Drying apparatus for manufacturing pressure-sensitive adhesive tape

A technology of pressure-sensitive adhesives and drying equipment, which is applied in the direction of film/sheet adhesives, drying, drying machines, etc., which can solve the problems of equipment enlargement and length of conveyor belt substrate, etc., and achieve Reliable drying results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention are described with reference to the drawings.

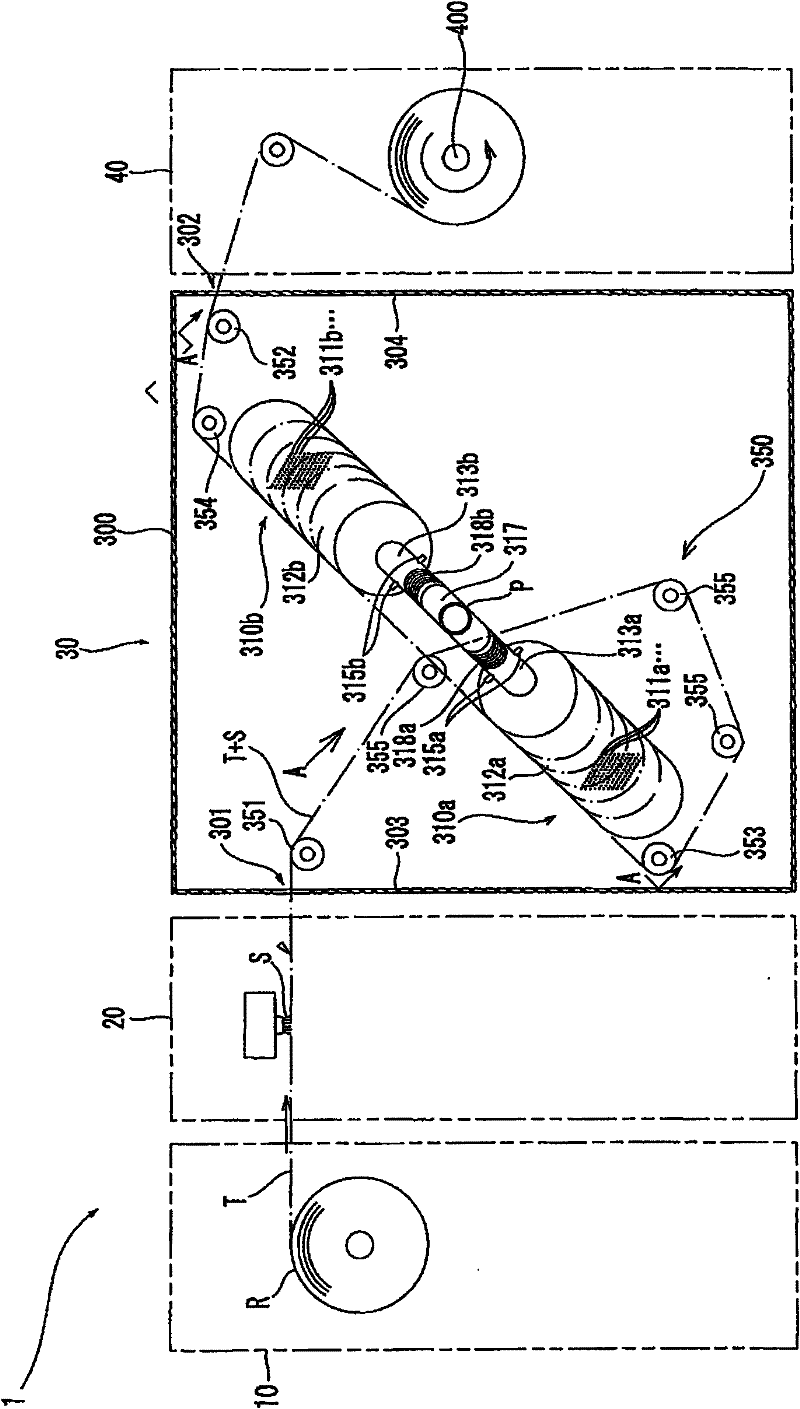

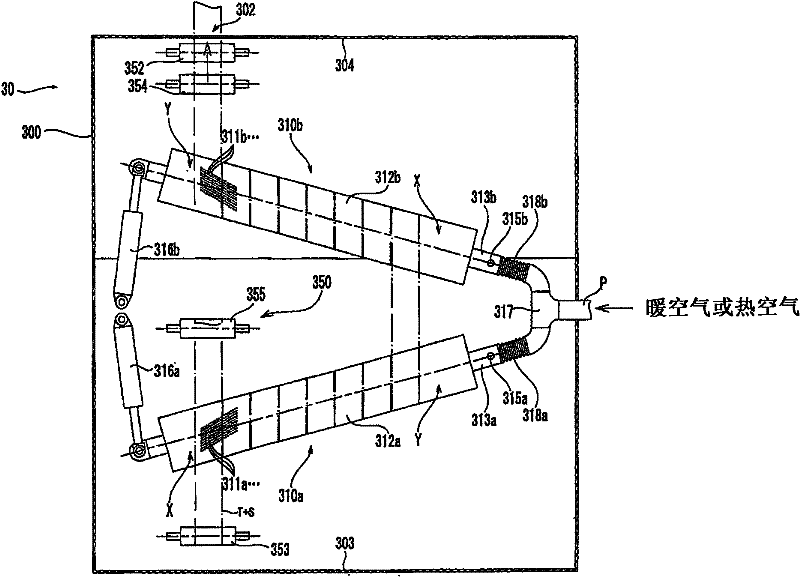

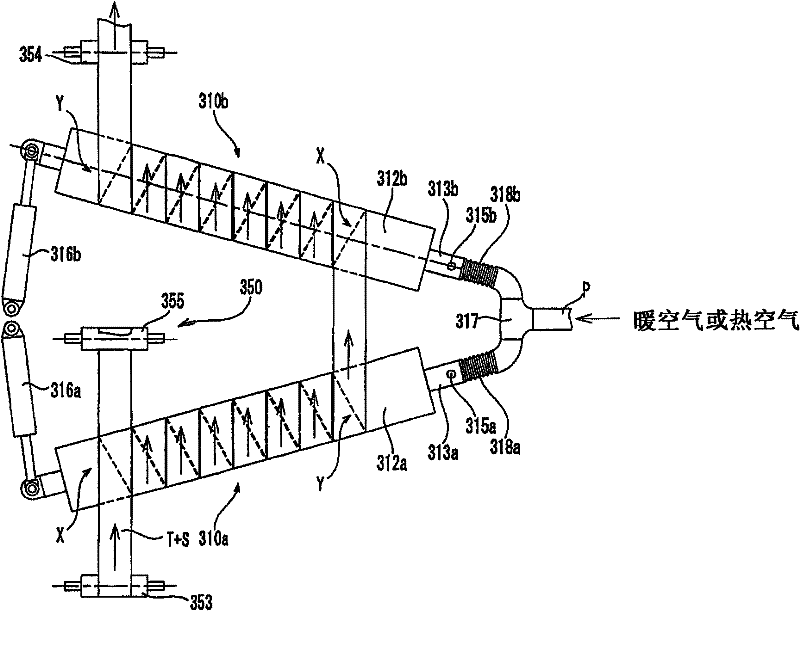

[0041] Such as figure 1 As shown in , a manufacturing facility 1 for manufacturing a pressure-sensitive adhesive tape includes a feeding device 10 that accommodates a roll (roll) R, and a strip-shaped tape substrate T in the feeding device 10 Wrapped around said reel R, and said feeding device 10 feeds the tape substrate T from the reel R along the length direction of the tape substrate T; a coating device 20, said coating device 20 applying pressure sensitive adhesive agent (coating agent) S is coated on the tape substrate T fed from the feeding device 10; coating agent S; and a tape rewinding device 40 that rewinds the tape substrate T, wherein the drying of the drying device 30 is completed in the tape substrate T as the reel 400 is rotated. Dry processing. In other words, the drying apparatus 30 according to the present embodiment is utilized as a part of the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com