Method for laying mine slurry pipeline in long and narrow section

A pipeline, narrow and long technology, which is applied in the field of laying slurry pipelines in narrow and long areas, can solve the problems of long construction period and achieve the effects of large laying distance, cost reduction and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described below.

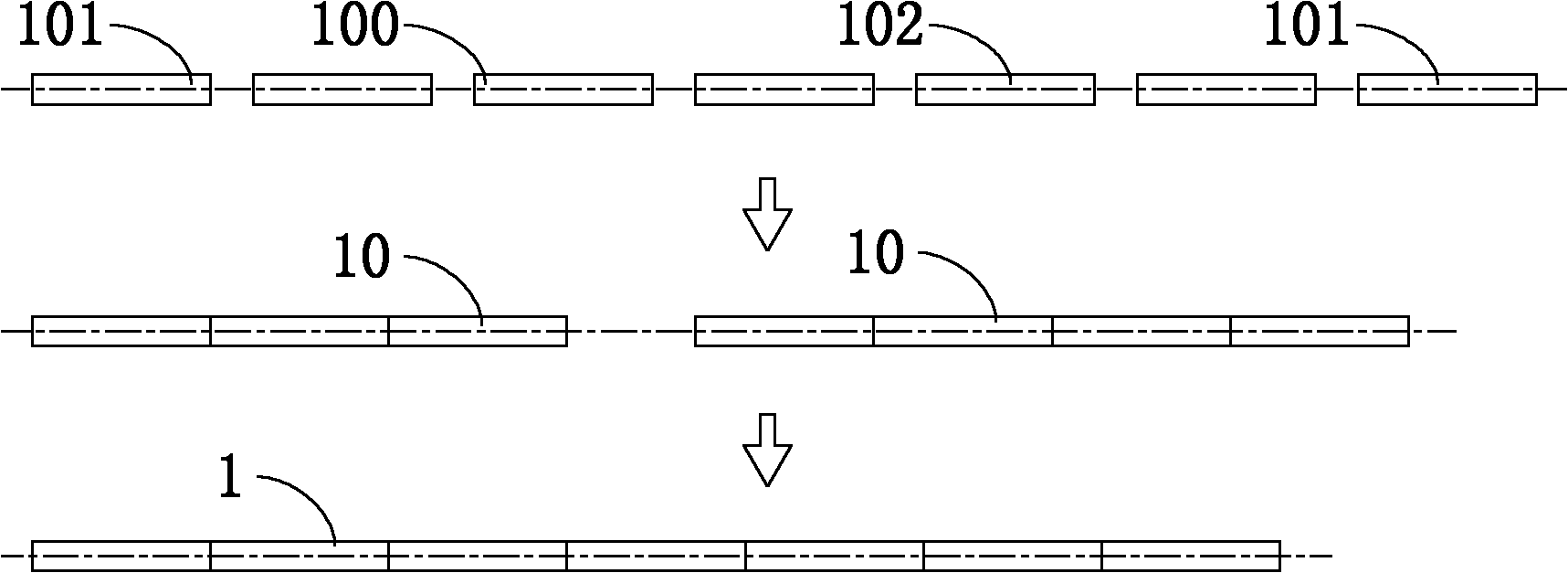

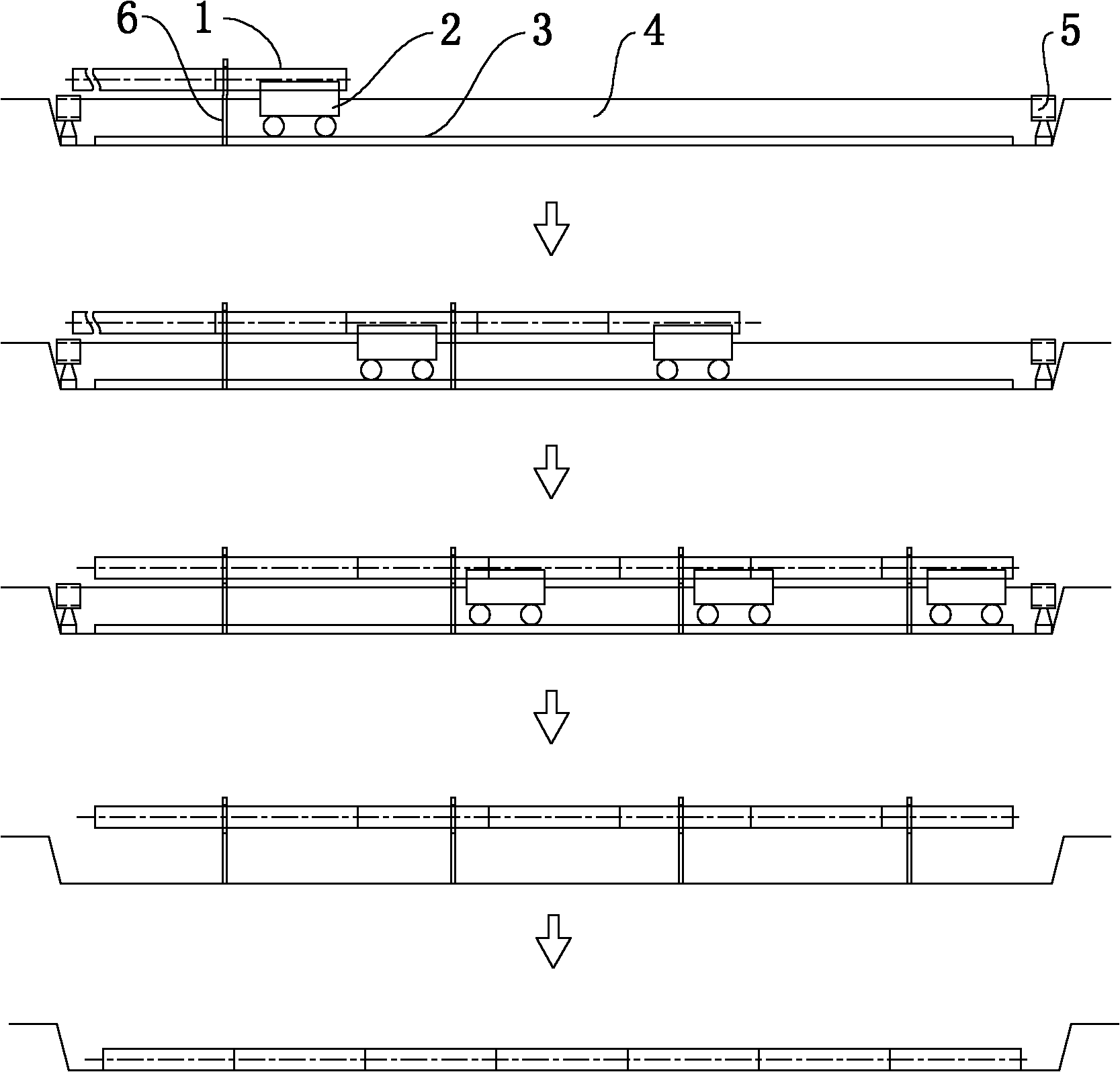

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the laying method of the slurry pipeline of the present invention in the narrow and long section is to use the junction of the straight pipe and the elbow as the dividing point to determine the length of the straight pipe section 1, and complete the laying between two adjacent elbows according to the following steps. The laying of the straight pipe section 1,

[0018] The first step, ditching and pipe welding: first complete the ditching operation of the straight pipe section 1, and then lay the track 3 in the pipe ditch 4, install the trolley 2 with the arc-shaped pipe seat 20 on the track 3, and the arc-shaped pipe The arc of the seat 20 matches the outer circle of the pipe, and the arc-shaped pipe seat 20 should be equipped with a cushion 21 to avoid hard contact, thereby preventing the coating layer on the pipe 100 from being damaged. Put a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com