Apparatus for making window envelopes

a window envelope and window potion technology, applied in envelope/bag making machinery, paper/cardboard containers, paper/cardboard articles, etc., can solve the problems of poor drying characteristics of uv curing type, inferiority in the productivity of window envelopes, and mucking of window potion formed on paper, so as to achieve rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]A suitable form of implementation of the present invention will now be described below with reference to the drawing Figures.

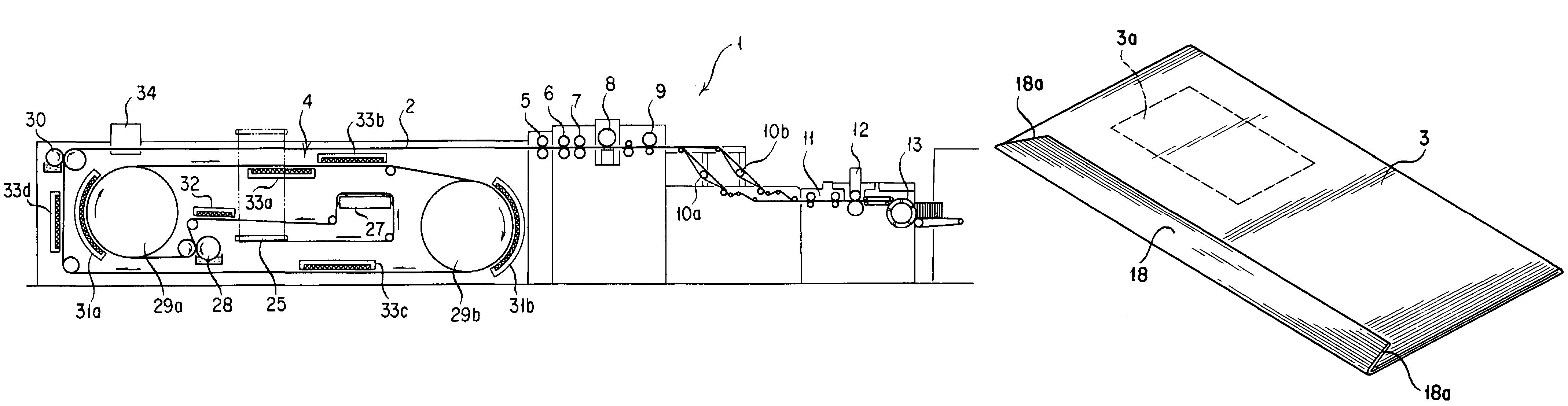

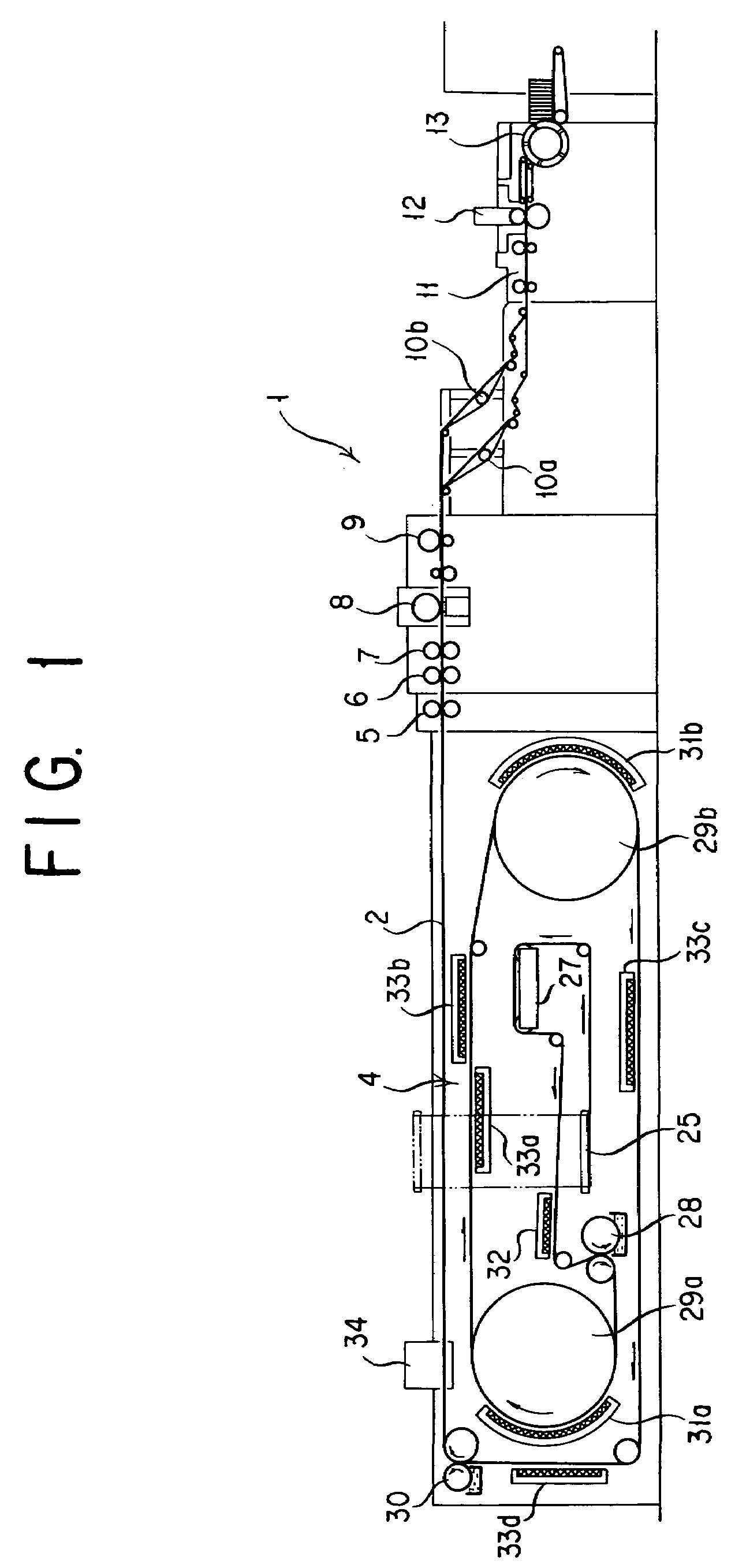

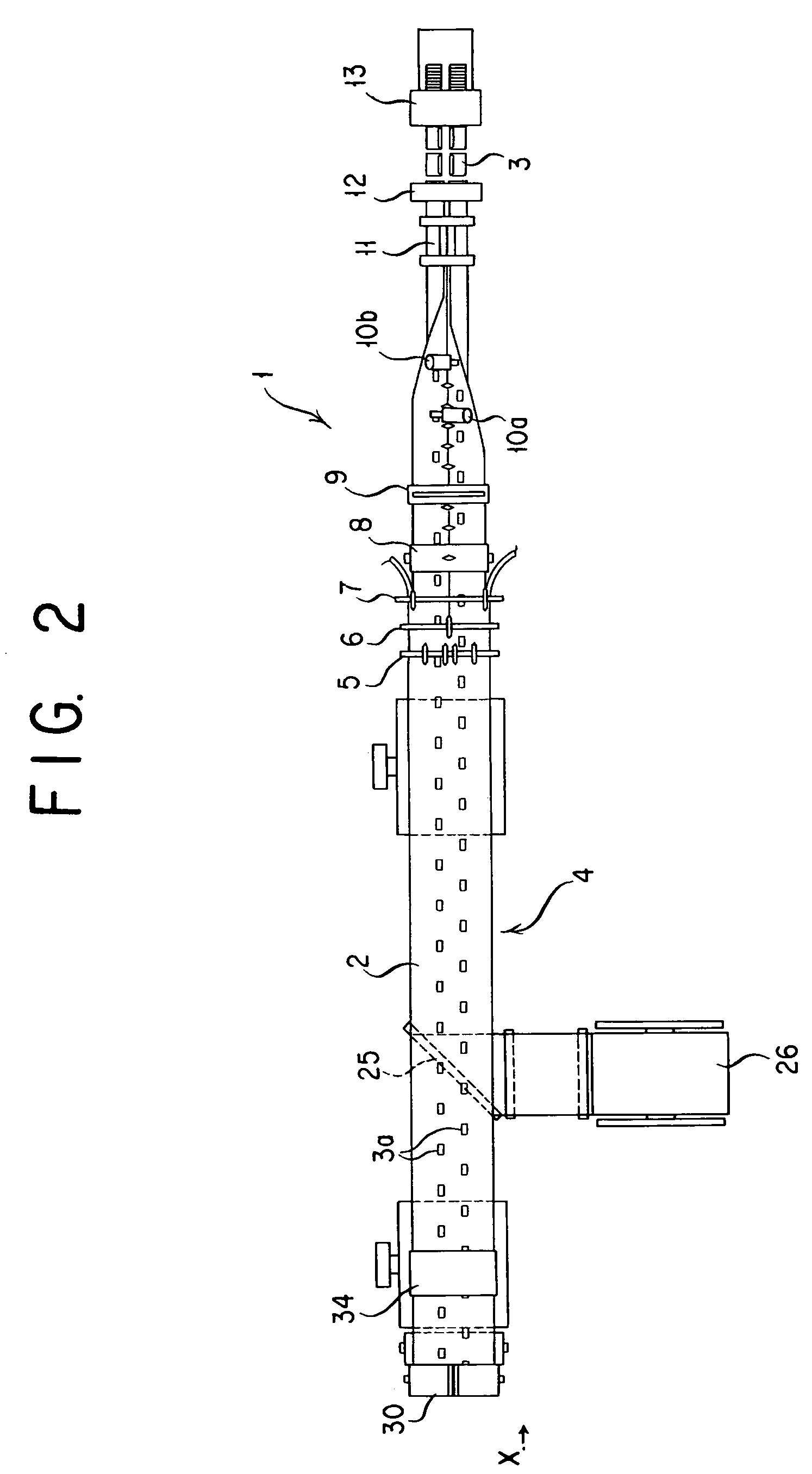

[0024]Referring to FIGS. 1 to 3, there are shown an envelope making unit 1 for making window envelopes 3, each of which is as shown in FIG. 7, from a double-width continuous paper 2 while folding it up; and a clarifying agent applying unit 4 disposed upstream of the envelop making unit 1.

[0025]Included in the envelope making unit 1 and disposed in turn from its upstream side are a creaser 5, a center slitter 6, a double sided slitter 7, a die-cut roll 8, an adhesive applicator 9, a pair of plow folders 10a and 10b, a flap folder 11, a cutter 12 and a carrying out device 13.

[0026]According to this envelope making unit 1, a continuous paper 2 traveling out of the clarifying agent applying unit 4 is first subjected to creasing by the creaser 5 where as shown at A in FIG. 6 fold lines 14 and 14 and flap fold lines 15 and 15 are imparted thereto parallel to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com