Method for calibrating synchronous grouting quantity and grouting pressure of shield

A technology of synchronous grouting and grouting pressure, applied in the direction of measuring fluid pressure, volume measuring instrument/method, pressure difference measurement between multiple valves, etc., can solve the requirements that cannot fully meet the quality of formed segments and surface settlement And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

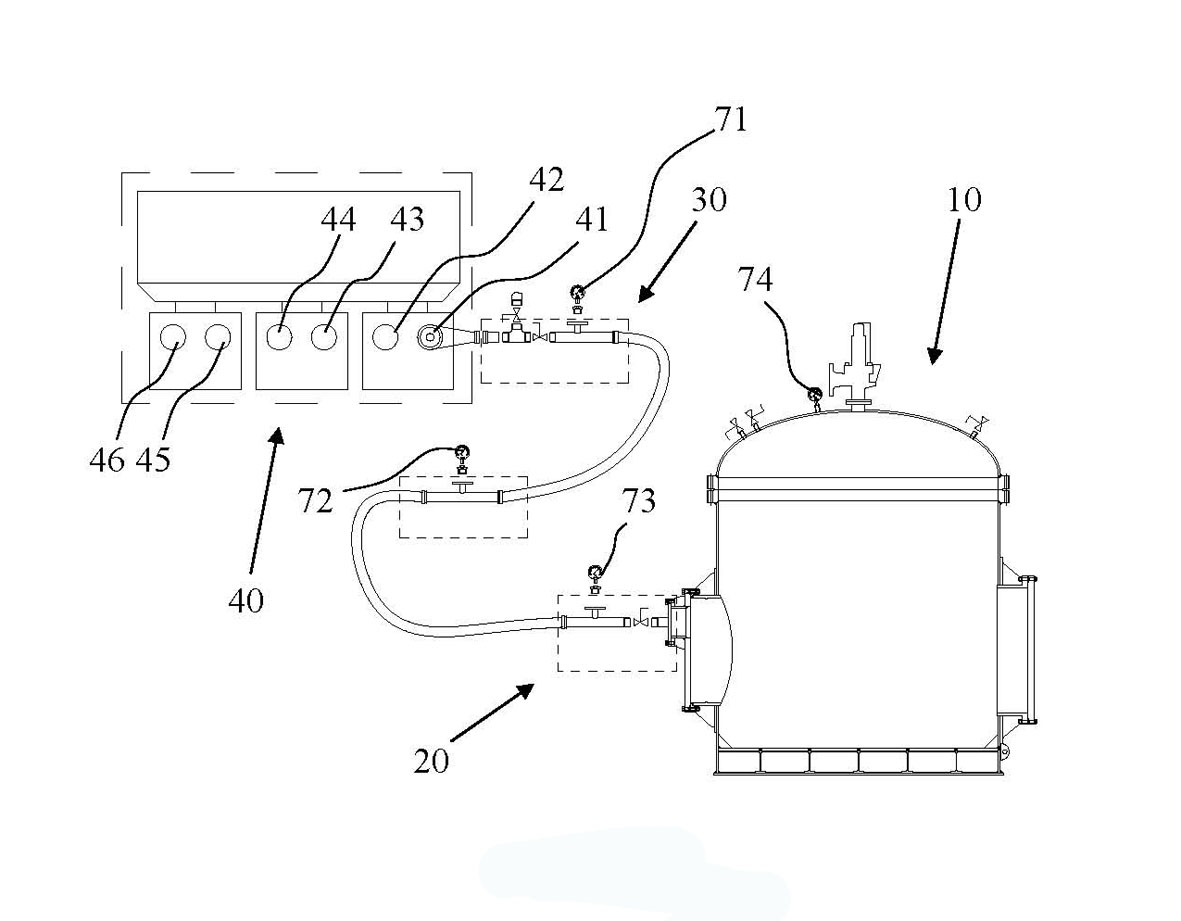

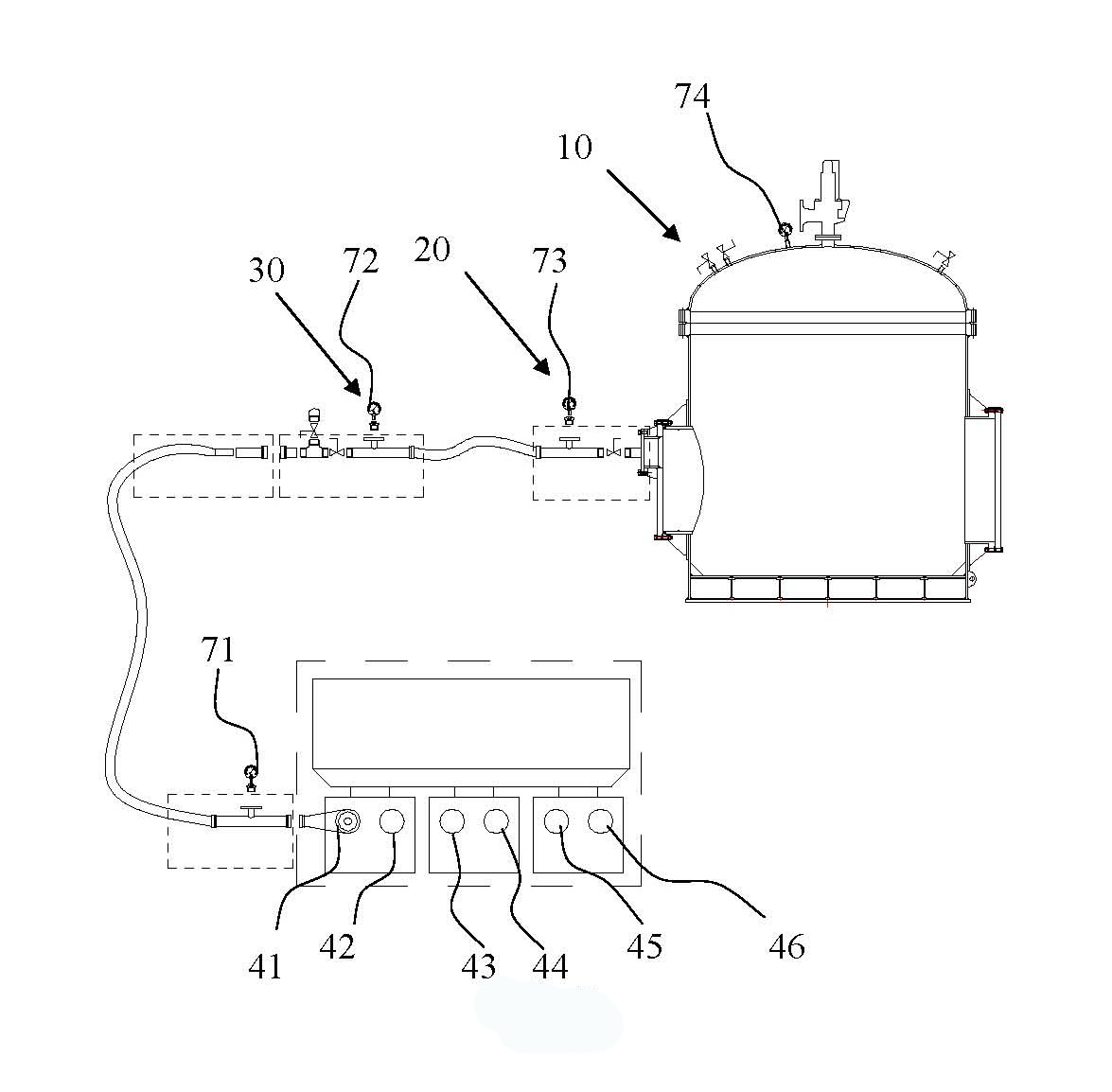

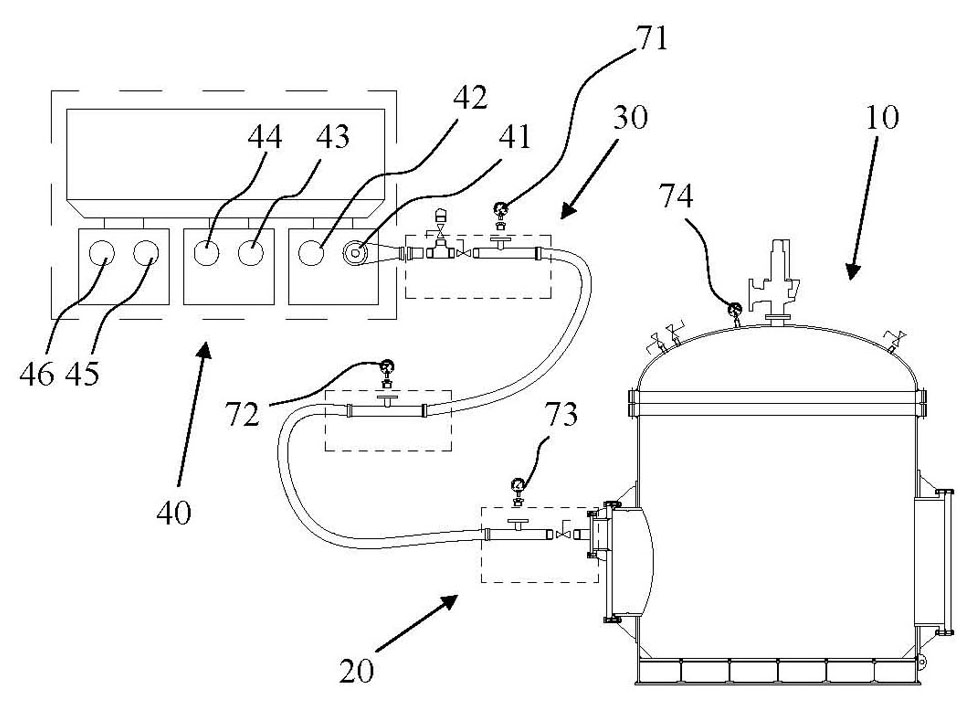

Image

Examples

Embodiment Construction

[0030] The present invention will be described below in conjunction with a specific embodiment.

[0031] The construction of a shield tunnel adopts the earth pressure balance shield of Ф14270mm. The outer diameter of the tunnel lining structure is 13950mm, the inner diameter is 12750mm, the thickness is 600mm, and the ring width is 2000mm: the maximum longitudinal slope of the main line of the shield tunnel is 5.5%, and the minimum flat curve radius is R700m. The total length is 1860m. The long-distance passage of the shield through the airport section and the short-distance passage of the airport oil pipeline have very high requirements for surface settlement. In view of the fact that the shield machine adopts the principle of "double control" to control the synchronous grouting, which can effectively reduce the rear deformation, the late settlement of the ground, and shorten the stabilization time of the late settlement, and the shield machine synchronous grouting pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com