Method of manufacturing electronic device and composite film

a technology of which is applied in the field of manufacturing electronic devices and composite films, can solve the problems of electronic devices that are not suitable for use, electronic devices that are occasionally deteriorated, and the drying of pressure sensitive adhesive layers cannot be properly performed, so as to achieve stable manufacturing of high-quality electronic devices, prevent foreign matter adhesion, and easy and reliably dry pressure sensitive adhesive layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

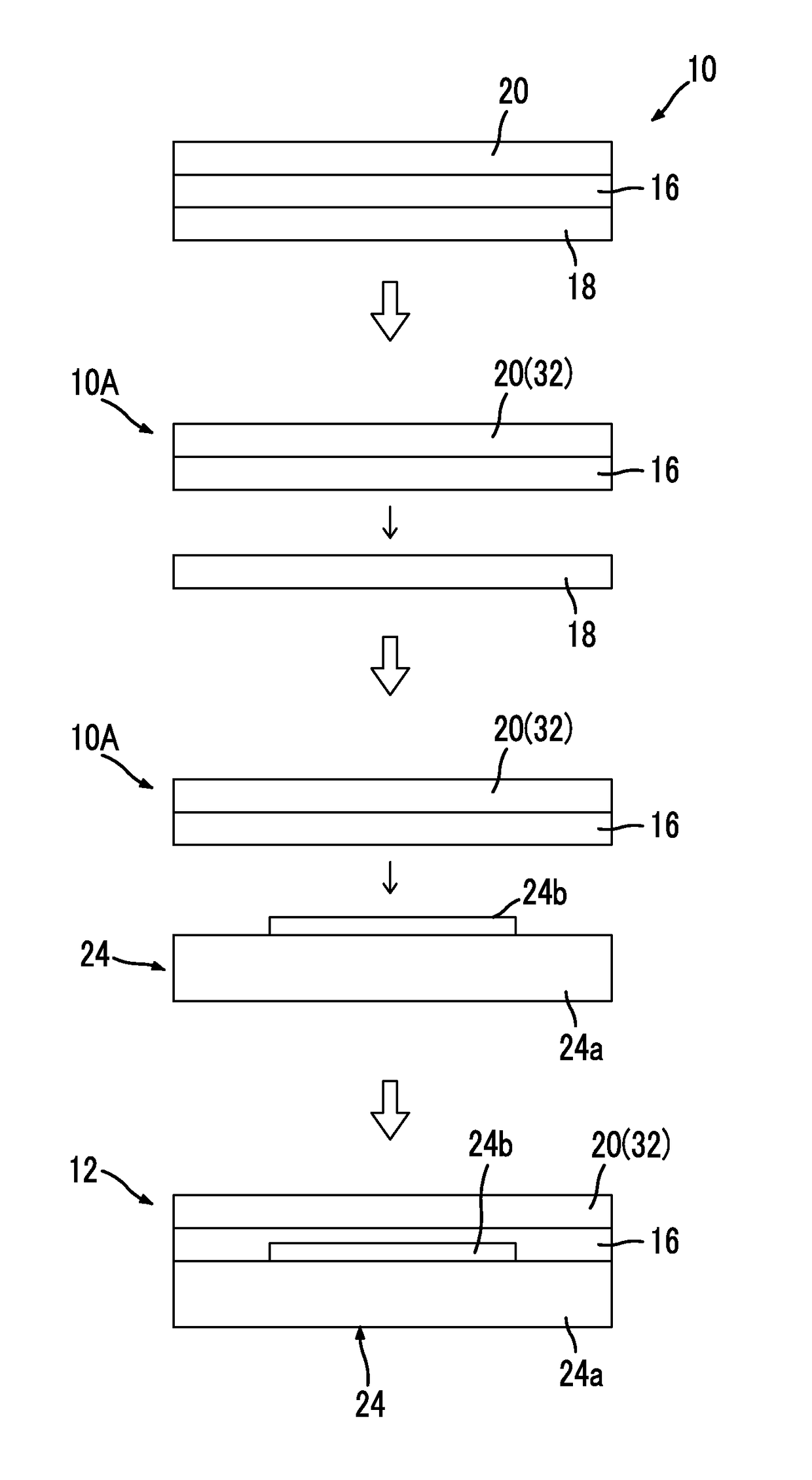

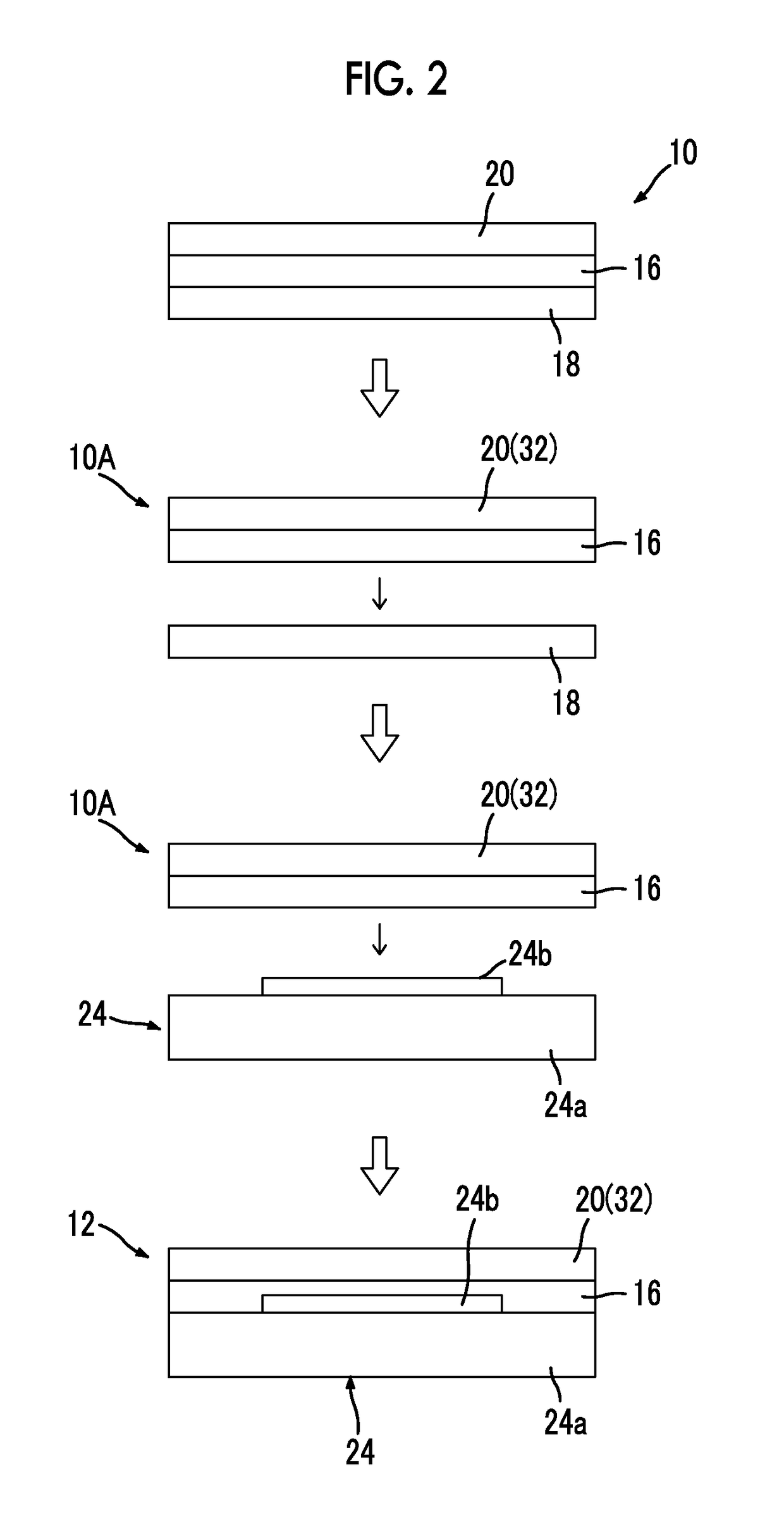

[0145]As the first film 18 and the second film 20, a film obtained by forming a PDMS film having a thickness of 5 μm on the surface of a TAC film having a thickness of 40 μm as a peeling layer was prepared respectively.

[0146]The moisture vapor transmission rate of the first film 18 which was measured in conformity with JIS Z 0208-1976 was 2050 g / (m2·day).

[0147]The peeling layer of the first film 18 was coated with a liquid resin (SK DYNE 1831, manufactured by Soken Chemical & Engineering Co., Ltd.) of two-liquid thermosetting type acrylic ester. The liquid resin was applied using an applicator.

[0148]Next, the peeling layer was directed toward the liquid resin, the second film 20 was laminated, and the liquid resin was cured at 80° C. for 30 minutes, thereby preparing the composite film 10 obtained by bonding the first film 18 and the second film 20 to the pressure sensitive adhesive layer 16 having a thickness of 20 μm.

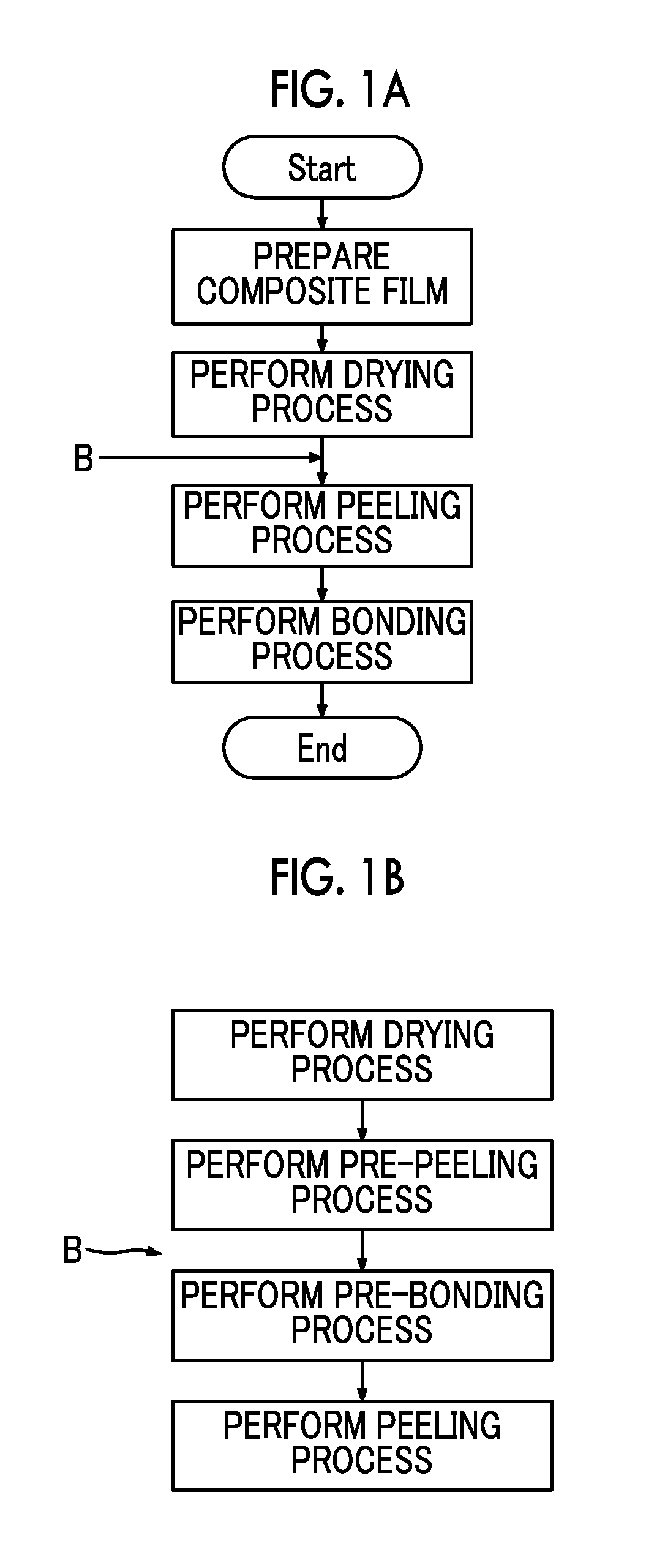

[0149]The composite film 10 was put into a glove box in which th...

example 2

[0153]The composite film 10 was prepared in the same manner as in Example 1 except that the gas barrier layer 30 was directed toward the pressure sensitive adhesive layer 16 and the gas barrier film 26 was bonded to the pressure sensitive adhesive layer 16 using the gas barrier film 26 prepared in advance as the second film 20.

[0154]The composite film 10 was put into a glove box in which the dew point was adjusted to −60° C. Further, all the subsequent processes were performed in the glove box in which the dew point was adjusted to −60° C.

[0155]The composite film 10 which was put into the glove box was subjected to a heat treatment in the same manner as in Example 1 and then the pressure sensitive adhesive layer 16 was dried.

[0156]The composite film 10 was cooled to room temperature and then the first film 18 was peeled. Next, the composite film 10A from which the first film 18 was peeled was bonded to the organic EL device body 24 prepared in advance, and then the organic EL device...

example 3

[0157]The organic EL device 12 was prepared in the same manner as in Example 1 except that the second film 20 of the composite film 10 was made into a film obtained by forming a film of an ethylene-vinyl acetate (EVA) copolymer having a thickness of 5 μm on the surface of a PET film having a thickness of 50 m as a peeling layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com