Boiling type material drying method and special boiling kettle thereof

A drying method and boiling technology, which is applied in the directions of drying solid materials, heating to dry solid materials, drying, etc., can solve the problem that the internal space utilization rate of the drying drum is not high, which affects the improvement of the productivity of the drying operation, and the fluidized bed system The space utilization rate is not high, and the effect of reducing the difficulty of control and invalid internal friction, reliable drying operation and convenient control process is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

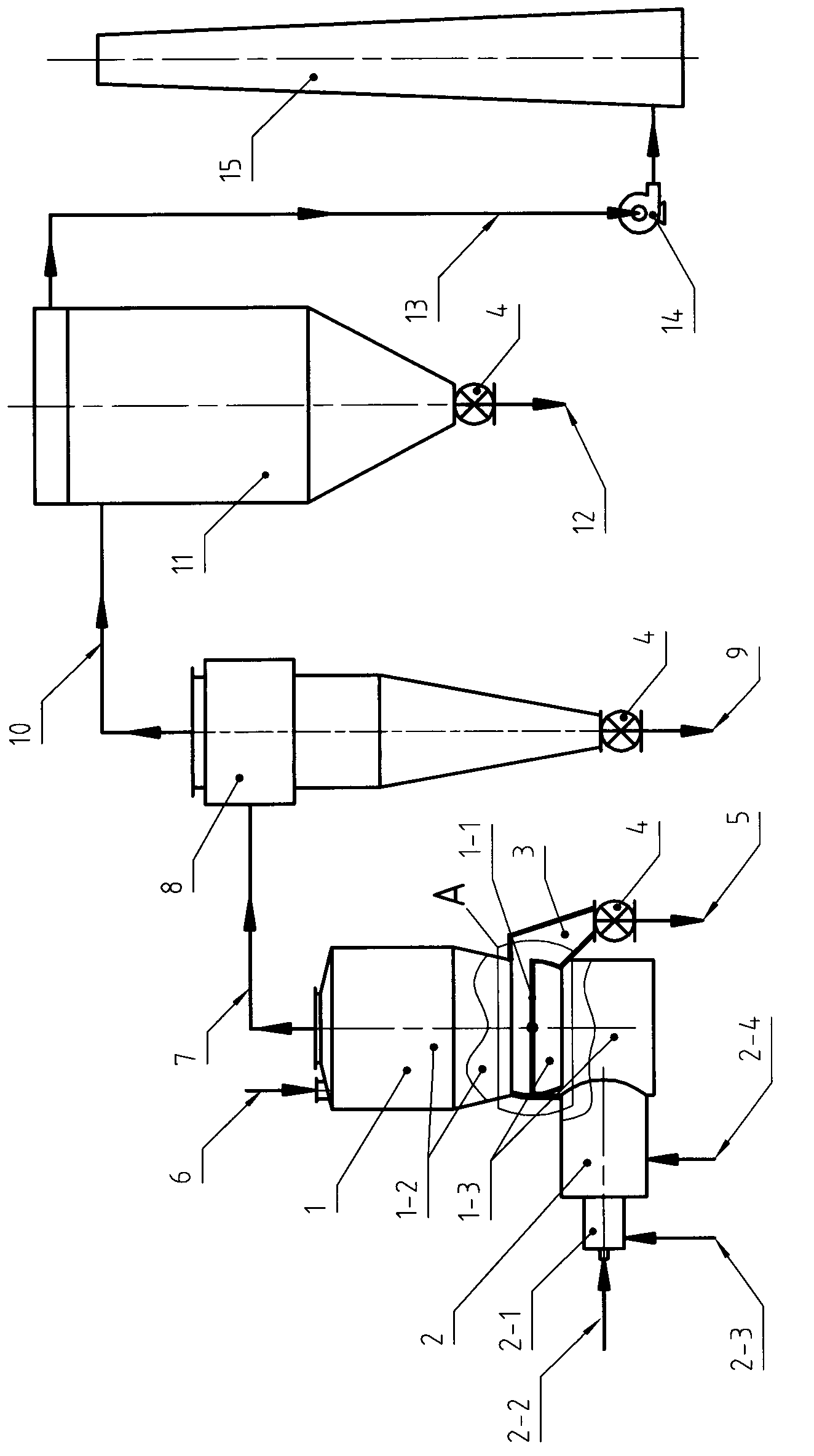

[0051] Example 1, such as figure 1 with Figure 4 shown.

[0052] exist figure 1 Among them, 1 means boiling furnace; it is divided into material boiling or vigorous tumbling section 1-2 and air inlet equalizing section 1-3 by orifice plate 1-1. 2 means flue gas furnace, which includes combustion chamber 2-1, fuel The inlet channel 2-2, the combustion-supporting gas channel 2-3 and the temperature-adjusting mixed gas channel 2-4; the flue gas furnace 2 and the fluidized fluidized furnace 1 have an integrated structure to reduce heat loss and pressure loss of the pipeline; the flue gas furnace The air outlet of 2 and the air inlet of fluidized fluidized furnace 1 have the shape of combining two into one, so that the hot air generated by the flue gas furnace directly enters the air inlet and pressure equalization section 1-3. 3 is the discharge port of fluidized fluidized furnace 1, which is set on the material The lower part of the boiling or vigorous tumbling section 1-2. ...

Embodiment 2

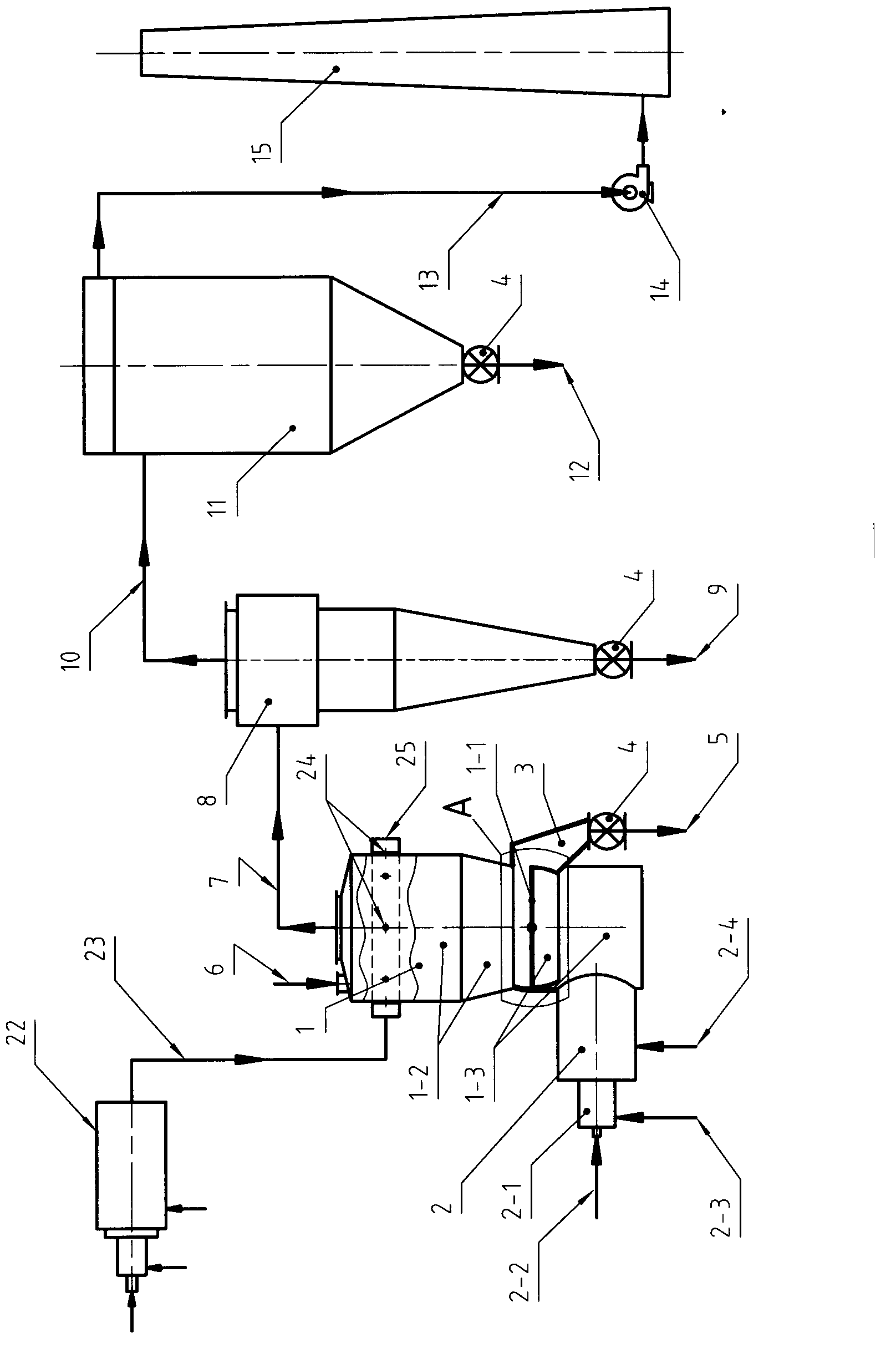

[0058] Example 2, such as figure 2 shown.

[0059] This embodiment has carried out some changes on the basis of embodiment 1:

[0060] 1. The second flue gas furnace 22 and its hot flue gas delivery channel 23 are added; here it needs to be added that although the function of the second flue gas furnace 22 to supply hot air can be replaced by the split flow of the flue gas furnace 2, but , In order to improve the controllability of the hot air flow, the measure of setting the second flue gas furnace 22 is taken.

[0061] 2. The inlet 24 of the secondary hot air is set from the middle or above the middle part of the material boiling or violent tumbling section of the boiling kettle, and the hot air from the second flue gas furnace 22 is passed through the secondary hot air by using the annular passage 25 The inlet 24 is sent to the boiling kettle to strengthen the drying capacity of the system, especially to prevent condensation at the receiver, especially the second receive...

Embodiment 3

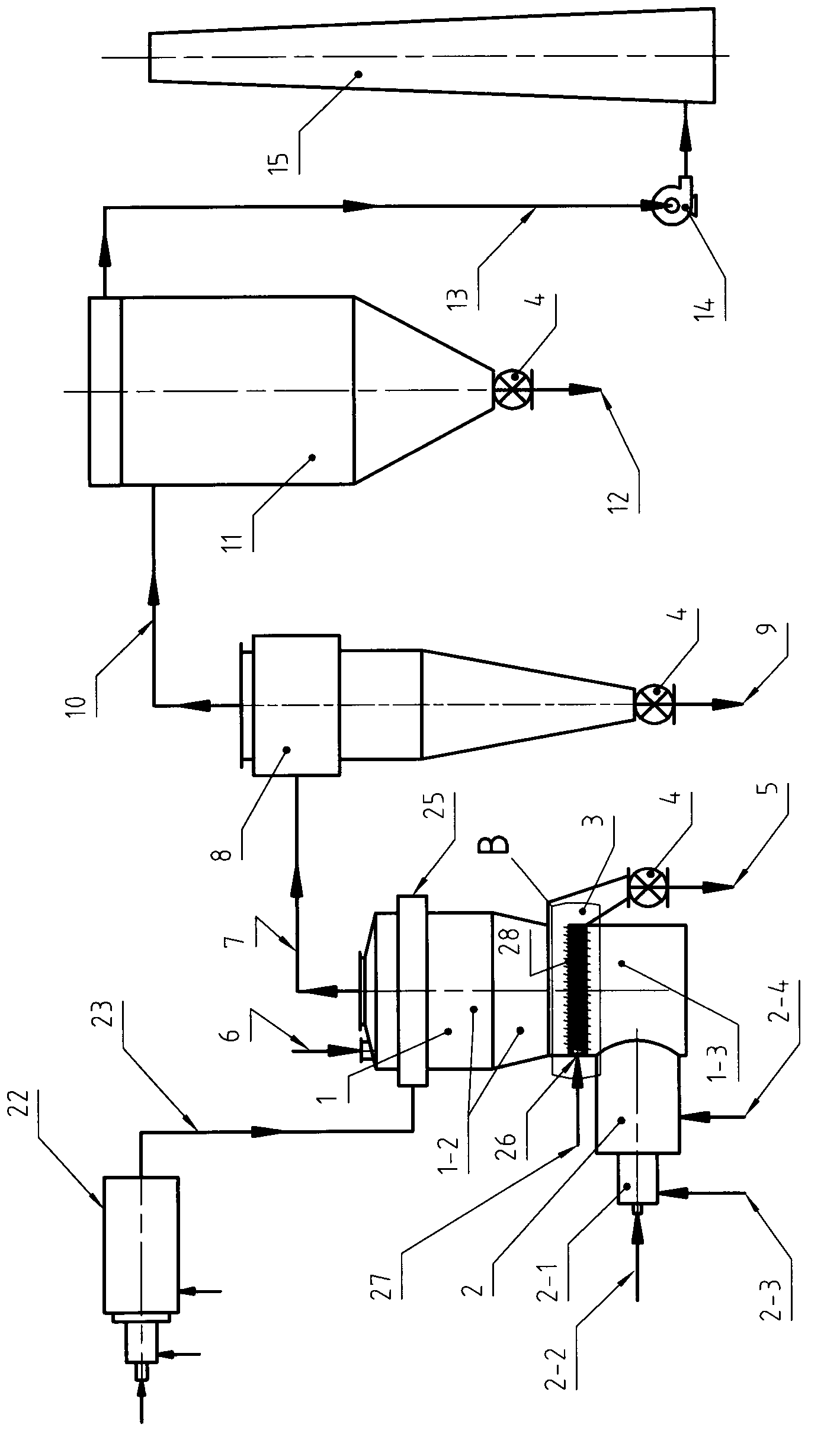

[0063] Example 3, such as image 3 with Figure 5 shown.

[0064] This embodiment has carried out some changes on the basis of embodiment 2:

[0065] 1. The powerful blast port 26 and the powerful blast channel 27 are added;

[0066] 2. With embodiment 2 ( figure 1 or figure 2) in the orifice plate 1-1 is changed to the orifice plate 28 in this embodiment. pass image 3 with Figure 5 , especially through Figure 5 , it can be seen that: the orifice plate 28 has a sandwich structure, and forms a cavity 29 between its upper and lower plates; the orifice plate 28 is shaped on two kinds of holes: the hole 30 and the hole 31, and the hole 30 only controls the boiling of the material Or the violent tumbling section 1-2 is connected with the air inlet equalizing section 1-3, and the hole 31 only connects the boiling or violent tumbling section 1-2 of the material with the cavity 29; , so, the wind that enters from the powerful blast port 26 will directly enter the section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com