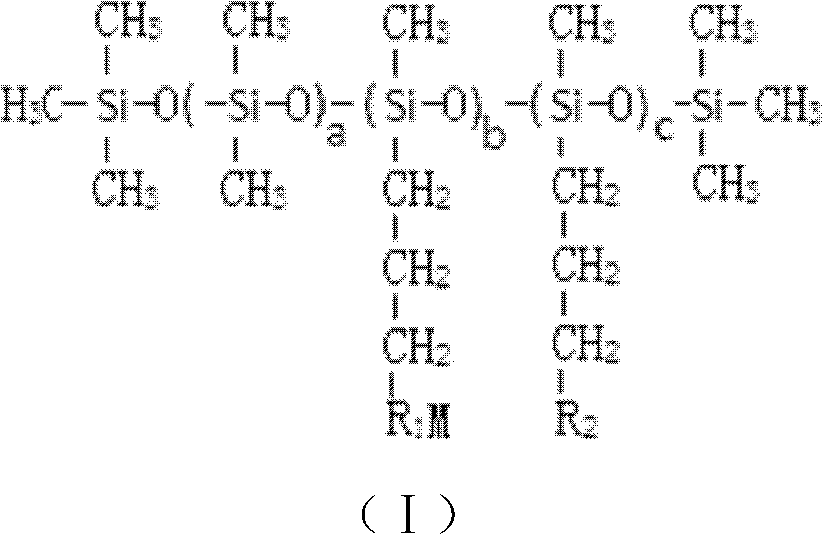

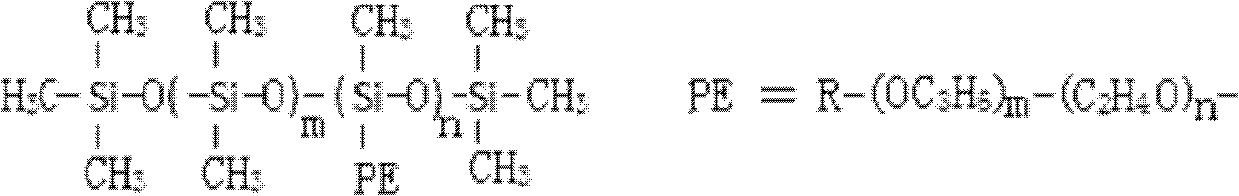

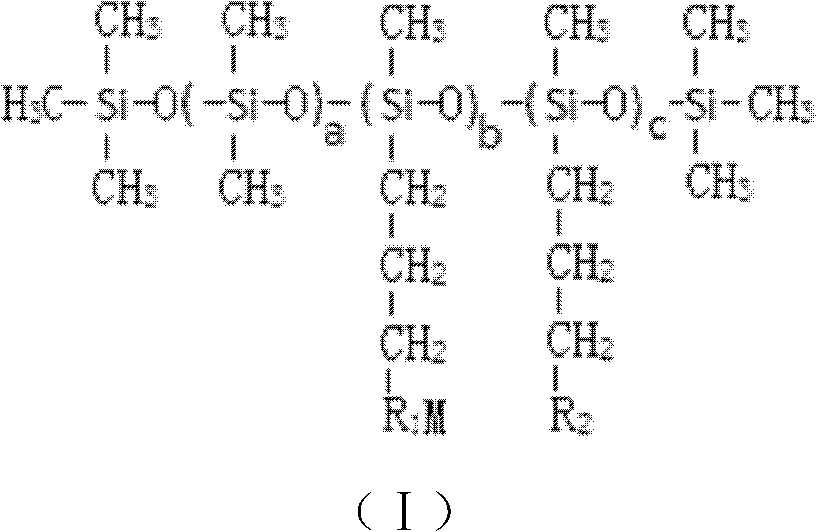

Comb-shaped modified polysiloxane anion water-base thick oil viscosity reducer and synthesizing method thereof

A thick oil viscosity reducer, polysiloxane technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of inability to form an electric double layer, poor temperature and hydrolysis resistance, poor dispersion stability, etc. problem, to achieve the effect of enhanced salt resistance, good dispersion and viscosity reduction effect, and enhanced affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix 90g of polymethylhydrogensiloxane (mass fraction of active hydrogen 1.55%), 50g of hexamethyldisiloxane, 100g of octamethylcyclotetrasiloxane, 4.8g of concentrated sulfuric acid, and stir at 60°C for 3 hours , lower the temperature to 30°C, add solid sodium bicarbonate to neutralize to neutrality, then depressurize at -0.04MPa at 90°C to remove moisture and low boilers, and filter to obtain methyl hydrogen-containing silicone oil intermediate 1; take 70g of the intermediate 1. 16.8g of n-dodecene, 160g of allyl polyoxyethylene ether (M=500), adding 20ppm of chloroplatinic acid catalyst, and reacting at 100°C for 2 hours to obtain a comb-shaped structure modified polysiloxane intermediate 2; Take 125g of intermediate 2, 30g of sodium isethionate, and 1.0g of potassium hydroxide, and heat it at 170-180°C for 15 hours under reduced pressure for dehydration to obtain viscous comb-shaped structure modified polysiloxane polyether sulfonic acid sodium. The product is adde...

Embodiment 2

[0036] Mix 120g of polymethylhydrogensiloxane (active hydrogen mass fraction 1.55%), 20g of hexamethyldisiloxane, and 2.8g of concentrated sulfuric acid at 80°C for 2 hours, then cool down to 30°C and add solid sodium bicarbonate Neutralize to neutral, then remove moisture and low boilers under reduced pressure at 100°C -0.03Mpa, filter to obtain methyl hydrogen-containing silicone oil intermediate 1; take 80g intermediate 1, 44.9g n-hexadecene, 180g allyl Polyoxyethylene ether (M=300), add 30ppm chloroplatinic acid catalyst, react at 110°C for 1 hour to obtain comb-shaped structure modified polysiloxane intermediate 2; take 160g of intermediate 2, 35g of sodium chloroacetate, 12g of sodium, heated and reacted at 40-50°C for 4 hours to obtain viscous comb-shaped structure modified polysiloxane polyether sodium acetate. After the product is neutralized, water is added to prepare a product with a solid content of 30%. The product in Example 3 was prepared into 0.5% aqueous solu...

Embodiment 3

[0039] Mix 50g of polymethylhydrogensiloxane (mass fraction of active hydrogen 1.55%), 10g of hexamethyldisiloxane, 90g of octamethylcyclotetrasiloxane, 3.0g of concentrated sulfuric acid, and stir at 70°C for 2 hours , lower the temperature to 30°C and add solid sodium bicarbonate to neutralize to neutral, then decompress at 100°C to -0.03Mpa to remove moisture and low boilers, and filter to obtain methyl hydrogen-containing silicone oil intermediate 1; take 18g of intermediate 1, 12.6 g n-octadecene, 75g allyl polyoxypropylene (10) ethylene (10) ether (M=1050), add 30ppm chloroplatinic acid catalyst, react at 130°C for 1 hour to obtain comb-shaped structure modified polysiloxane Intermediate 2: Heat 105 g of Intermediate 2 and 7.0 g of phosphorus pentoxide at 80°C for 4 hours, add 20 g of water, hydrolyze at 60°C for 1 hour, add 30% sodium hydroxide solution to neutralize to pH = 7, and obtain Viscous comb structure modified polysiloxane polyether sodium phosphate. The prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com