Coal-fired boiler facilities and coal drying method in coal-fired boiler facilities

A technology for coal-fired boilers and coal drying, applied in combustion equipment, combustion methods, lighting and heating equipment, etc., can solve problems such as mixing in and impact on the performance of waste gas treatment equipment, to improve efficiency, suppress efficiency reduction, and suppress hydrocarbon components the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

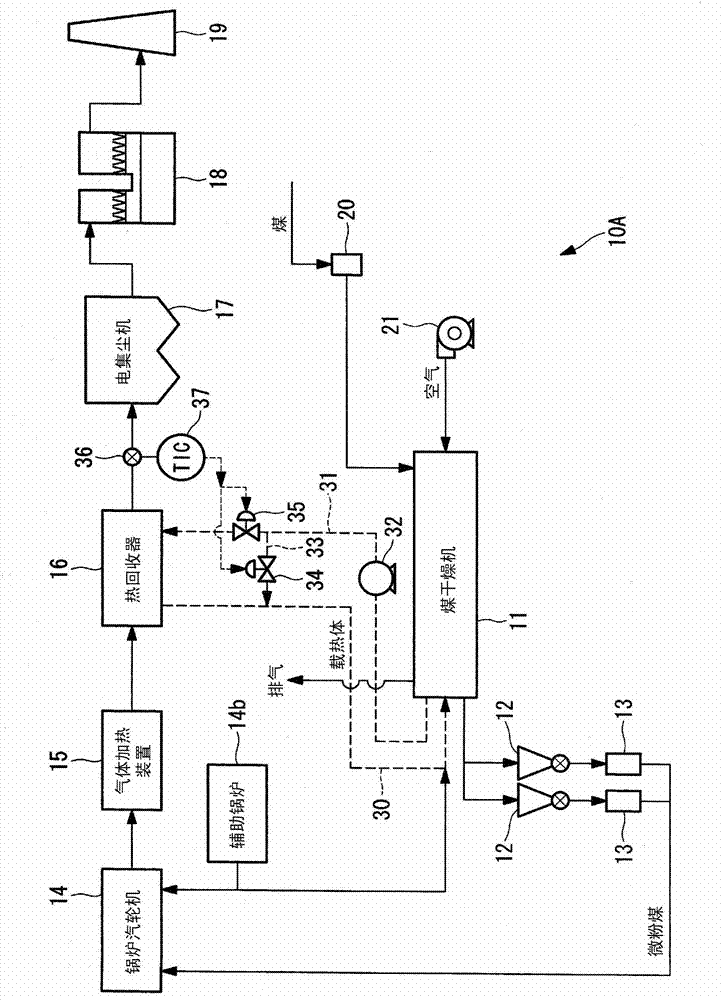

[0051] Below, use figure 1 A first embodiment of the present invention will be described.

[0052] Such as figure 1 As shown, the coal-fired boiler equipment 10A mainly includes a coal dryer 11, a coal hopper 12, a coal mill 13, a boiler steam turbine (boiler) 14, a gas heating device 15, a heat recovery device 16, an electric dust collector 17, and a desulfurization device 18 and chimney 19.

[0053]The coal pulverized by the coal pulverizer 20 is fed into the coal dryer 11, and the coal dryer 11 dries the coal by a structure described in detail later while conveying the coal using air fed by the blower 21 as a transport gas.

[0054] The coal hopper 12 temporarily stores the coal dried by the coal dryer 11 .

[0055] The coal mill 13 pulverizes the coal supplied from the coal hopper 12 to form pulverized coal of a predetermined particle size.

[0056] The pulverized coal pulverized by the coal mill 13 is sent to the boiler turbine 14, where it is mixed with combustion ai...

no. 2 approach

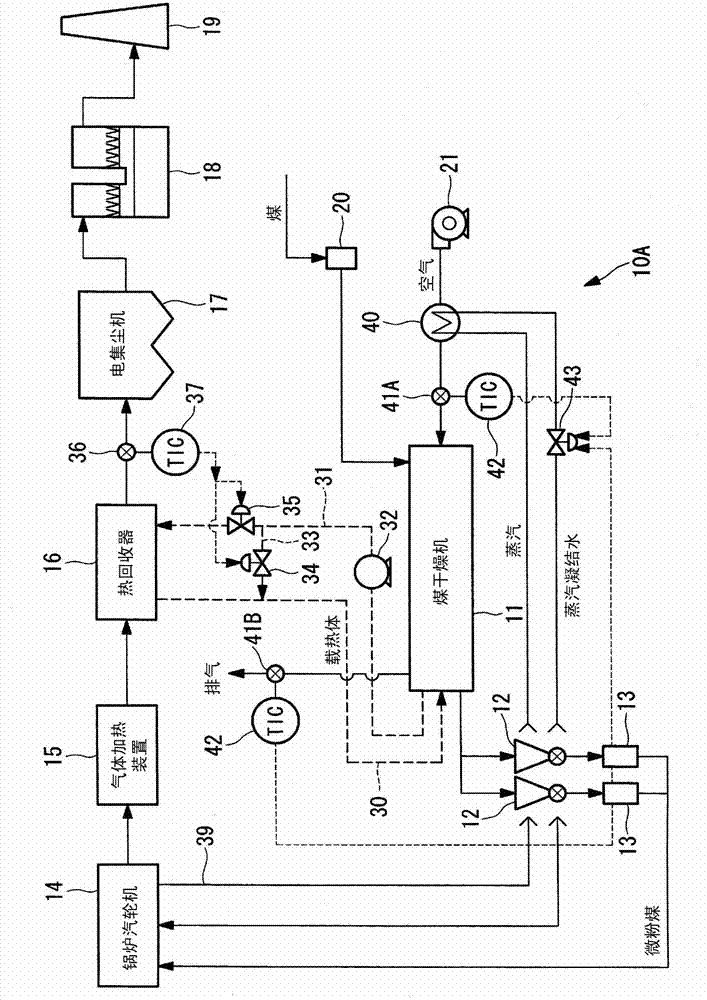

[0093] Next, a second embodiment of the present invention will be described. In the second embodiment described below, the same reference numerals are assigned to the same configurations as those of the first embodiment in the drawings, and their descriptions are omitted, and differences from the first embodiment are mainly described. illustrate.

[0094] Such as Figure 5 As shown, the coal-fired boiler equipment 10B of this embodiment mainly includes a coal dryer 11, a coal hopper 12, a coal mill 13, a boiler steam turbine 14, a gas heating device 15, a heat recovery device 16, an electric dust collector 17, and a desulfurization device 18 and chimney 19.

[0095] In this embodiment, the coal pulverized by the coal pulverizer 20 is fed into the coal dryer 11, and the coal dryer 11 uses the second gas heating device 60 to heat the air sent from the blower 21 as heating air. The heated air is used as transport gas to transport the coal, and the heat of the heated air dries ...

no. 3 approach

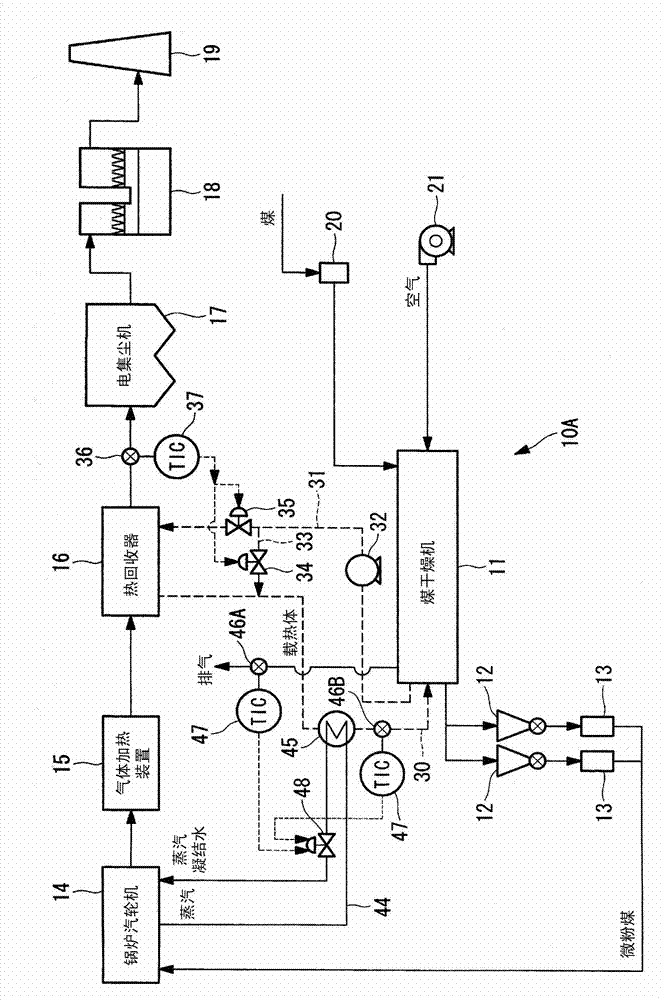

[0117] Next, a third embodiment of the present invention will be described. In the third embodiment described below, the same reference numerals are assigned to the same configurations as those of the first and second embodiments in the drawings, and their descriptions are omitted. Differences of the embodiments will be described.

[0118] The structure of the third embodiment shown below can also be added to Figure 1 to Figure 8 Either structure shown. Below, shown in Figure 5 An example of the structure of this embodiment is added to the shown structure.

[0119] Such as Figure 9 As shown, the coal-fired boiler equipment 10C of this embodiment is in Figure 5 The shown coal-fired boiler facility 10B further includes a gypsum separator 65 and a spray dryer 66 in addition to the configuration.

[0120] The gypsum separator 65 filters the wastewater from the desulfurization device 18 and separates it into a gypsum component and a filtrate. The filtrate (drainage) obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com