Screenless processing technology for printing roller

A processing technology and technology of plate rollers, which is applied in the field of non-mesh processing technology for plate rolls, can solve the problems of increasing raw material costs, production cycle production costs and production efficiency, parameters cannot be engraved at the same time, and engraving depth is shallow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

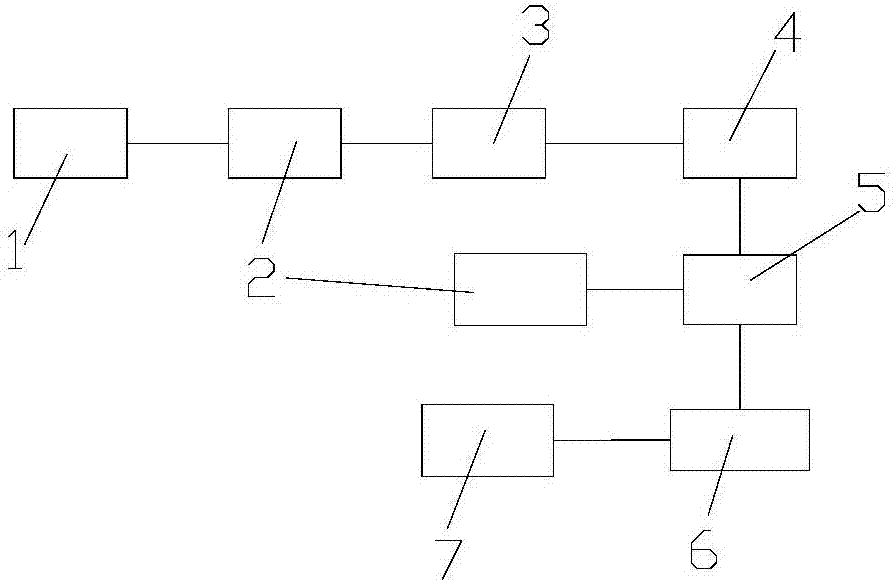

Image

Examples

experiment example 1

[0017] (1) Copper plating treatment: Copper plating is performed on the surface of the processed version roller, the specific steps are: A. Put the version roller in an ultrasonic cleaning machine for cleaning, and remove the machine oil remaining on the surface of the version roller during the production process of the version roller For debris, the cleaning frequency of the ultrasonic cleaning machine is 40KHz, and the cleaning time is 3-5 minutes. After cleaning, take out the plate roller and dry it; B. Place the plating tank in the ultrasonic generator, and add electroplating solution to the plating tank , put the plate roller washed and dried in step A into the electroplating solution, the copper plating temperature is 50 degrees Celsius, the frequency of the ultrasonic generator is 50KHz, the electroplating time is 10min, and the current density is 10A / dm2. After the electroplating is completed, the The plate roller is taken out and cleaned;

[0018] (2) Grinding and pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com