Device and method for drying a treated product

An article, drying technology, applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve the problems of deflection or bending, ineffective drying, prolonged drying time, etc., to achieve the effect of gentle drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

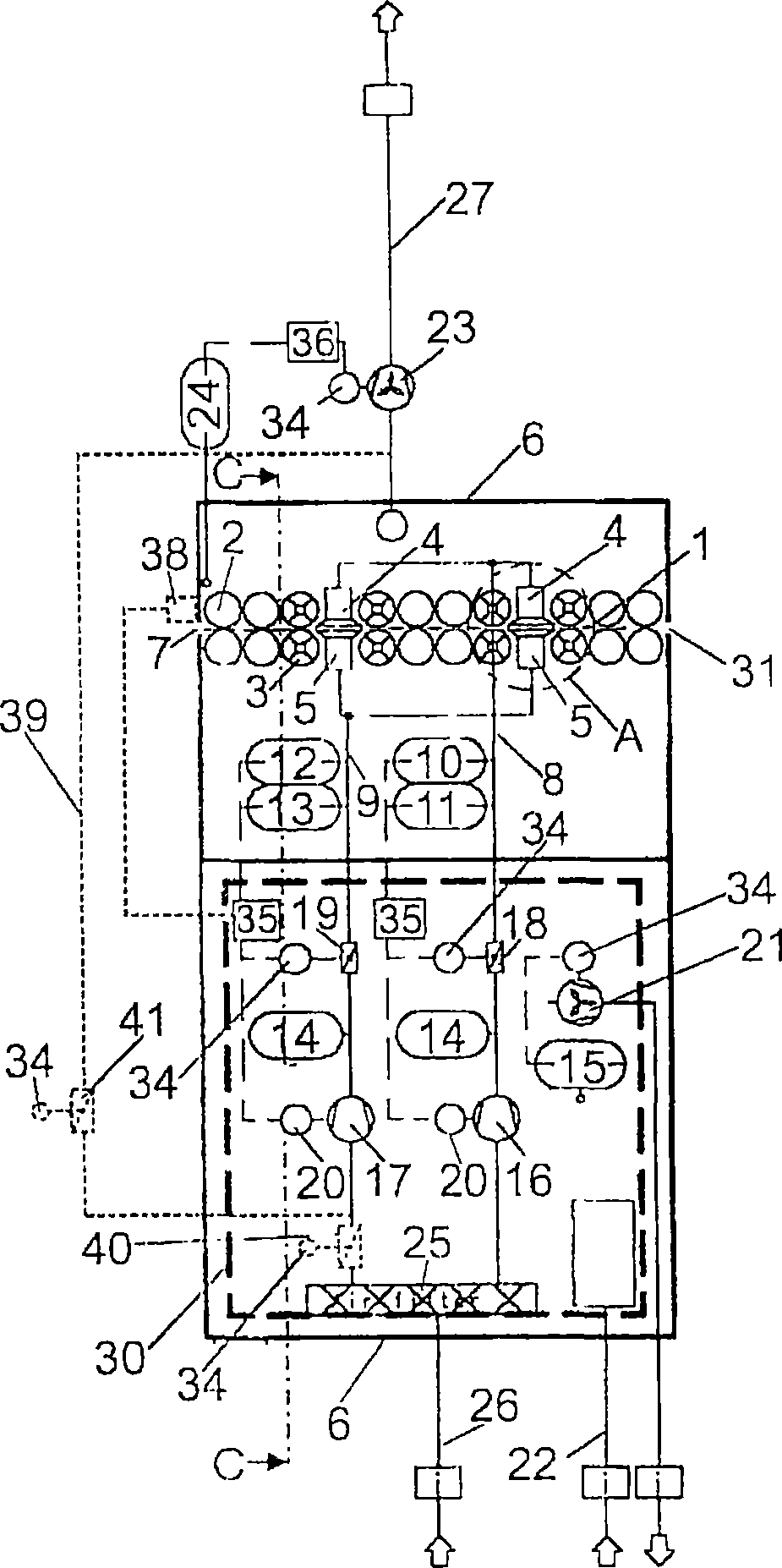

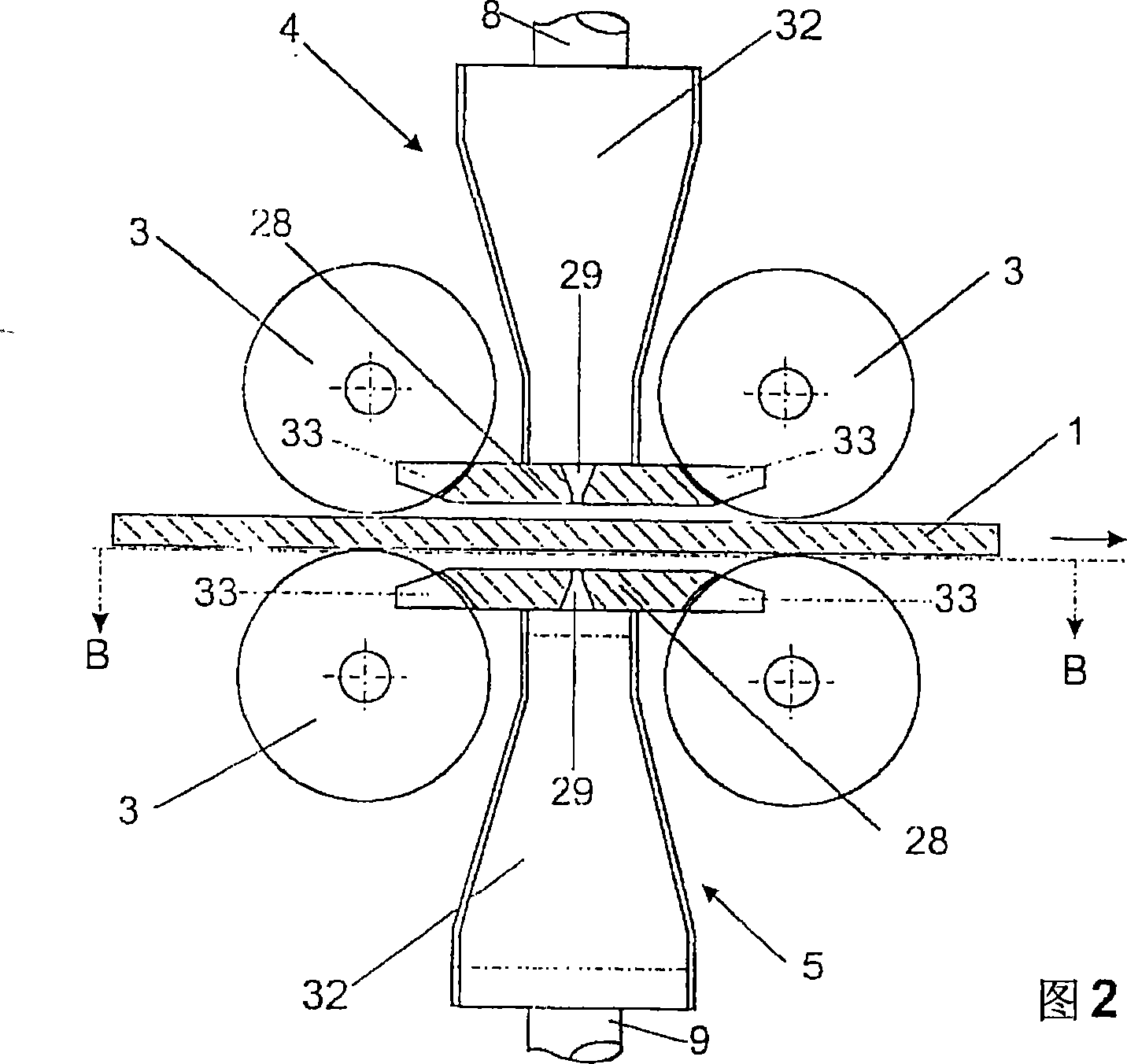

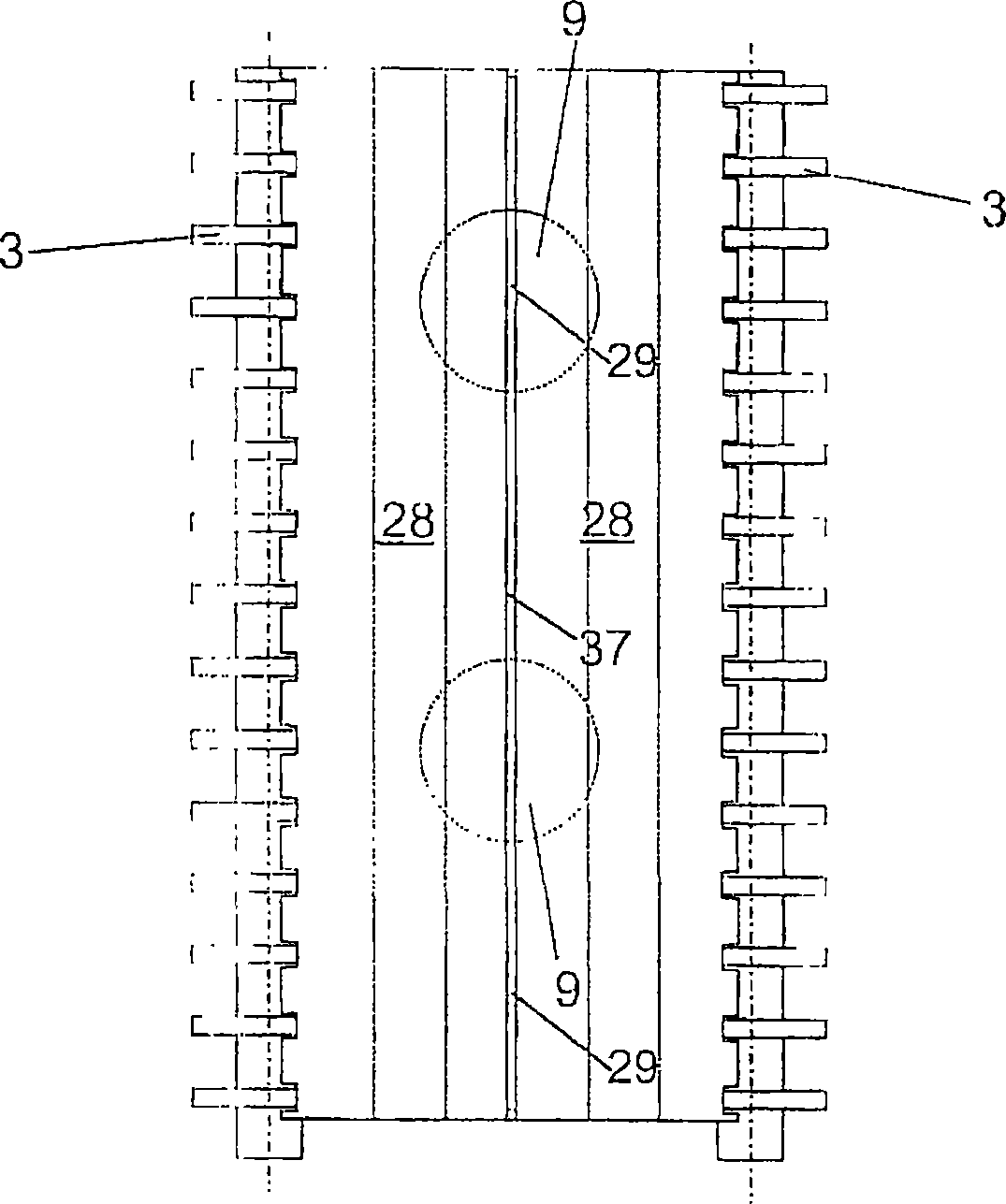

[0030] figure 1 The structure and interaction of the different parts of the dryer according to the invention are schematically shown. The dryer comprises a housing 6 divided into two parts, compressed air fans 16, 17 arranged in the lower part of the housing 6, which independently supply compressed air to nozzles 4 and 5 called pressure nozzles, The compressed air is used as drying medium in this case. The nozzles 4 and 5 are located in the upper part of the housing 6 . The nozzle 4 is arranged above the conveying path extending from the inlet 7 of the housing 6 towards the outlet 31 , while the nozzle 5 is arranged below the conveying path. In each case, nozzle 4 and nozzle 5 are placed opposite each other with their outlet openings facing each other. Two pairs of nozzles 4, 5 are shown in this embodiment; however, there may be more pairs or only one pair of nozzles.

[0031] Located in the lower part of the housing 6 are regulating means 18 and 19 , for example flappers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com