Replaceable prestressed anchor bolt device and mounting and replacement construction method thereof

A prestressing and anchoring technology, applied in the field of replaceable prestressing anchoring devices, can solve the problems of difficult construction, hidden safety hazards, high cost of tunnel digging, etc., and achieves high work efficiency, low replacement cost, and saving manpower and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

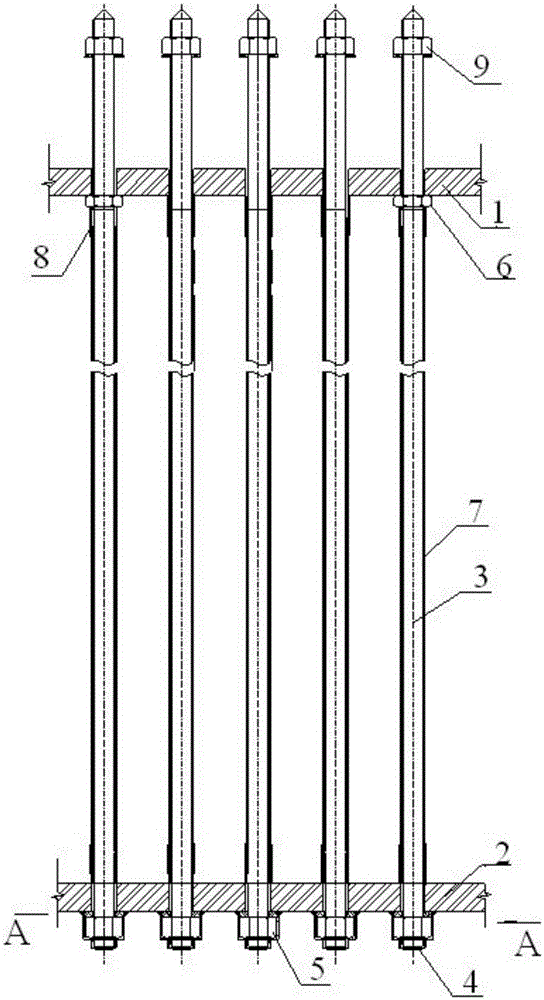

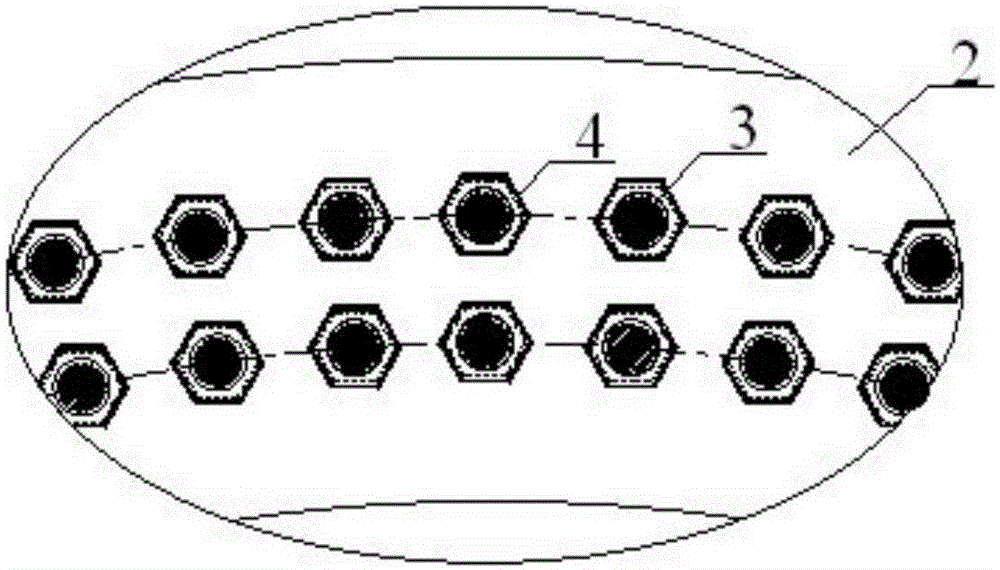

[0036] Such as figure 1 , figure 2 and image 3 As shown, a device for replaceable anchor bolts, which includes an upper anchor plate 1, a lower anchor plate 2, an anchor bolt 3 connecting the upper anchor plate 1 and the lower anchor plate 2, between the upper anchor plate 1 and the lower anchor plate 2 The outer periphery of the anchor bolt 3 is covered with a plastic sleeve 7, and the upper and lower ends of the plastic sleeve 7 are shrunk and sealed by a heat shrinkable sleeve 8, and a non-metallic leveling nut 6 is installed on the heat shrinkable sleeve 8 at the upper end of the plastic sleeve 7. An upper nut 9 is installed on the top of the anchor bolt 3; the bottom of the anchor bolt 3 is fixed with the bottom sealing assembly 4.

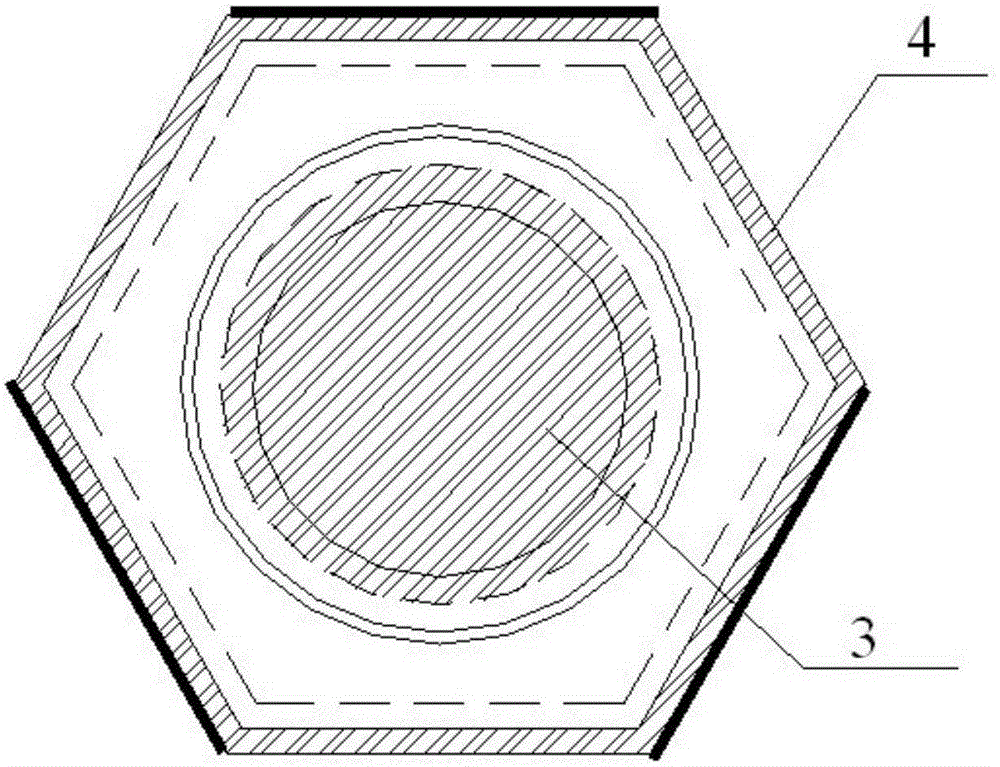

[0037] The outside of the bottom seal assembly 4 is in a hexagonal shape, and the inside is a threaded structure adapted to the bottom of the anchor bolt 3 .

[0038] In the replaceable prestressed anchor bolt assembly described above, t...

Embodiment 2

[0040] Such as figure 1 , figure 2 and Figure 4 As shown, a device for replaceable anchor bolts, which includes an upper anchor plate 1, a lower anchor plate 2, an anchor bolt 3 connecting the upper anchor plate 1 and the lower anchor plate 2, between the upper anchor plate 1 and the lower anchor plate 2 The outer periphery of the anchor bolt 3 is covered with a plastic sleeve 7, and the upper and lower ends of the plastic sleeve 7 are shrunk and sealed by a heat shrinkable sleeve 8, and a non-metallic leveling nut 6 is installed on the heat shrinkable sleeve 8 at the upper end of the plastic sleeve 7. An upper nut 9 is installed on the top of the anchor bolt 3; the bottom of the anchor bolt 3 is fixed with the bottom sealing assembly 4.

[0041] The bottom seal assembly 4 is circular in shape on the outside, and has a threaded structure on the inside that fits the bottom of the anchor bolt 3 .

[0042] In the replaceable prestressed anchor bolt assembly described above, ...

Embodiment 3

[0044] Such as figure 1 , figure 2 and Figure 5 As shown, a device for replaceable anchor bolts, which includes an upper anchor plate 1, a lower anchor plate 2, an anchor bolt 3 connecting the upper anchor plate 1 and the lower anchor plate 2, between the upper anchor plate 1 and the lower anchor plate 2 The outer periphery of the anchor bolt 3 is covered with a plastic sleeve 7, and the upper and lower ends of the plastic sleeve 7 are shrunk and sealed by a heat shrinkable sleeve 8, and a non-metallic leveling nut 6 is installed on the heat shrinkable sleeve 8 at the upper end of the plastic sleeve 7. An upper nut 9 is installed on the top of the anchor bolt 3; the bottom of the anchor bolt 3 is fixed with the bottom sealing assembly 4.

[0045] The bottom sealing assembly 4 includes a nut box 4-1 and a hex nut 4-2 located in the nut box 4-1, the nut box 4-1 is welded on the lower anchor plate 2, and the hex nut 4-2 is connected to the bottom of the anchor bolt 3 Thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com