Ore slurry pipeline transport device and anti-blocking control method thereof

A transportation device and pipeline technology, which is applied in the field of intelligent anti-blocking slurry pipeline transportation device and its anti-blocking control, can solve the problems of slurry transportation and other equipment impacts, and achieve the effect of improving transportation efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

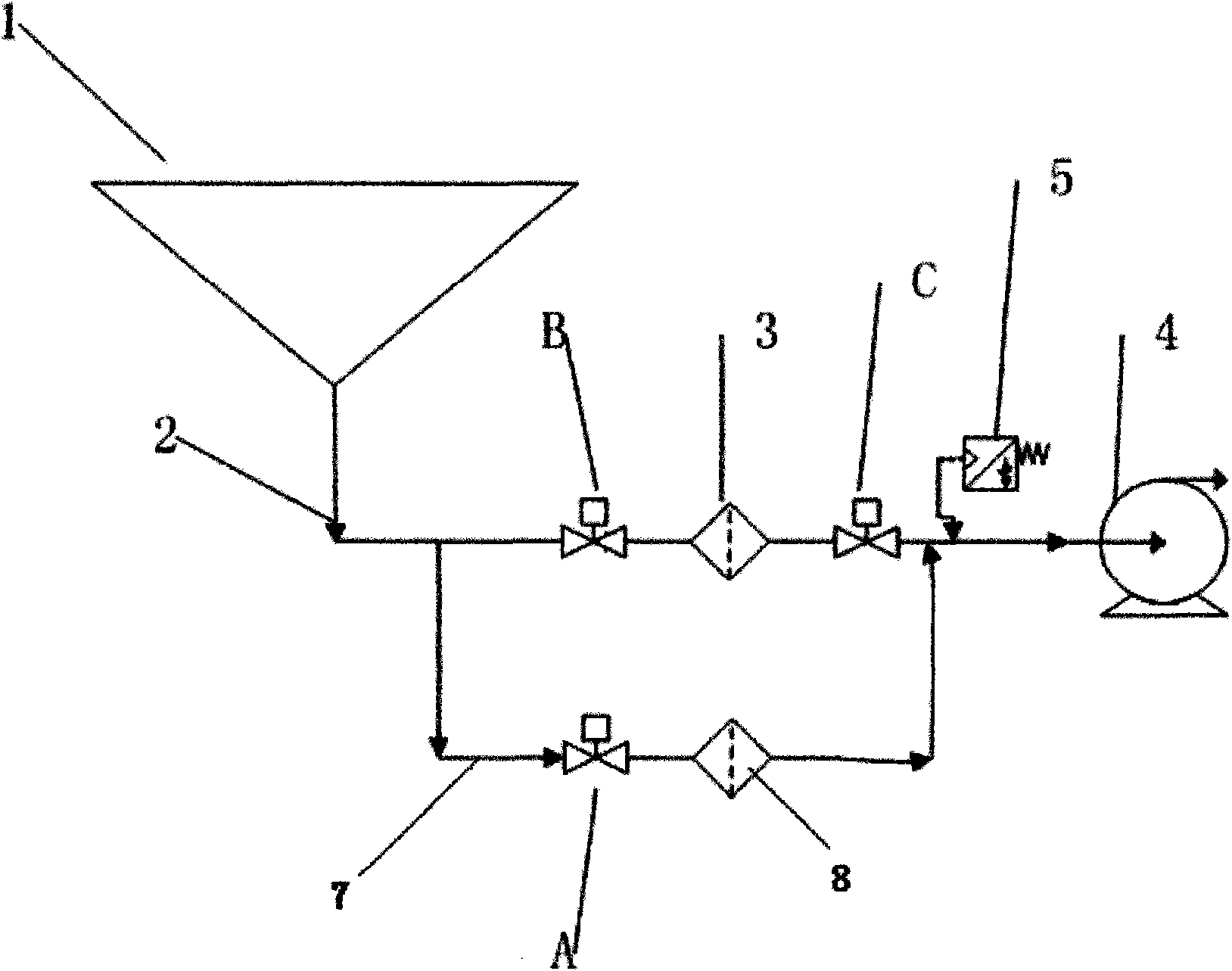

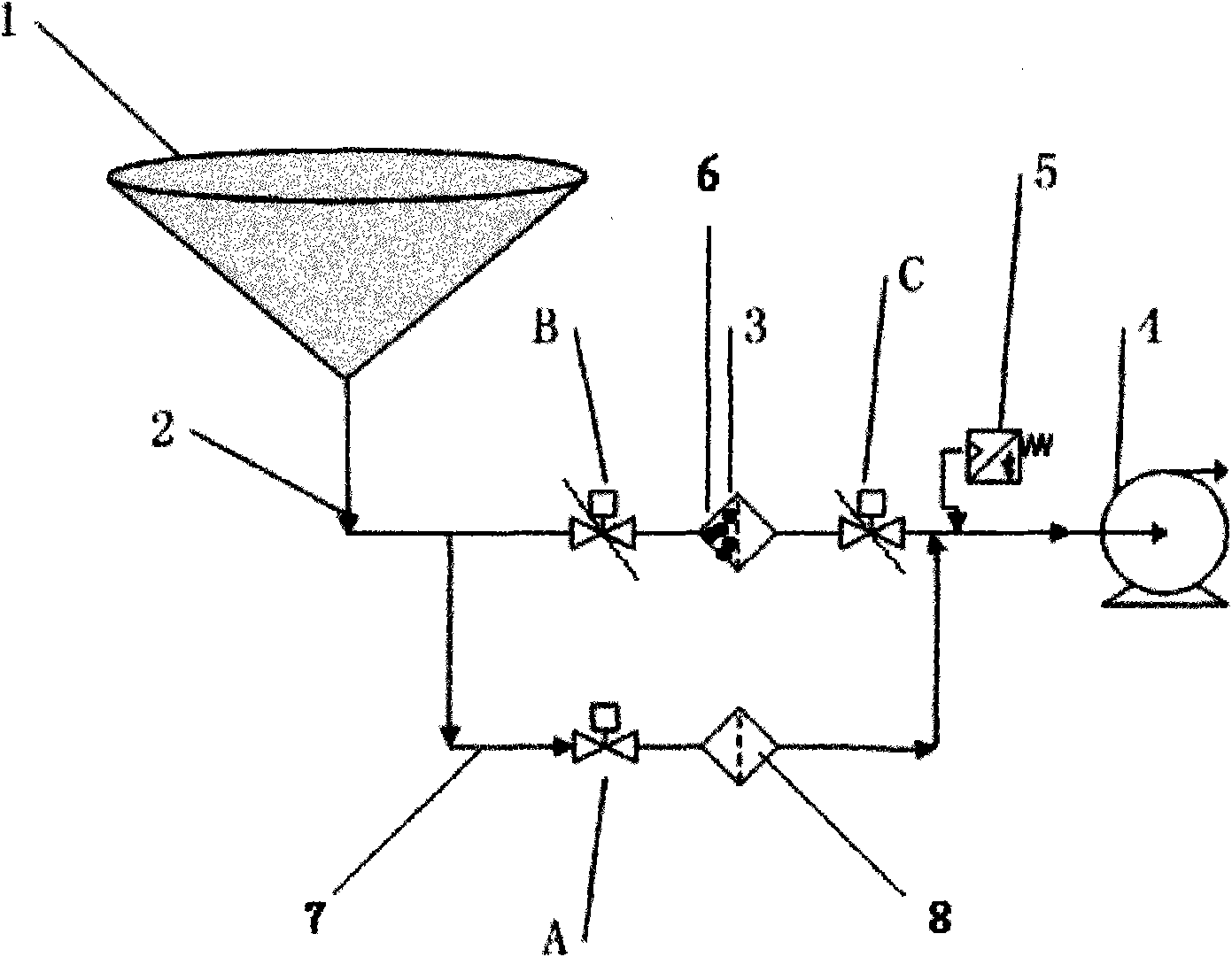

[0021] Such as figure 2 As shown, the slurry pipeline transportation device includes a thickening tank 1, an ore delivery pipeline 2, a filter screen 3, and an underflow pump 4. A valve B is set at the front end of the slurry pipeline segment blocked by debris, that is, the filter screen 3, and a valve C is set at the rear end. A negative pressure sensor 5 is arranged at an appropriate position at the rear end of the valve C. Set up a bypass pipeline to be connected in parallel with the slurry pipeline that will be blocked by sundries in this section. A bypass filter screen 8 is set in the coil pipeline, and the bypass pipeline is controlled by a bypass valve A. One end of the bypass pipe 7 communicates with the lower end of the concentration tank 1 , and the other end communicates with the underflow pump 4 .

[0022] When the ore pipeline is unblocked, the ore slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com