Process of electrically connecting electrodes of a photovoltaic panel

A photovoltaic panel and electrical connection technology, applied in the field of electrodes, can solve problems such as missing or misplaced solder bumps, photovoltaic breakage, etc., and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Features from different embodiments described below are examples of elements recited in the claims and may be combined together into one embodiment without departing from the scope of the claims.

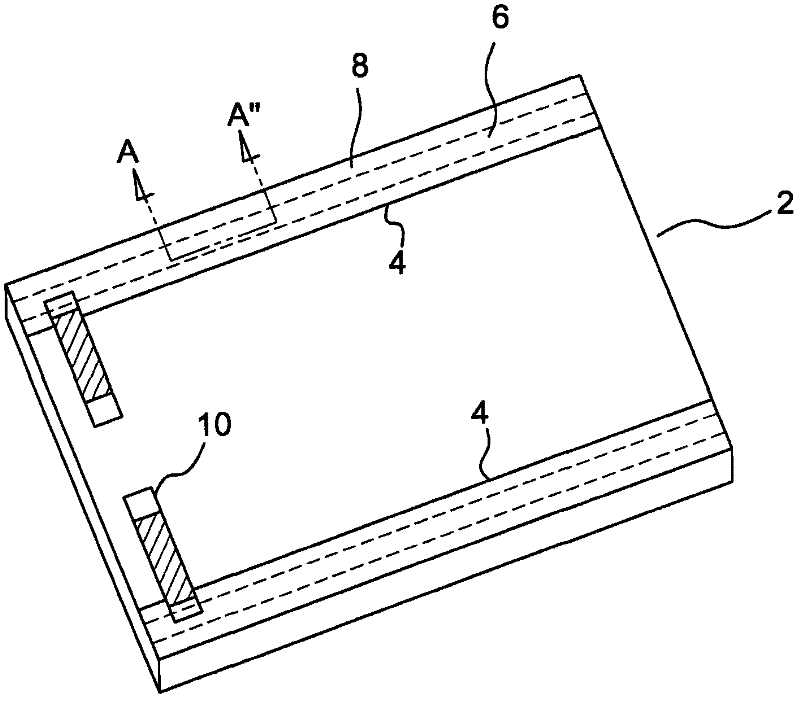

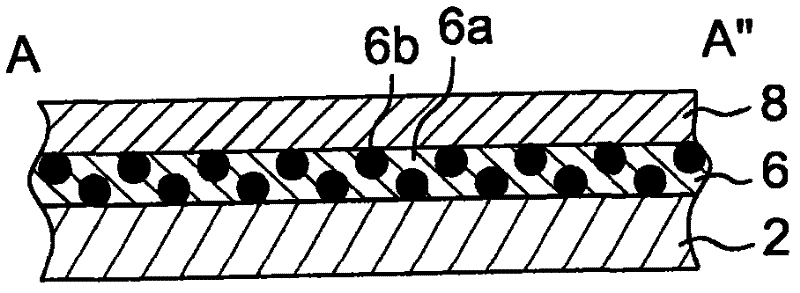

[0017] figure 1 A photovoltaic panel 2 is illustrated, which is electrically connected by a conductive adhesive film 6 on the electrodes of the photovoltaic panel 2 in the wire bonding area 4 and a metal strip 8 placed thereon. figure 2 yes figure 1 A cross-sectional view of a portion of the photovoltaic panel 2 depicted in .

[0018] Hereinafter, the method of the present invention will be described in detail for using a conductive adhesive film containing conductive particles.

[0019] The electrical connection method involves applying a conductive adhesive film 6 on the electrodes of the photovoltaic panel 2 . In one embodiment, conductive adhesive film 6 may be, but is not limited to, an anisotropic conductive adhesive film. The conductive adhesive film 6 includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com