Screenless flow-through battery material dryer

A battery material and dryer technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of house construction, operation and equipment maintenance, unsmooth air flow, and powder blockage of the screen, etc., to achieve Reliable drying effect, convenient manufacturing and installation, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

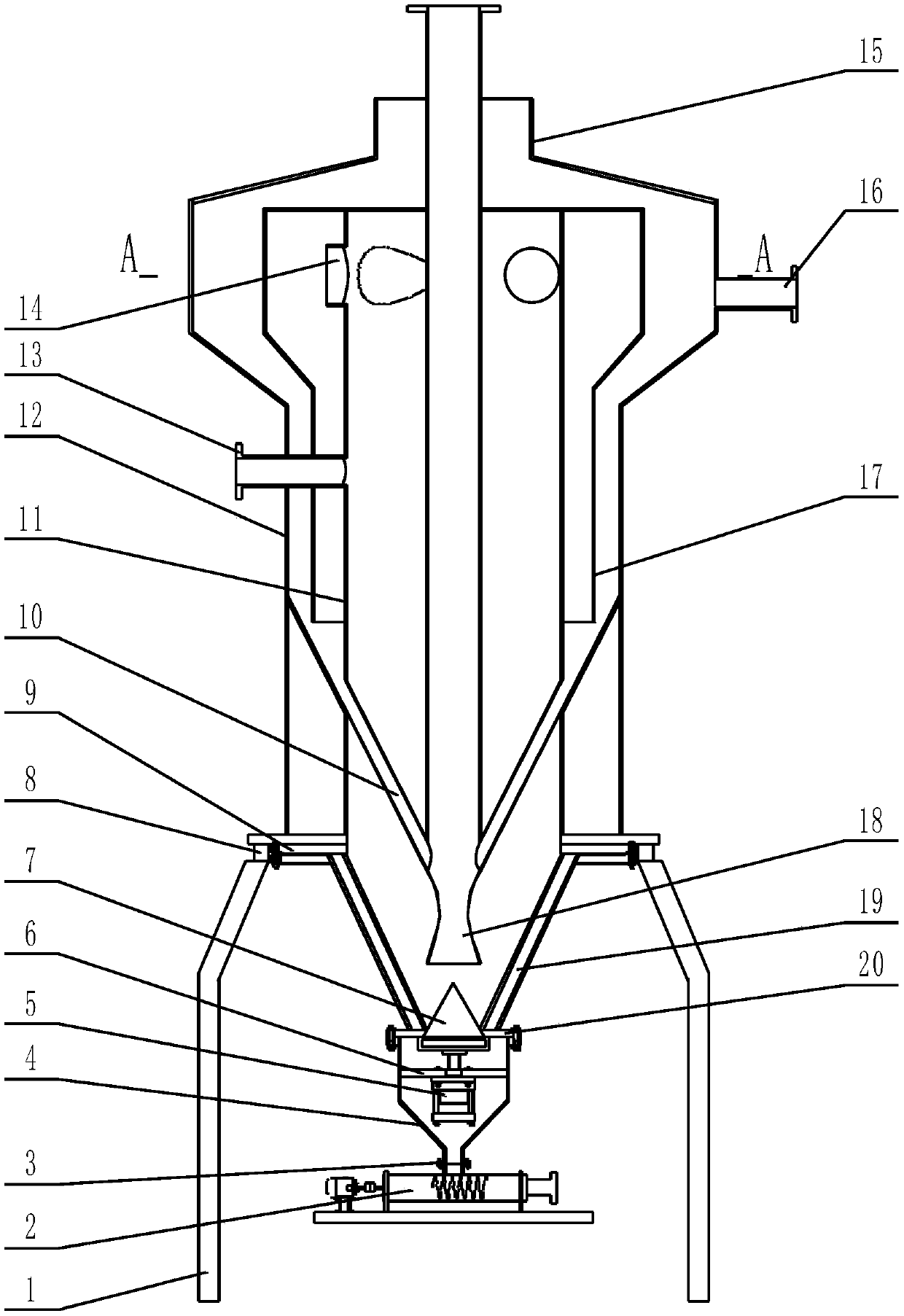

[0021] The present invention has no sieve mesh flow-washing type battery material drier (abbreviation drier, see figure 1 ) includes bracket 1, screw feeder 2, first flange 3, discharge pipe 4, cylinder 5, blanking plate 6, sealing piston 7, weighing device 8, second flange 9, venturi branch 10 , air flow tank (not marked in the figure), return air tank 12, feed pipe 13, cyclone outlet pipe 14, return air pipe 15, vacuum tube 16, return tank 17, Venturi tube 18 and the third flange 20;

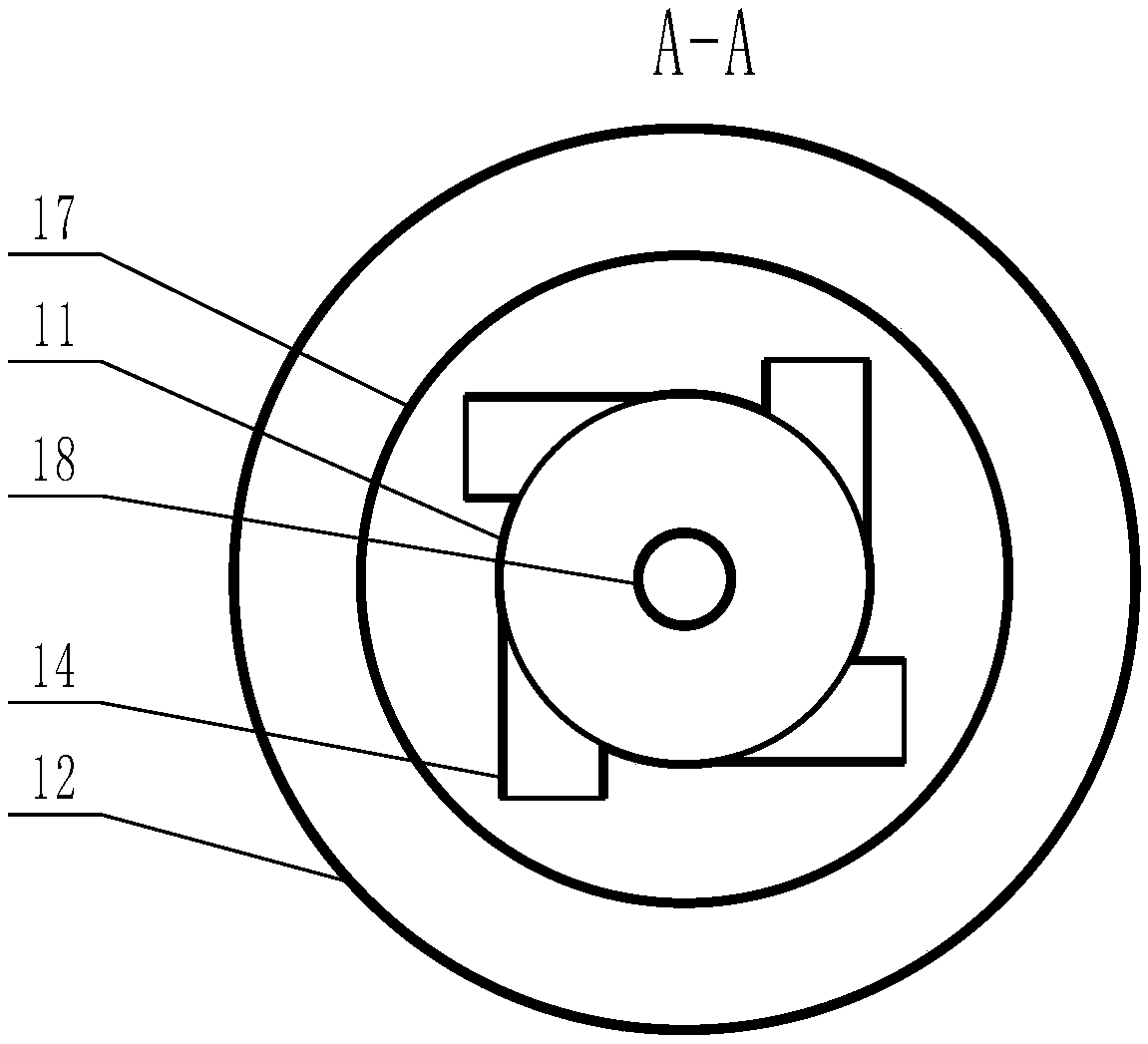

[0022] Described airflow jar comprises airflow jar upper section 11 and airflow jar lower section 19, and airflow jar upper section 11 and airflow jar lower section 19 are communicated, and the upper outside of airflow jar upper section 11 is set return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com