded to the car body, the bonding strength is very low, so it needs to be temporarily fixed with a bonding fixture. Only when the bonding strength is sufficient can the bonding fixture be removed. The determinati...

Embodiment 3

[0117] This embodiment provides a method for producing a vehicle, wherein the vehicle includes a window bonded to the vehicle body by an adhesive,

[0118] In the vehicle production process, at least the safety processing time of this stage must pass before starting a stage, and the safety processing time is determined by the above-mentioned method.

[0119] That is to say, in the vehicle production process of this embodiment, after the window is bonded to the vehicle body, the subsequent process can only start after a corresponding safety treatment time. The security processing time of a stage must wait until the security processing time is reached before starting the next stage, and the security processing time of each stage is calculated according to the above method.

[0120] In the vehicle production method of this embodiment, the safety processing time is calculated according to the above method, so the safety processing time is the most accurate, which can ensure that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com