Mounting structure of disc hob

A disc-shaped hob and installation structure technology, applied in mining equipment, earth-moving drilling, tunnels, etc., can solve problems such as disadvantage, low installation efficiency, complicated loading and unloading process, etc., to improve the efficiency of replacement, simplify the installation method, install Convenient and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in combination with specific embodiments.

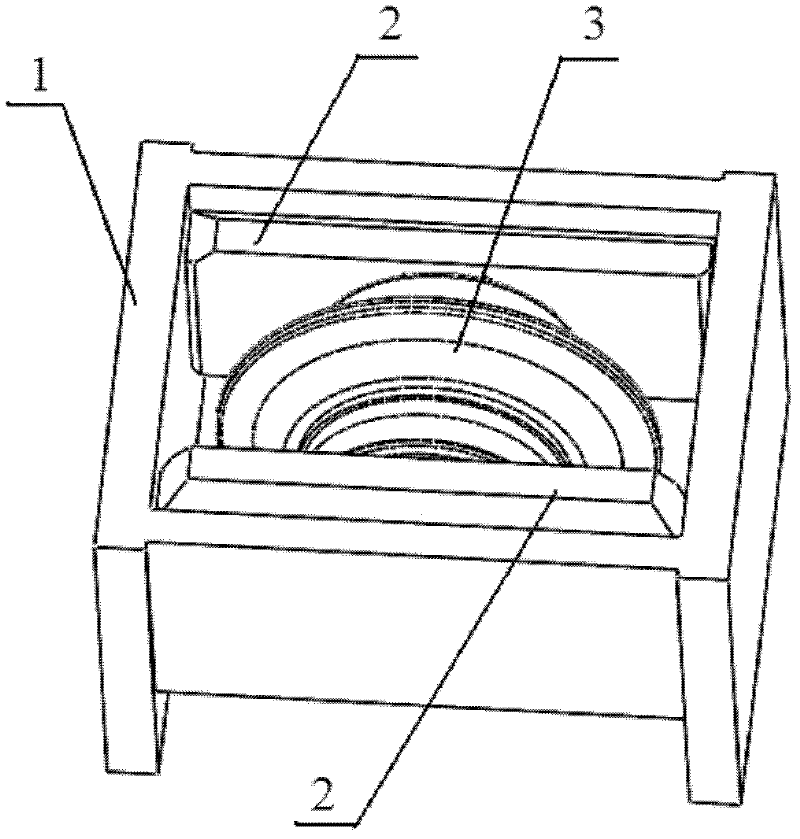

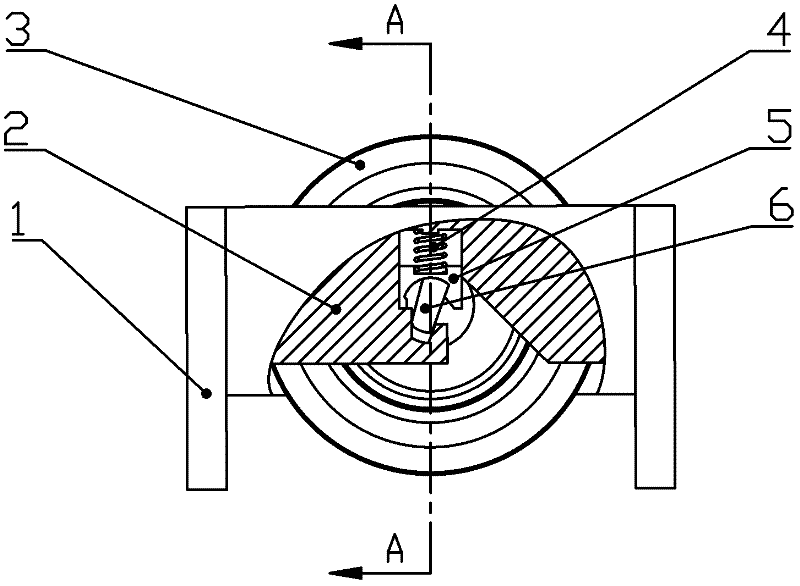

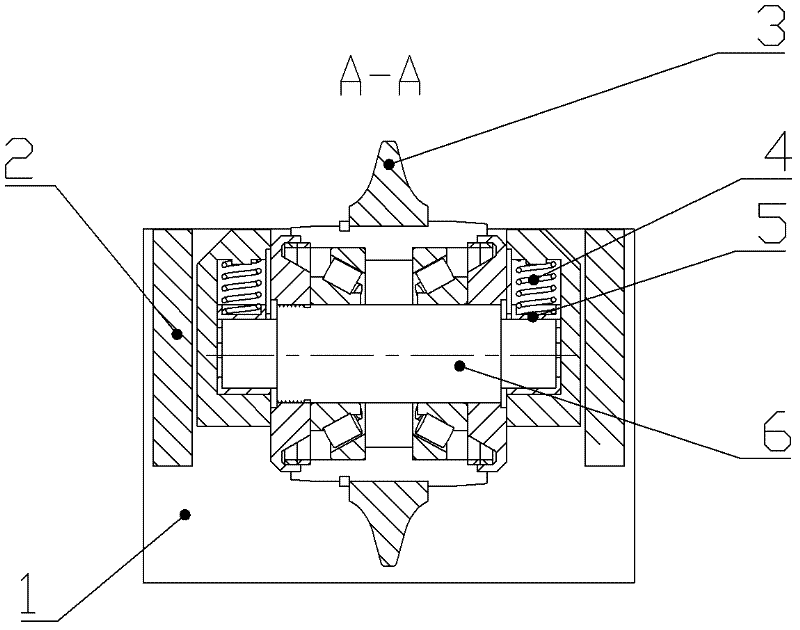

[0025] like figure 1 As shown, a disc-shaped hob installation structure of the present invention includes a hob shaft supporting frame 1 , a hob shaft seat 2 and a fixed cover plate 7 .

[0026] like Figure 8-1 and Figure 8-2 As shown, the two shaft ends of the hob central shaft 6 are milled and flattened to form a flat shaft head. There is an included angle of 3-20 degrees between the opposite sides of the cross section of each flat shaft head. Among the two relative arc surfaces, the radian of one arc surface is greater than that of the opposite arc surface; that is, the two shaft ends of the central axis 6 of the hob are cut into a flat shaft head shape with a bevel.

[0027] like Figure 4 As shown, the hob shaft support frame is a rectangular frame, and the inner sides of the two opposite side vertical plates of the hob shaft support frame 1 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com