Optimized indirect catalytic combustion flue gas multistage heat exchange system and process

A catalytic incineration and heat exchange system technology, applied in incinerators, combustion methods, gas treatment, etc., can solve the problems of increasing system processing gas volume, reducing catalyst life, affecting catalyst activity, etc., achieving a high degree of integration and heat exchange area The effect of minimizing and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

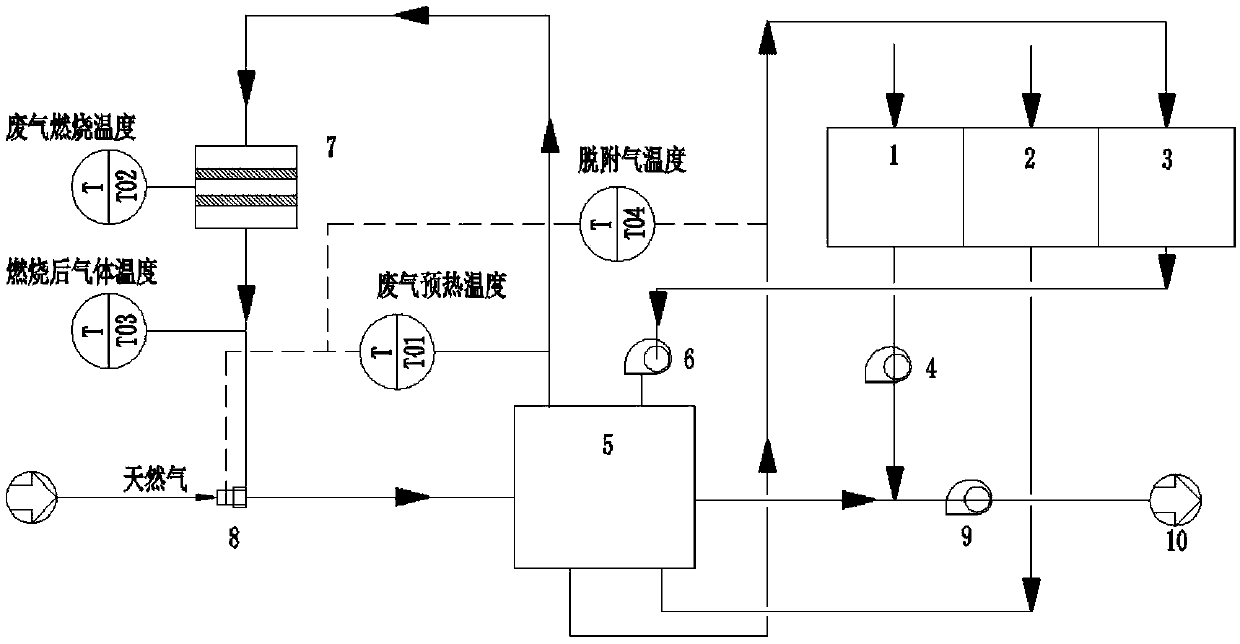

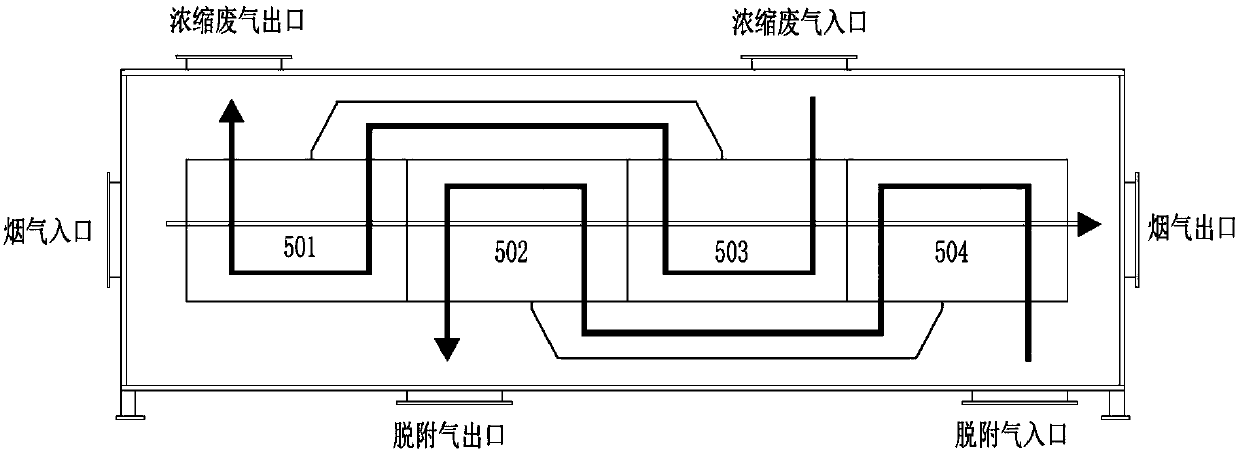

[0032] Such as figure 1As shown, an optimized indirect catalytic incineration flue gas multi-stage heat exchange system mainly includes a catalytic bed 7, a natural gas burner 8, a heat exchanger 5, an adsorption runner, an adsorption fan 4, a smoke exhaust fan 9 and Desorption fan 6. The heat exchanger 5 includes four-stage heat exchange units, which are respectively a first-stage heat exchange unit 501, a second-stage heat exchange unit 502, a third-stage heat exchange unit 503, and a fourth-stage heat exchange unit 504. The first-stage heat exchange unit 501 and the third-stage heat exchange unit 503 communicate with each other, the cold side outlet of the first-stage heat exchange unit 501 is used as the concentrated waste gas outlet, and the cold-side inlet of the third-stage heat exchange unit 503 is used as the concentrated waste gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com