Membranization calcium silicate veneer and preparation method thereof

A technology of filming calcium silicate and calcium silicate board, which is applied in the direction of chemical instruments and methods, wood layered products, lamination, etc., can solve the problems of easy foaming of wood fiber fluff and unsatisfactory effect, which is not easy to achieve Damaged, easy to clean, solve the effect of high moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

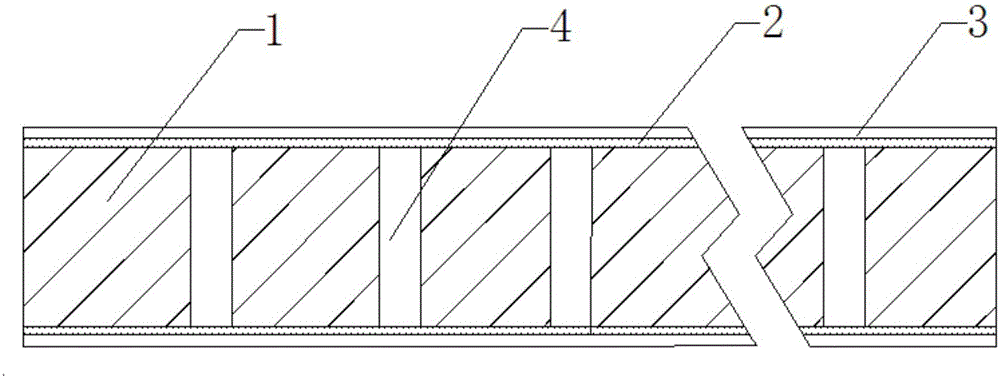

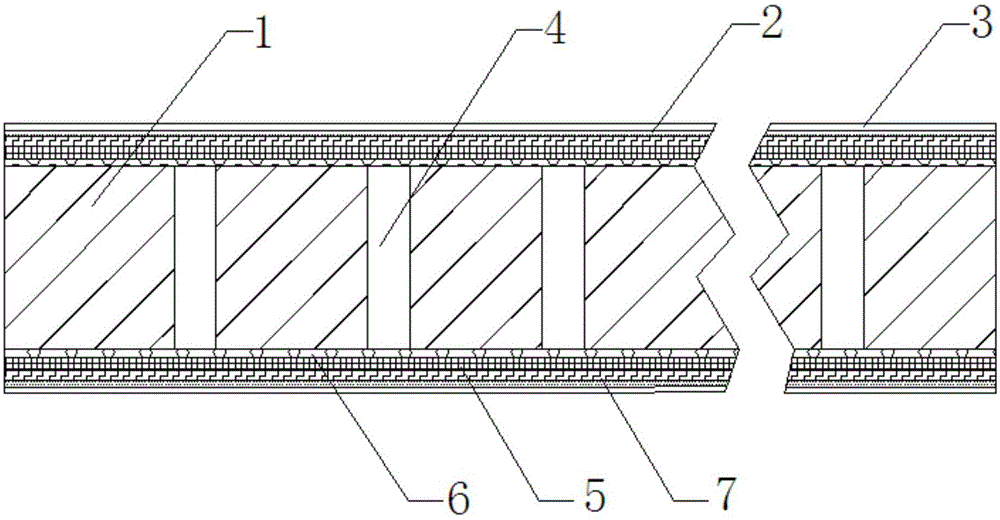

[0039] In order to achieve the purpose of the present invention, the preparation method of filmized calcium silicate veneer of the present invention, described method comprises the following steps:

[0040] 1) Punch air holes on the calcium silicate board;

[0041] 2) smear UV coating on both sides of the calcium silicate board after punching air holes, obtain the calcium silicate board coated with UV coating;

[0042] 3) The PVC polymer film is then pasted on the calcium silicate board coated with UV coating by a pneumatic rolling laminating machine.

[0043] The preparation method of the filmed calcium silicate veneer has a simple film coating process, and tests show that the filmed calcium silicate veneer prepared by film coating with a pneumatic rolling laminating machine has a clean, smooth appearance and is not easy to be damaged.

[0044] In order to further optimize the implementation effect of the present invention, in step 2), after obtaining the calcium silicate bo...

Embodiment 1

[0050] 1) Punch air holes on the calcium silicate board;

[0051] 2) Smear UV coating on both sides of the calcium silicate board after punching air holes to obtain a calcium silicate board coated with UV coating, and then process it through dust removal;

[0052] 3) Then put the PVC polymer film into the dynamic roller press, adjust the rolling temperature to 80°C, and the pressure to 8.0MPa, put the calcium silicate board coated with UV coating into the roller press, and start the pneumatic roller press The machine completes the attachment of the PVC polymer film, and finally puts the filmized calcium silicate veneer that has been attached to the PVC polymer film into a microwave dryer, and dries at 45 °C; then trims the edge, and it is ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com