Super-large diameter slurry balance shield tunneling machine

A mud-water balance, super-large diameter technology, applied in the field of shield machines, can solve the problems of low tool replacement efficiency, low tunneling efficiency, poor tool changing environment, etc., so as to improve the replacement efficiency and working environment, reduce construction costs, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

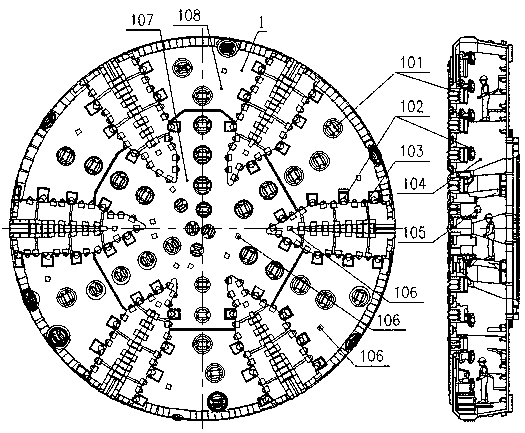

[0031]Embodiment 2, an ultra-large-diameter mud-water balance shield machine, the atmospheric cutterhead 1 is a box-beam cutterhead, which can also be replaced with an ordinary cutterhead, and the box-beam cutterhead includes a central block 107 and several peripheral Block 108, Perimeter Block 108 is uniformly arranged around the central block along the circumferential direction. The central block 107 and the peripheral block 108 are provided with several groups of normal pressure hob devices 101, normal pressure cutter devices 102 and scraper assemblies 103, and the normal pressure hob devices 101, normal pressure cutter devices 102 and scraper assemblies 103 The path is evenly set to cover the whole trajectory, and the normal pressure hob device 101 is equipped with a hob or a scraper under normal conditions. Both the central block and the peripheral block 108 are provided with a mud nozzle 106, which communicates with the mud circulation system 8, and the mud is sprayed on...

Embodiment 3

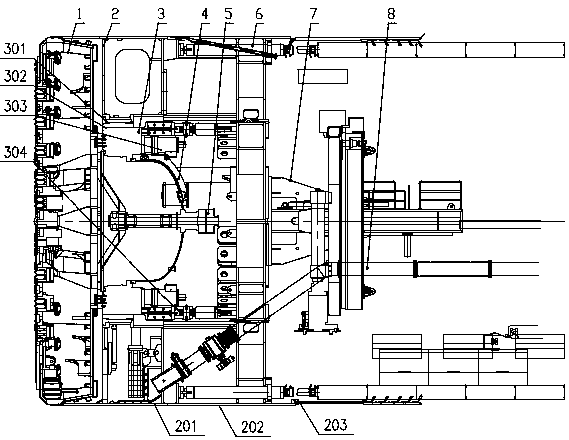

[0034] Embodiment 3, an ultra-large-diameter mud-water balance shield machine, the main drive system 3 includes a drive box assembly 302, the drive box assembly 302 is connected to the shield mechanism 2 through a swing ball structure 301, and the drive box assembly 302 There are several drive motors 303 and several telescopic oil cylinders 304 evenly arranged in the inside along the circumferential direction. One end of the oil cylinder 304 is connected with the drive box assembly 302, and the other end is connected with the shield mechanism 2, and the front and rear expansion and contraction of the normal pressure cutter head can be realized through the expansion and contraction of the expansion and contraction oil cylinder; The swinging of the normal pressure cutter head realizes the front and rear expansion and contraction of the normal pressure cutter head and the function of the cutter head swinging to over-excavate the soil body, which facilitates the replacement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com