Adjustable pneumatic pulp pipe sampler

An adjustable, sampler technology, used in pipeline systems, sampling devices, gas/liquid distribution and storage, etc., can solve the problems of low reliability, inconvenient use, and inability to adjust the size of the sampling volume, and achieves convenient use, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

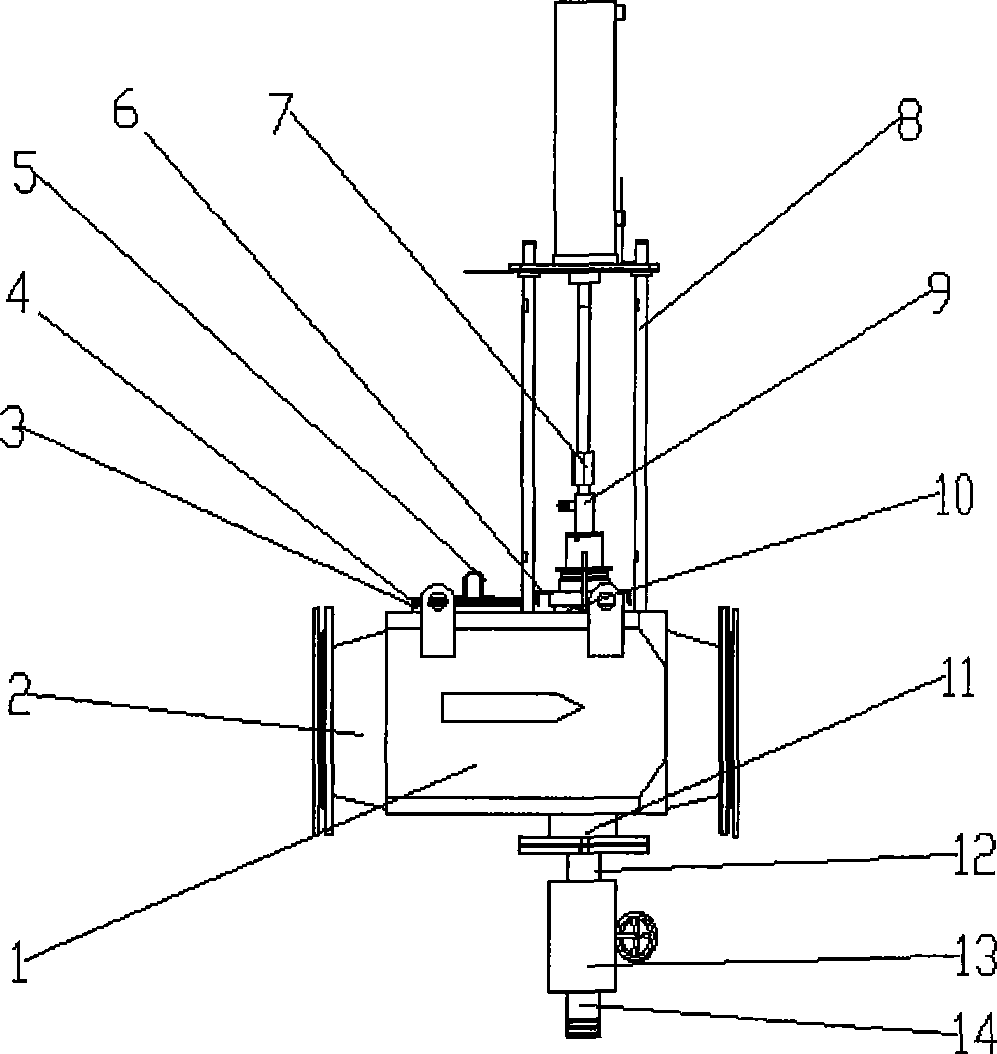

[0023] Connect the flange flowing into the slurry port of the box 1 to the slurry pipeline, the flange flowing into the slurry port and the box reducing flange 2 are connected by bolts, and the box reducing flange 2 and box 1 are welded, The other end of the box body 1 is also welded with a reducing flange 2 which is connected to the slurry pipeline through a flange that flows out of the slurry port. The box body 1 is square, the slurry pipeline is round, and the two different shape structures make the slurry self-stirring and mix evenly as much as possible.

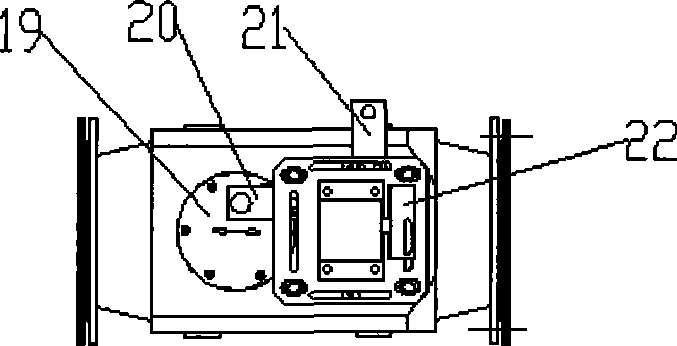

[0024] On the top surface of the box 1, relatively close to the mine inlet, weld an inspection flange 3, plug the flange hole with an inspection flange cover 19, and a repair flange sealing rubber gasket 4 for sealing in the middle. This structure is used for the overhaul and maintenance of the adjustable pneumatic slurry pipeline sampler. The maintenance personnel can open the maintenance flange to remove the debris adhered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com