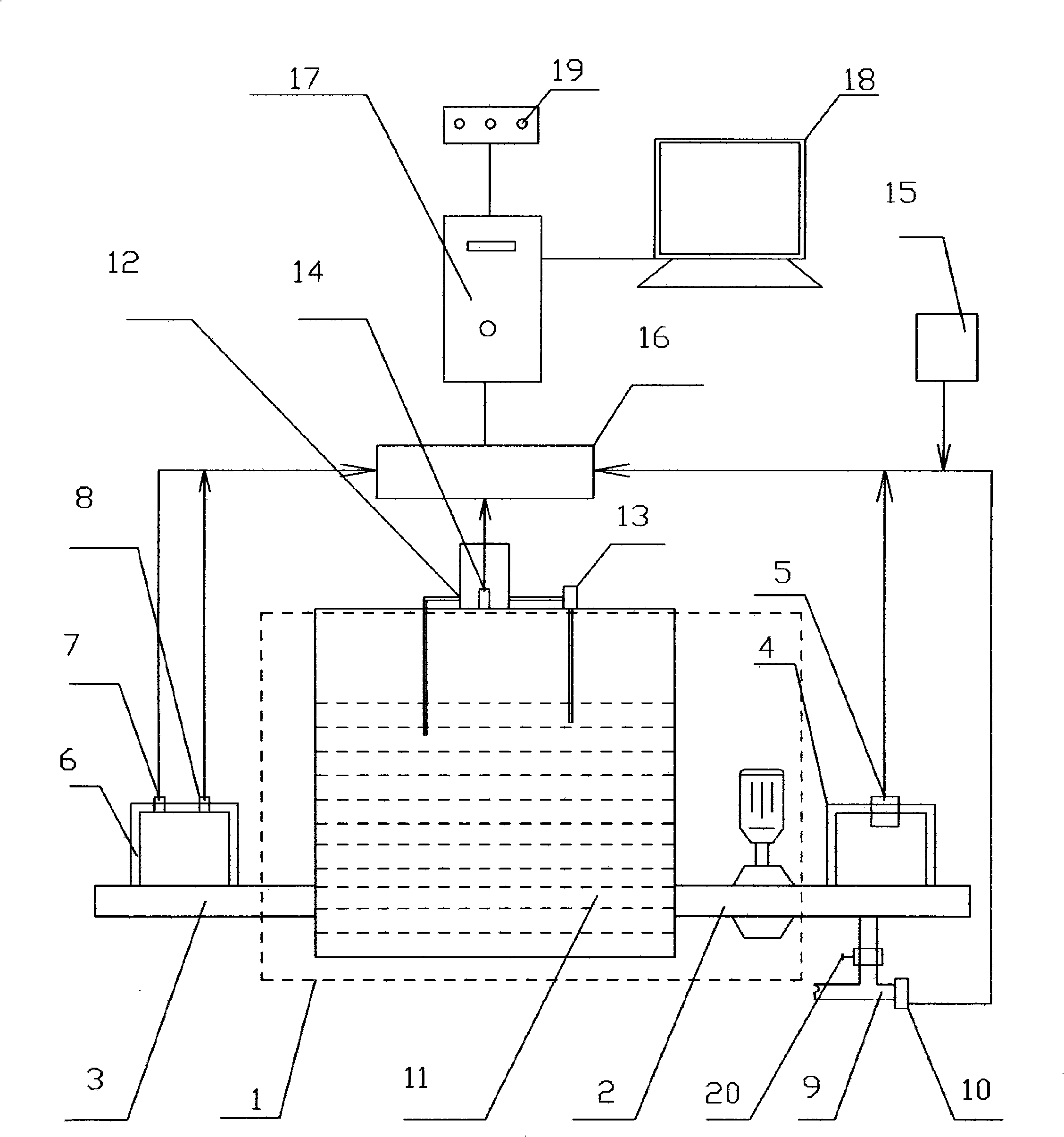

System and method for on-line monitoring hydraulic oil and lubricant oil conditions

A technology of monitoring system and environmental monitoring system, which is applied in the field of online monitoring system of hydraulic oil and lubricating oil, which can solve the problems of excessive moisture in oil, decreased wear resistance, oxidation failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

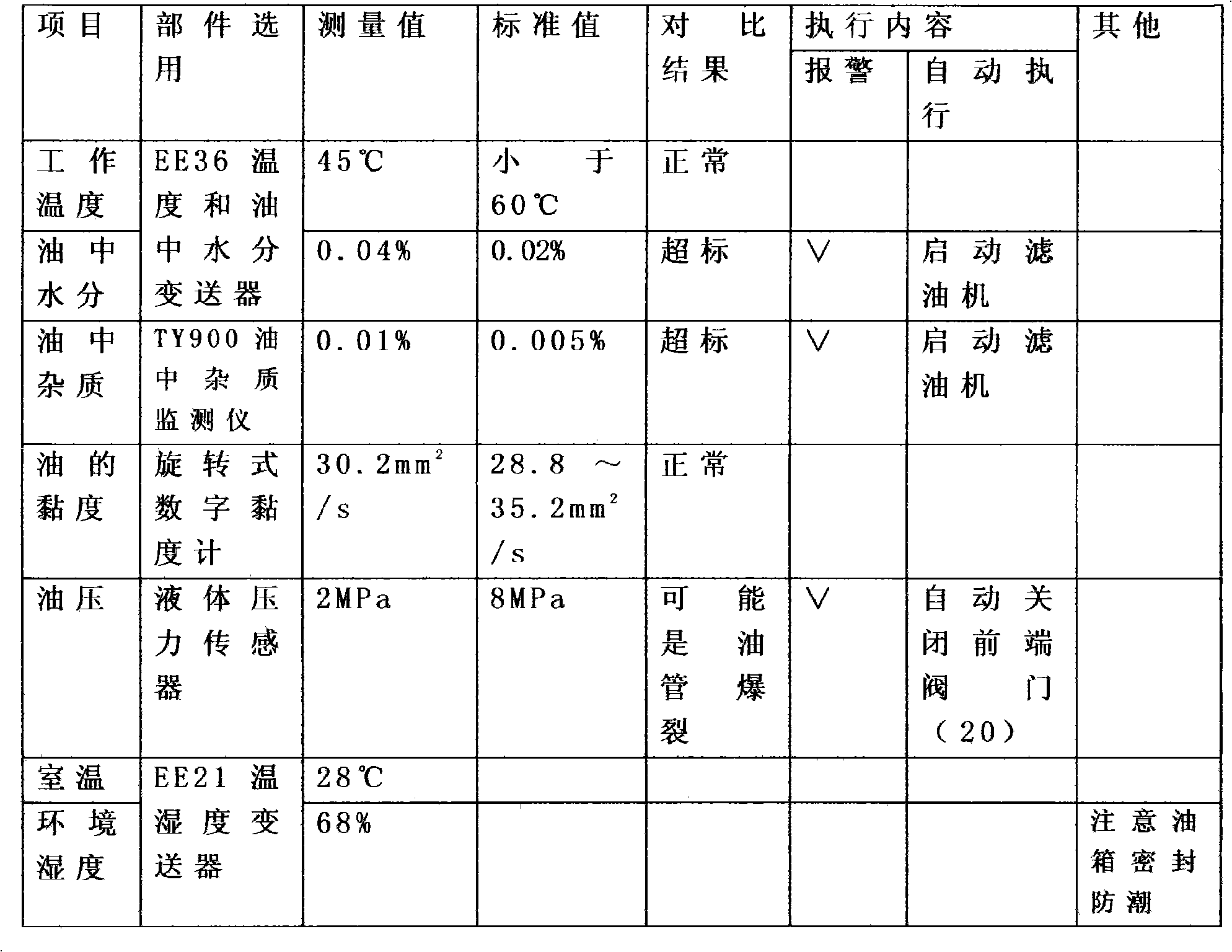

[0040] Take the continuous casting hydraulic station of a steelmaking plant as an example: N 32 Great Wall brand 4632 ester type flame retardant hydraulic oil is used, and the standard kinematic viscosity is 28.8~35.2mm 2 / s, the allowable water content is 0.02%, the allowable impurity content is 0.005%, the allowable working temperature is below 60°C, and the working pressure is 8MPa.

[0041] Set the monitor, sensor and monitoring system according to the above method, and the monitoring results at a certain time are as follows:

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com