Biogas slurry pipeline fertilizing device

A fertilization device and pipeline technology, which is applied in the field of biogas slurry pipeline fertilization equipment, can solve the problems of pipe burst, common water pumps are easy to block, corrode, etc., and achieve the effects of reducing production management costs, facilitating control of biogas slurry concentration, and low pipeline construction and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

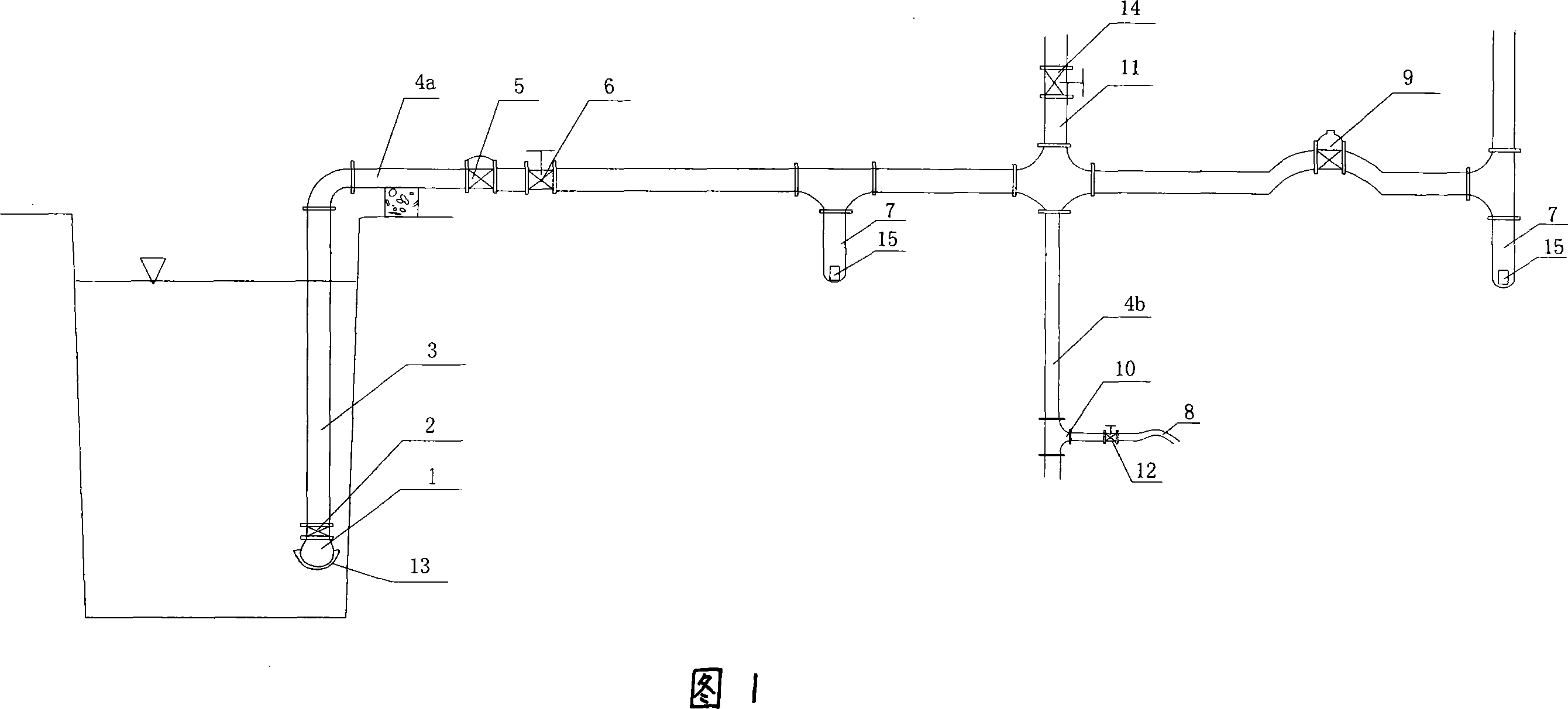

[0015] Embodiment: As shown in Fig. 1, a kind of biogas slurry pipeline fertilization device suitable for farming manure returning to the field includes a submersible sewage pump 1 placed in the lower part of the liquid storage tank, and the suction port of the sewage pump is 10 meters away from the bottom of the liquid storage tank. The distance is 500-800mm; the filter screen 13 coated on the sewage pump 1; the check valve 2 arranged above the submersible sewage pump; the liquid inlet pipe 3 connected with the check valve 2; The main pipeline 4a that the liquid inlet pipe 3 communicates; the quick release valve 5 and the gate valve 6 installed on the main pipeline 4a; the branch pipeline 4b that communicates with the main pipeline 4a; the main pipeline 4a and the branch pipeline 4b The diameter is not less than 50mm; the water outlet pile 10 connected with the branch pipe 4b, the diameter of the water outlet pile 10 is between 25-50mm, and the length is 200-300mm; the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com