Color master batch drying device

A drying device and color masterbatch technology, applied in the field of color masterbatch processing, can solve the problems of excessive moisture, insufficient drying, uneven moisture content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The content of the present invention will be described below in conjunction with specific embodiments.

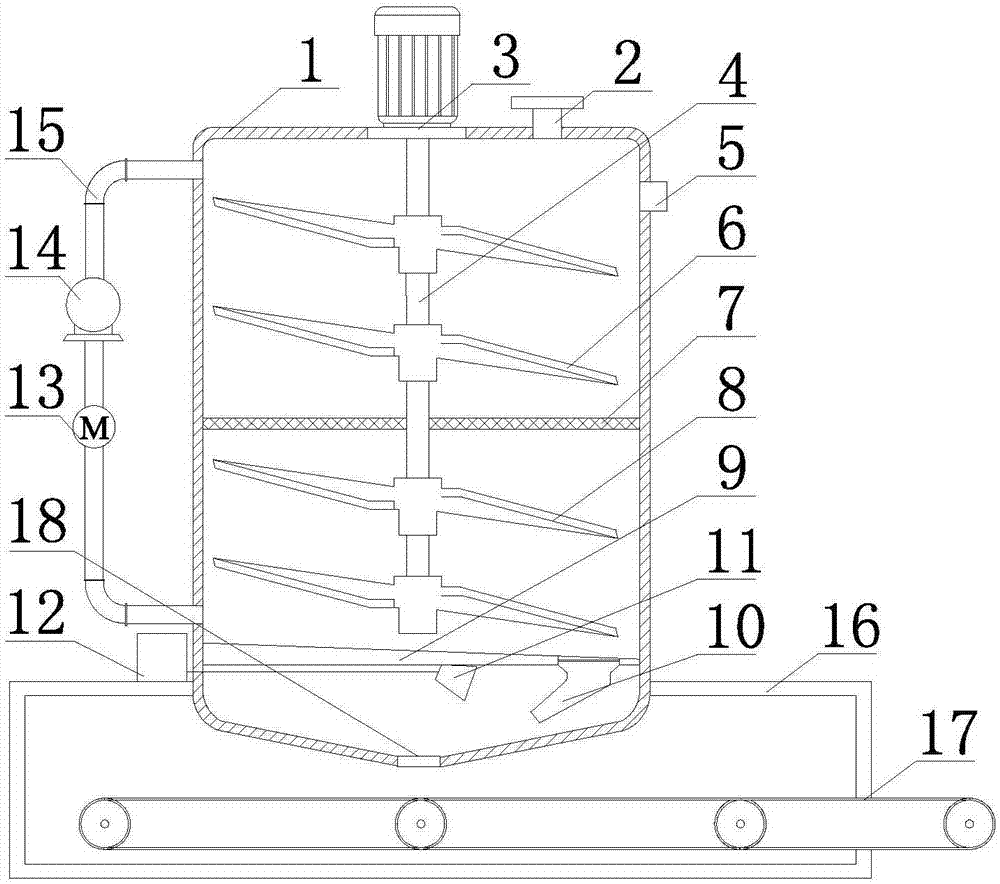

[0014] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a color masterbatch drying device proposed by the present invention.

[0015] A kind of masterbatch drying device proposed by the present invention comprises a bracket 16 and a drying box 1 connected to the bracket 16, and the drying box 1 is provided with a filter screen 7 and a material blocking plate 9 sequentially from top to bottom. The filter screen 7 and the baffle plate 9 separate the drying box 1 from top to bottom into an upper drying chamber, a middle drying chamber and a lower drying chamber. The upper drying chamber or the middle drying chamber is connected with a vent, and the drying The top of the case 1 is provided with a motor 3, the output shaft of the motor 3 is driven and connected to a main shaft 4, the main shaft 4 is vertically arranged, and one end of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com