Polyurethane composition for high-surface-quality self-demolding automobile exterior trimming part material and application thereof

A composition and polyurethane technology, applied in the field of polyurethane, can solve problems affecting product surface quality, poor product surface quality, bagging, etc., to achieve outstanding hydrophobic and oil-repellent properties, surface anti-adhesion properties, excellent mechanical properties, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

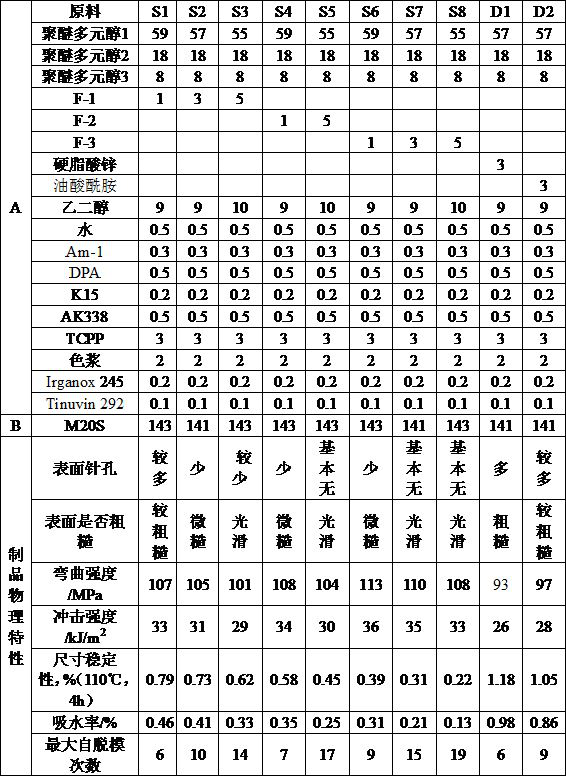

[0028] The invention is now further illustrated by, but not limited to, the following examples. The content of each component in the examples and comparative examples is unless otherwise specified, and the numerical unit of the raw materials used is parts by weight.

[0029] Raw materials used in the examples

[0030] Polyether polyol 1: sucrose and glycerin are mixed initiators, the polymerization unit is propylene oxide, the hydroxyl value is 450 mgKOH / g, and the functionality is 6.

[0031] Polyether polyol 2: Glycerin is the initiator, the polymerization unit is propylene oxide, the hydroxyl value is 470 mg KOH / g, and the functionality is 3.

[0032] Polyether polyol 3: glycerin as the initiator, grafted with propylene oxide, and capped with ethylene oxide, the hydroxyl value is 37 mgKOH / g, and the functionality is 3.

[0033] Chain Extender: Ethylene Glycol; Blowing Agent: Water; Catalyst 1: Pentamethyldiethylenetriamine

[0034] Catalyst 2: N-(dimethylaminopropyl) dii...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com