Cleaning machine drying method and cleaning machine applying same

A cleaning machine and fan technology, applied in the field of cleaning machines, can solve problems such as inability to adapt to temperature changes of heating elements, prolonged drying time, and failure of effective remediation of heating elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

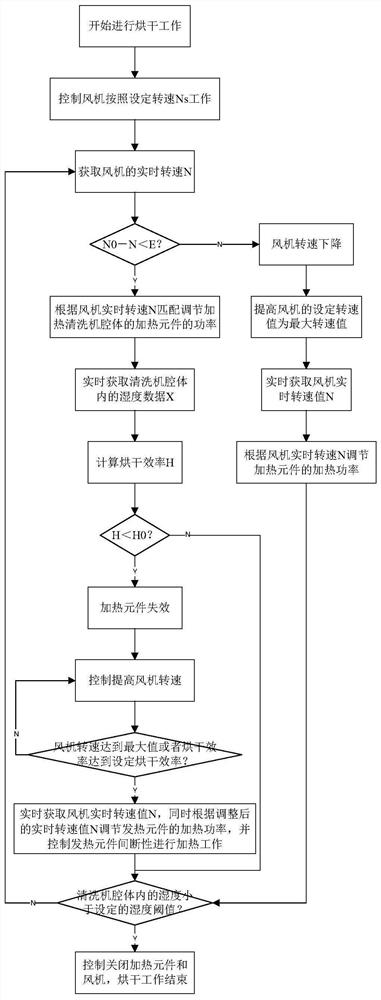

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 As shown, the washing machine drying method in this embodiment is implemented by a washing machine with a drying system. The cleaning machine in this embodiment includes a body and a drying system arranged in the body, wherein the drying system includes a control circuit board, a humidity sensor for detecting the humidity in the cleaning machine cavity, and a fan for blowing air into the cleaning machine cavity 1. The heating element arranged at the front end of the fan, the humidity sensor, the fan, and the heating element are respectively connected to the control circuit board for electrical signals. circuit.

[0024] Wherein the heating element can adopt various heaters in the prior art, and the heating element in this embodiment adopts a PTC heating element. The speed regulation circuit on the control circuit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com