Method for reducing quenching-oil viscosity of ethene producer

A technology for ethylene plant and quenching oil, which is applied in the fields of hydrocarbon cracking, hydrocarbon production, organic chemistry, etc. It can solve the problems of high viscosity and achieve the effects of reducing energy consumption, increasing the amount of steam generated, and reducing the amount of replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

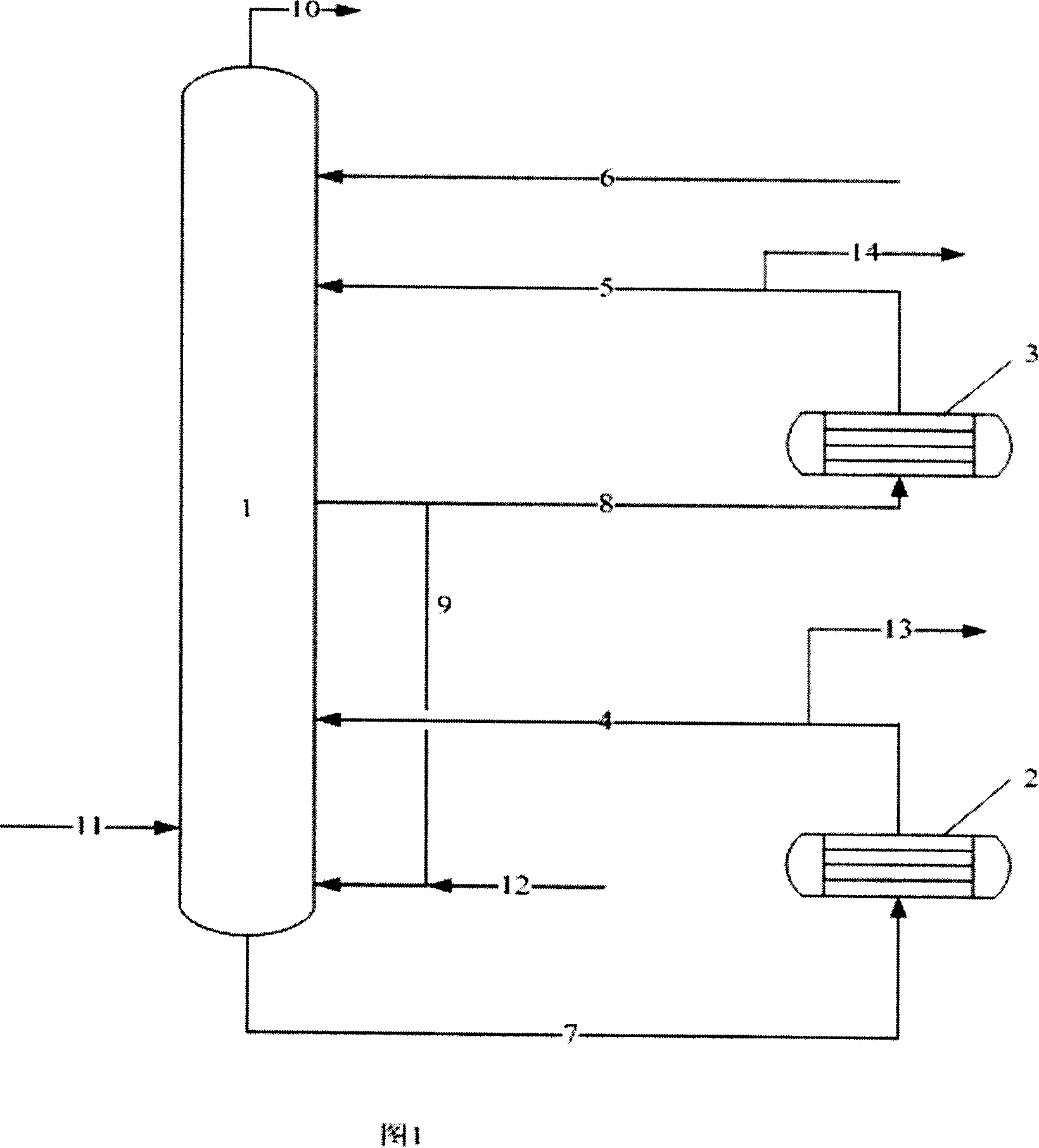

[0025] The quenching system shown in Figure 1 is adopted, and the main equipment includes an oil washing tower 1, a quenching oil heat exchanger 2 and a pan oil heat exchanger 3.

[0026] The cracked gas from the outlet of the cracking furnace is preliminarily cooled to 230°C and sent to the bottom of the oil washing tower 1 through the pipeline 11, and is cooled by three reflux streams of 4, 5 and 6, and the heaviest quenching oil component in the material condenses to the bottom of the tower to form a quenching Oil, quenching oil enters the heat exchanger 2 through the pipeline 7 for cooling, most of it returns to the oil washing tower 1 through the pipeline 4, and a small part is sent out through the pipeline 13.

[0027] The pan oil produced in the middle of the oil washing tower 1 enters the heat exchanger 3 to be cooled through the pipeline 8, most of it returns to the oil washing tower 1 through the pipeline 5, part of the pan oil is mixed into the bottom of the tower th...

Embodiment 2

[0031] Add viscosity reducer in the quenching oil circulation system: the viscosity reducer enters the bottom of the oil washing tower 1 through the pipeline 12 together with the pan oil in the pipeline 9 to jointly adjust the viscosity of the quenching oil.

[0032] Add a viscosity reducer to the middle pan oil that is blended into the bottom of the tower to adjust the viscosity. The weight percentage of each component in the viscosity reducer is: 20% dodecylbenzenesulfonic acid, 15% dispersant, N.N diethyl Hydroxylamine 12%, water treatment agent 12%, 2.6-di-tert-butyl p-cresol 5%, quench oil antioxidant 10%, petroleum refining corrosion inhibitor 16%, hydrocarbon solvent (C 9 )10%. The injection concentration of viscosity reducer is 6-10ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com