Rapid and comprehensive evaluation method of lubricant oil aging performance

An aging performance and lubricating oil technology, applied in the direction of material inspection products, etc., can solve the problem of fast and comprehensive evaluation of oil aging performance, and achieve the effect of comprehensive aging performance evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

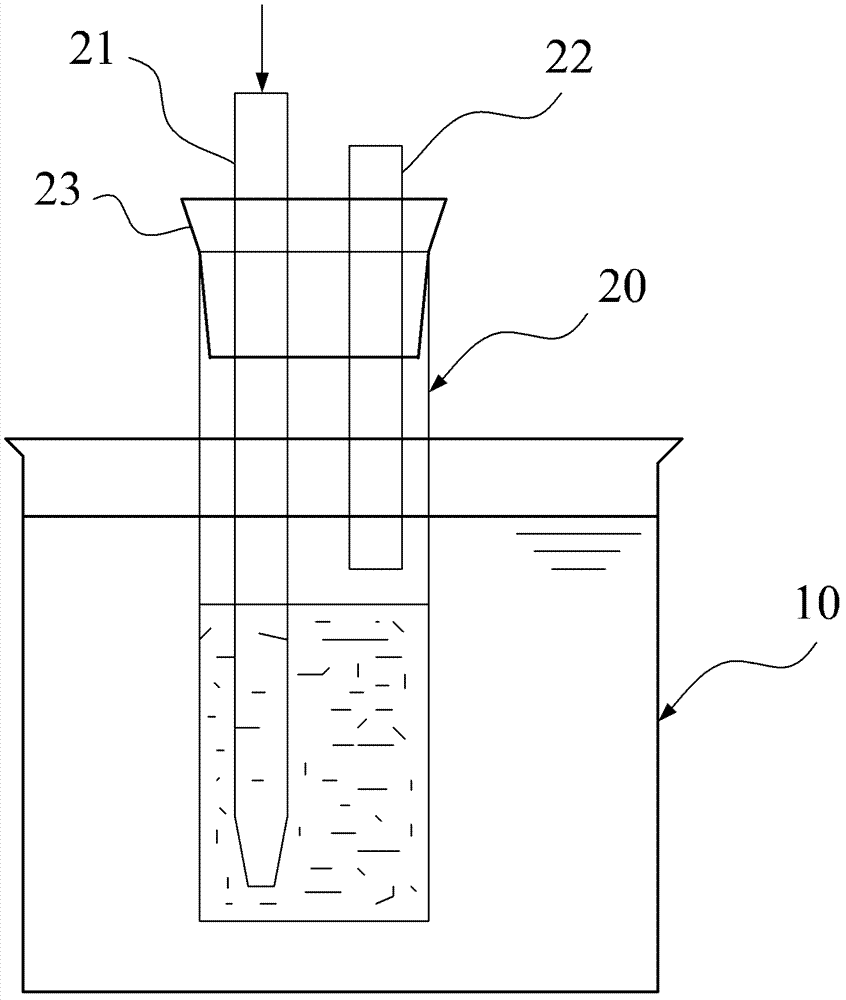

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is to use the evaluation method of the present invention to compare the aging performance of three hydraulic oil products A, B and C with similar properties in a relatively short period of time.

[0030] 1. Test conditions

[0031] The test temperature is 150°C, the air flow rate is 5L / h, and 5.5g copper sheet is added as a catalyst. The copper sheet is made of electrolytic copper with a purity greater than 99.9%. The width is 12.5mm, the thickness is 2.0mm, and the length is 75mm; the test period 120h, testing items include viscosity, viscosity index, color and acid value.

[0032] 2. Test sample

[0033] Oil product A: wherein the base oil is composed of API type I oil and API type II oil, the weight ratio of the two is 8:1; the weight percentage of antiwear agent is 1% of the total amount.

[0034] Oil product B: wherein the base oil is composed of API type I oil and API type II oil, the weight ratio of the two is 5:1; the weight percentage of antiw...

Embodiment 2

[0044] This embodiment is to use the evaluation method of the present invention to carry out a comprehensive aging performance comparison of three oil products.

[0045] 1. Test conditions

[0046] (1) Test temperature: 150°C;

[0047] (2) Test air source: compressed air, the flow rate is 5L / h;

[0048] (3) Catalyst: copper sheet, electrolytic copper with a purity greater than 99.9%, with a width of 12.5 mm, a thickness of 1.5-3.0 mm, and a length of 75 mm;

[0049] (4) Test period: 168 hours;

[0050] (5) Analysis items: viscosity, chroma, acid value, emulsification resistance, pentane insoluble matter, copper corrosion, copper weight loss and sludge trend.

[0051] 2. Test sample

[0052] Oil product A, oil product B and oil product C, the oil product is the same as embodiment 1.

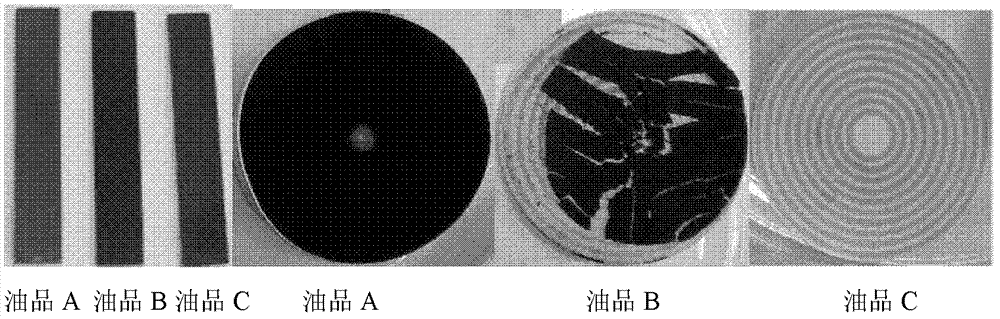

[0053] 3. Test results

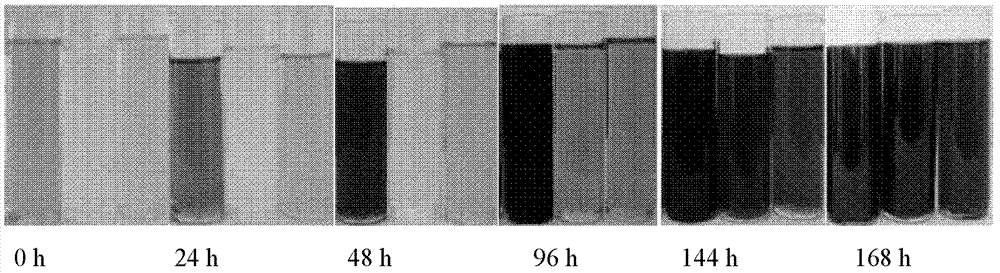

[0054] 3.1 Oil appearance

[0055] figure 2 It shows how the oil appearance changes with aging time.

[0056] Depend on figure 2 It can be seen that the appear...

Embodiment 3

[0071] In order to compare the difference between the test method established by the present invention and the existing method in evaluating the anti-aging performance of lubricating oil, the test method of the present invention and the most commonly used method in the industry (GB / T 12581-2006 plus inhibitor mineral oil oxidation characteristics Determination method) the anti-aging performance of A, B, C three kinds of oil products (oil product is the same as embodiment 1) has been evaluated.

[0072] The GB / T 12581 method is to react the sample with oxygen at 95°C in the presence of water and copper-iron catalyst, and use the time required for the acid value to reach 2.0mgKOH / g or after a certain reaction time for a certain oil product The acid value change is used to characterize the oxidation stability of the oil. For the oil product investigated in this patent, according to the requirements of the national standard, the reaction time is 1000h, and the oxidation stability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com