Telescopic umbrella

a telescopic and umbrella technology, applied in the field of telescopic umbrellas, can solve the problems of inability to extend the telescopic pipe with respect to the upright pipe after opening the umbrella canopy, the tension of the sheathed cable/bowden control is lost, and the position of the telescopic pipe with respect to the upright pipe cannot be changed withou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

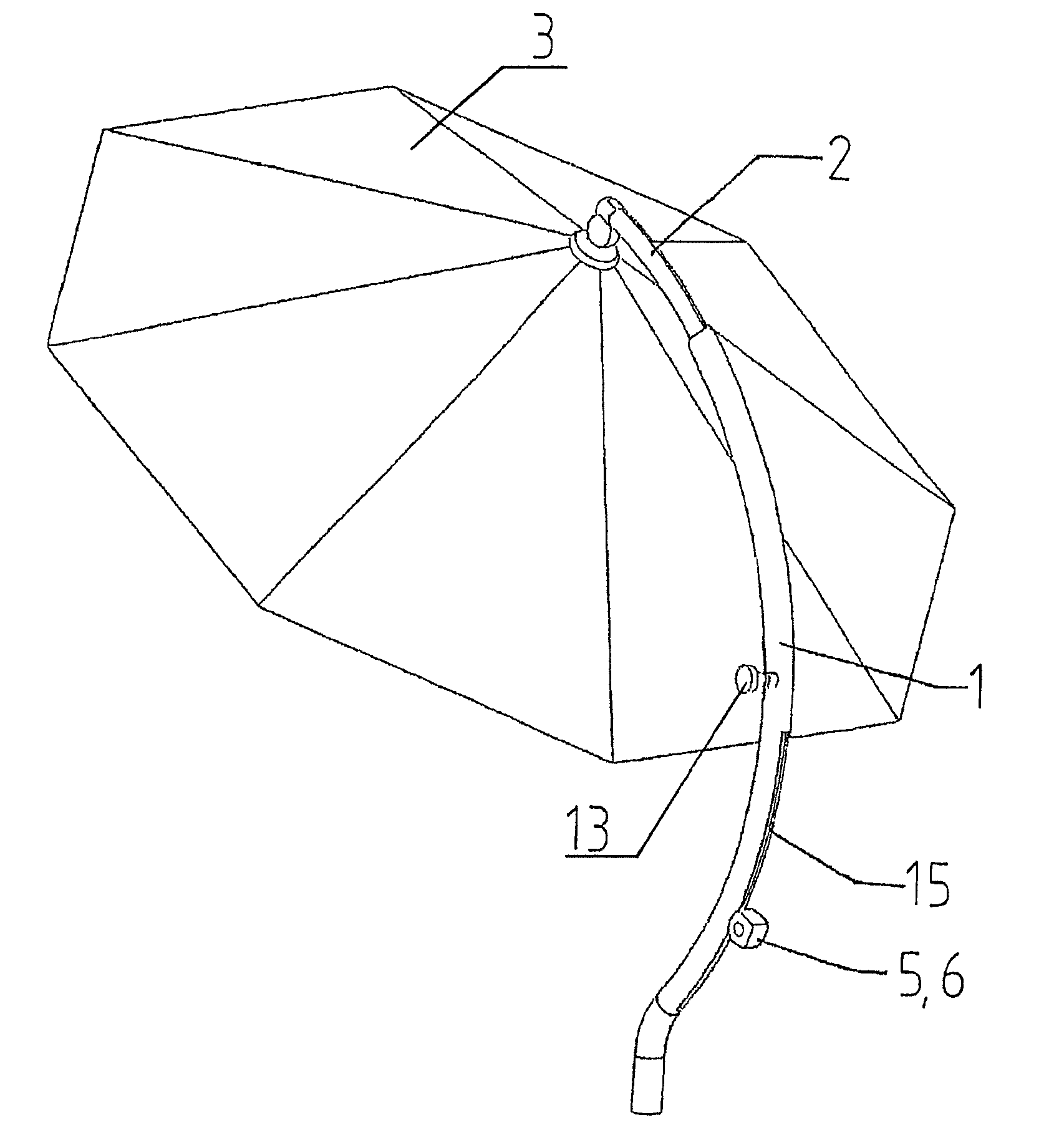

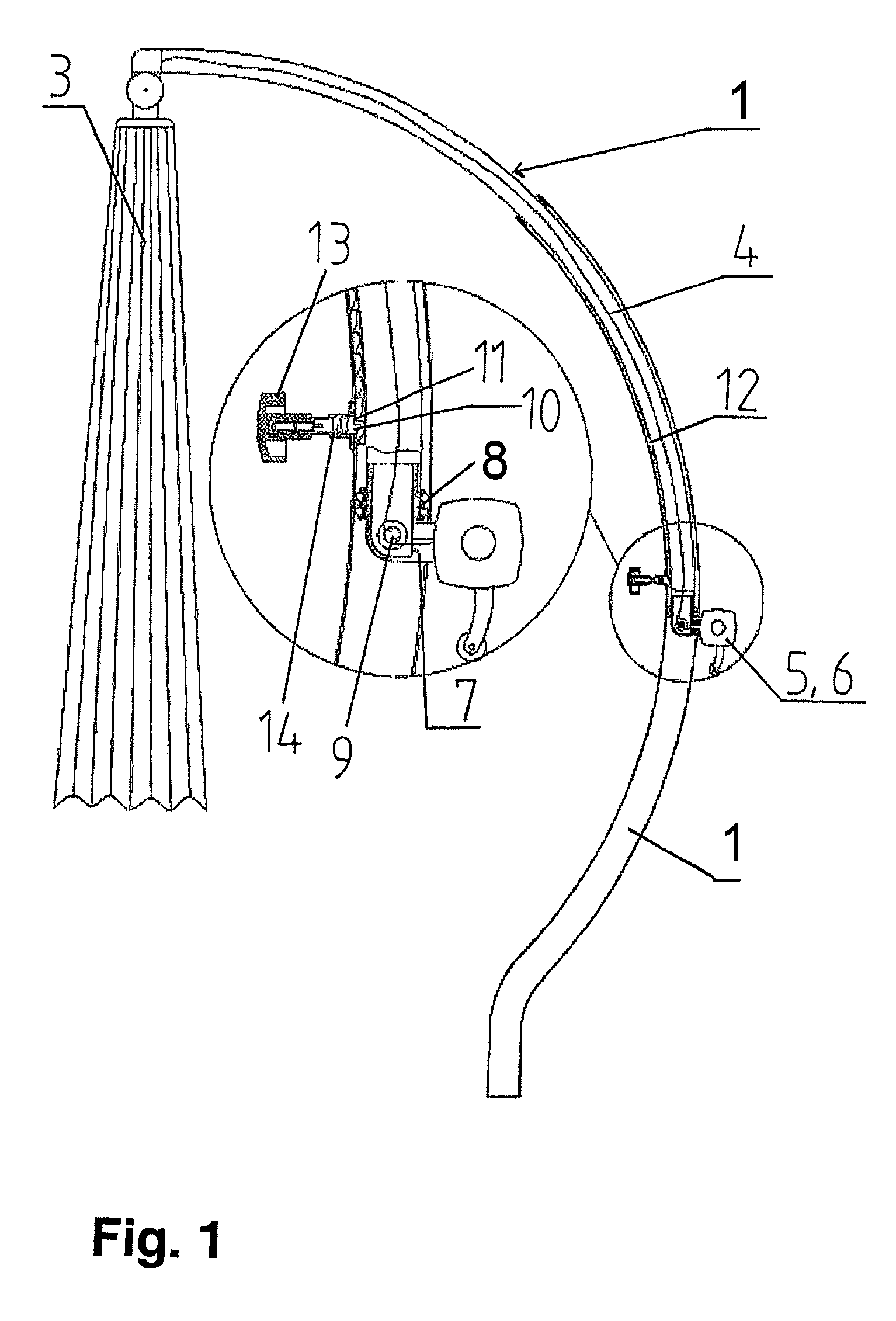

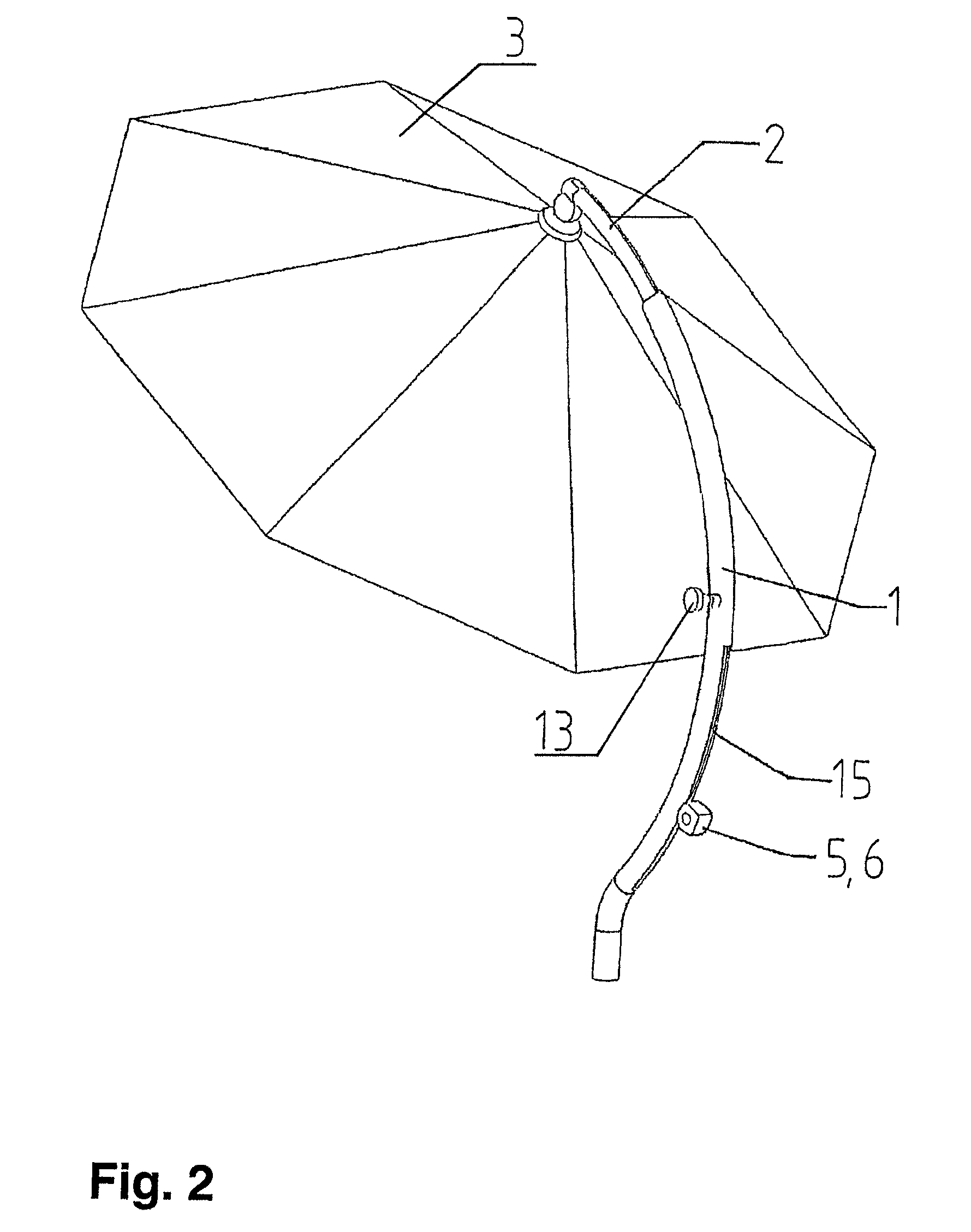

[0037]FIG. 1 shows a partially cut lateral view of a preferred embodiment of the telescopic umbrella according to the invention. The umbrella comprises a lower upright stand pipe 1 and a telescopic pipe 2 which can be moved and locked in the upright stand pipe. An umbrella canopy 3 is joined to the telescopic pipe 2. In this embodiment, both the upright stand pipe 1 as well as the telescopic pipe 2 comprise a curvature, making it possible to suspend the umbrella canopy 3 from the upper end of the telescopic pipe 2. This provides the greatest possible distance between the upright stand pipe or the supporting base from the area shaded by the umbrella canopy 3.

[0038]The umbrella canopy 3 can be opened and closed by means of a sheathed cable / Bowden control 4. For this purpose, the sheathed cable / Bowden control 4 is connected to a control device and can be operated with it. In the embodiment shown, the control device 5 is designed as a crank shaft 6.

[0039]Based on the invention, the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com