Positioning method for blocking position of ore slurry conveying pipeline

A technology for transportation pipelines and pipelines, which is applied in the field of transportation control, can solve problems such as high operating costs, scrapped pipelines, and economic losses of enterprises, and achieve the effects of reducing workload, low operating costs, and less hardware equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for locating the blockage position of the slurry transportation pipeline of the present invention includes the following steps:

[0030] The method for blocking the position of the slurry transportation pipeline of the present invention includes the following steps:

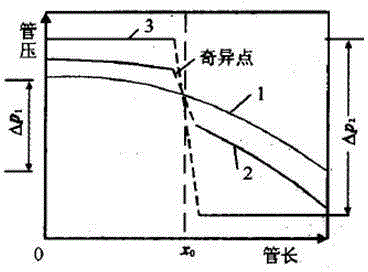

[0031] (1) When the slurry is transported normally, the hydraulic gradient curve of the entire pipeline is curve 1, and the pressure difference at both ends of the pipeline is △p 1 ;

[0032] (2) When the distance from the starting point of the pipeline χ 0 After a partial blockage occurs, the pipeline before the blockage point is under pressure, and the pipe section after the blockage point loses part of its energy supply, and its hydraulic slope curve is curve 2;

[0033] (3) When the distance from the starting point of the pipeline χ 0 After a complete blockage occurs, the pipeline is holding back pressure before the blockage point, and the slurry in the pipeline basically stops flowing, and the pipe ...

Embodiment 2

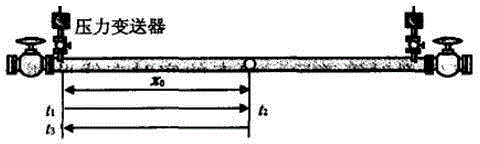

[0050] A domestic slurry pipeline was demagnetized in 2014 because the slurry was not demagnetized by a demagnetizer. At that time, the pumping station of the slurry pipeline was shut down due to thunderstorms. When the slurry was shut down and restarted, the outlet pressure was found to rise sharply. Personnel experience judges that the pipeline is blocked. The inner diameter D of the slurry pipeline is 253mm, and the slurry density ρ is 2073kg / m 3, The elastic modulus E of the pipeline material is 2.07*10^11pa, the wall thickness e of the pipeline is 10mm, the distance L between the No. 1 pumping station and the downstream pumping station is 12.5 kilometers, and the bulk elastic modulus of the conveying slurry measured by experiments is 27*10^ 7pa, the negative pressure wave velocity measured by theoretical calculation is about 989m / s, and then through the SCADA computer program, the time difference Δt between the two transmissions of the positive pressure wave to the upstream ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com