Special catalyst drying device with detection function

A drying device and catalyst technology, applied in progressive dryers, drying solid materials, drying, etc., can solve the problems of limited drying function, increased production cost, and low efficiency, and achieve reliable drying effect, fast drying speed, and dry low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

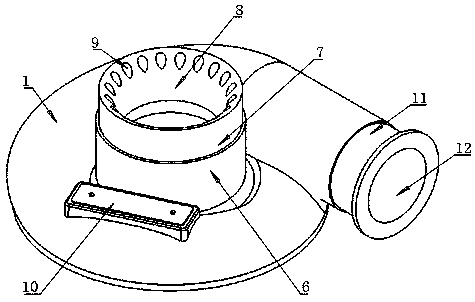

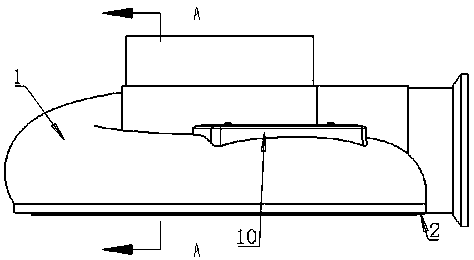

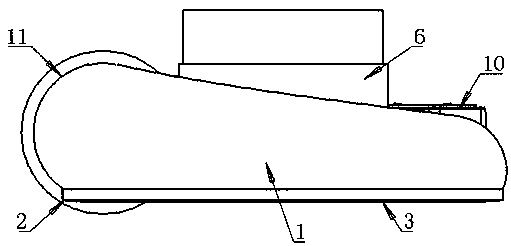

[0019] Such as Figure 1 to Figure 7 As shown, a special catalyst drying device with detection function, which inputs the catalyst to be dried from the upper end of the structure, and sets the cylindrical auxiliary input hole structure uniformly distributed around the main conveying structure to make the catalyst to be dried The dried catalyst can fully contact with the desiccant, so that the catalyst can be thoroughly dried at one time, so that the drying speed of the catalyst is faster and the drying effect is more reliable. It also has a detection equipment placement box on the device, so that it can be better assembled with the catalyst drying detection equipment, so that the drying condition of the catalyst can be grasped at any time during the drying process of the catalyst, so that it can be more convenient during use. It is convenient, and the dried catalyst can be collected in time, which can avoid unnecessary waste of resources caused by over-drying, thereby reducing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com