Double-mode shield tunneling machine

A shield machine and dual-mode technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as failure to realize popularization and application, unreasonable overall design, and difficulty in shield machine excavation, so as to improve adaptability and shield Improve the construction efficiency of the structure, improve the integrated performance, and strengthen the effect of slag discharge and slurry discharge function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

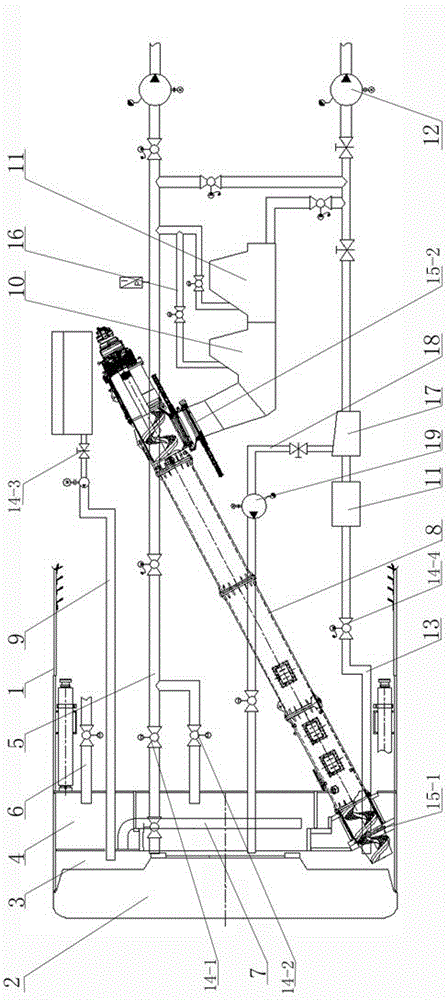

[0017] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] see figure 1 , a dual-mode shield machine, comprising a shield machine 1, a cutter head 2 is arranged at the front of the shield machine, an earth bin 3 is arranged behind the cutter head, and an air cushion bin is arranged behind the earth bin 3 4. There is a trailer behind the shield machine 1, the trailer is equipped with an earth pressure balance system and a mud-water balance system, the soil bin 3 and the air cushion bin 4 are connected with a slurry inlet pipe 5, and the air cushion bin The upper part of 4 is also connected with an air intake pipe 6, and a connecting pipe 7 is provided between the air cushion warehouse 4 and the soil warehouse 3; the earth pressure balance system includes a screw conveyor 8 extending into the soil warehouse 3, a The bentonite injection pipeline 9, the dilution box 10 at the rear o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com