Patents

Literature

64results about How to "Normal pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

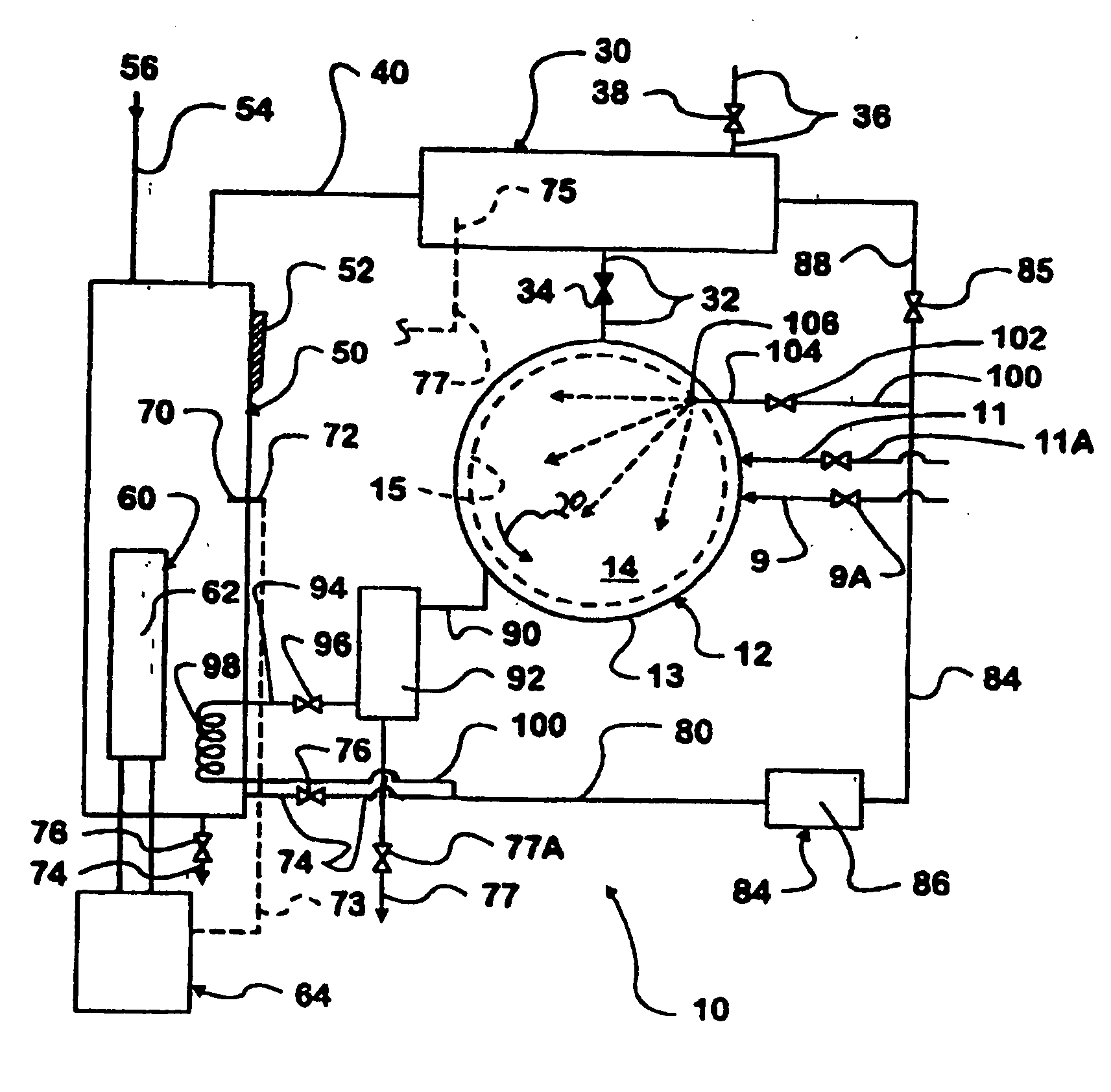

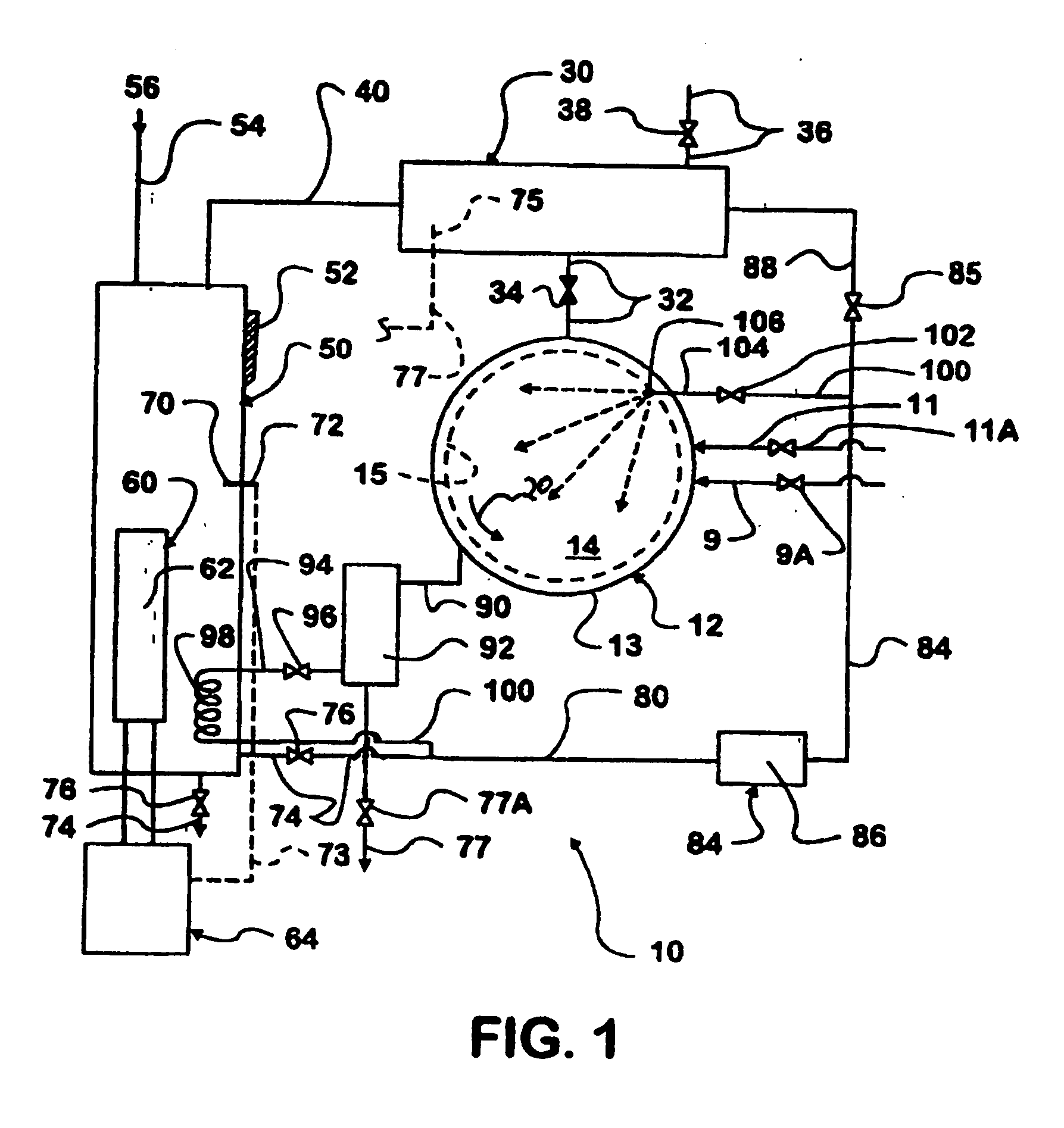

Washer method and apparatus

InactiveUS20070130698A1Improve washing effectIncrease water flow areaOther washing machinesTextiles and paperEngineeringRefrigeration

An improved washer (10, 210, 710) having a quick fill (32, 34) and a quick drain (36, 38) with reduced overall wash time is provided. Means are provided for doing a very cold wash to permit machine washing of fine clothing that heretofore was hand washed or dry cleaned. The washer (10, 210, 710) can be provided with one (30), two (224, 230) or three tanks (750A, B & C, 950A, B & C) for water at three temperatures, very cold (refrigerated), tap or city water supply temperature, or hot water. The very cold can be made by a refrigeration or chilling means (62, 64, 98), located in or adjacent the very cold water tank. The hot water can be provided from or have a heater (230, 320, 750C, 950C) therein one of the tanks. The washer also includes an improved embossed basket (600) with increased surface area. The features can be built into a new washer or retrofitted into an existing washer. Very cold water wash and rinse can be provided so that cloths, and particularly clothes such as made of wool, rayon, acetate or other clothes, such as leathers or furs, usually dry cleaned or hand washed, can be machine washed with the present invention without use of hazardous chemicals or shrinkage.

Owner:KIM SU HEON

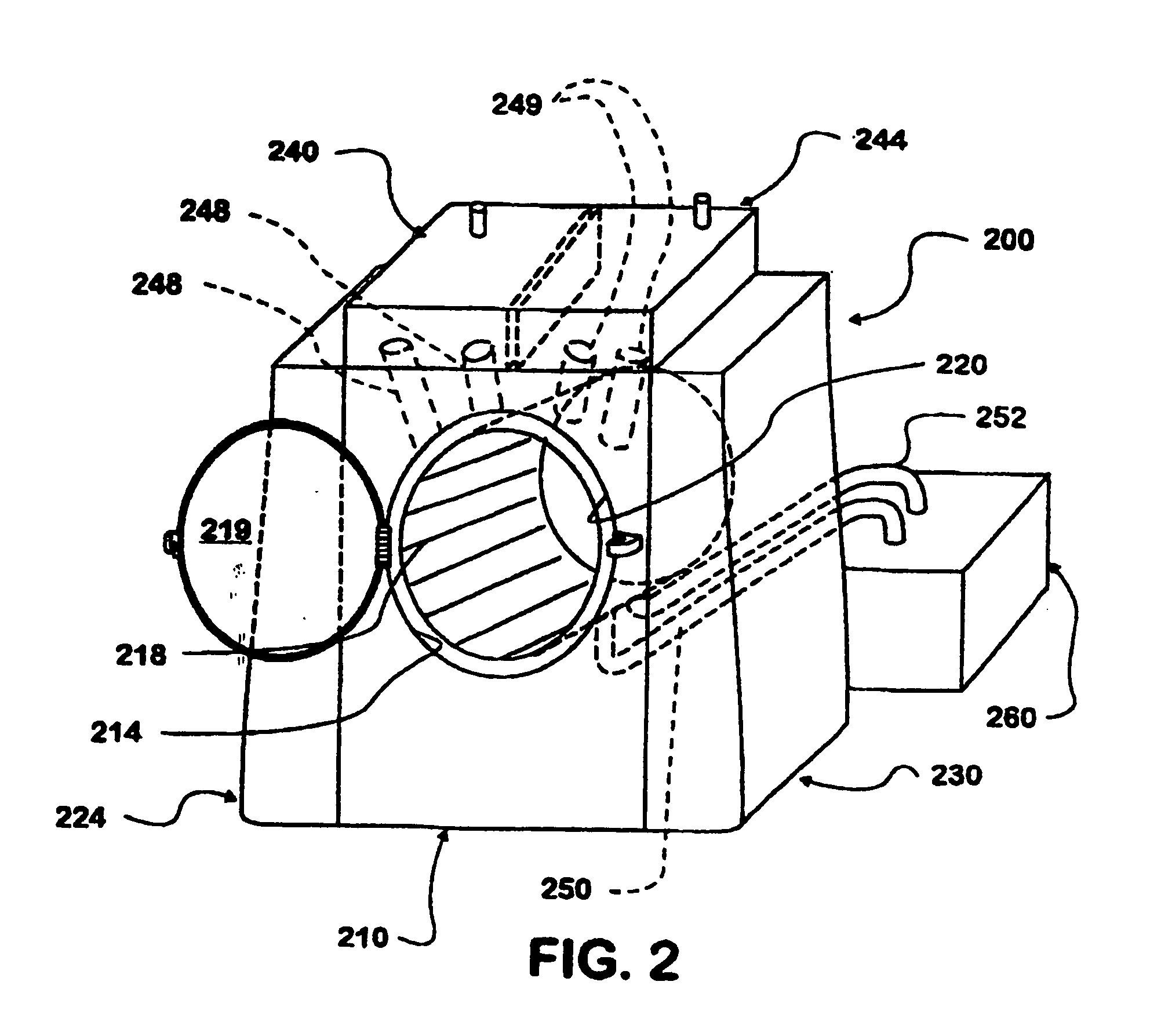

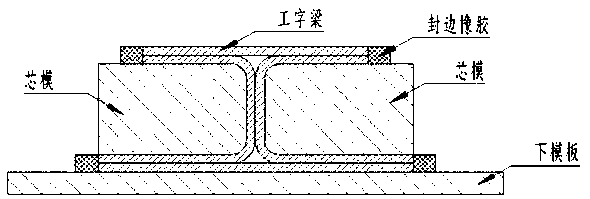

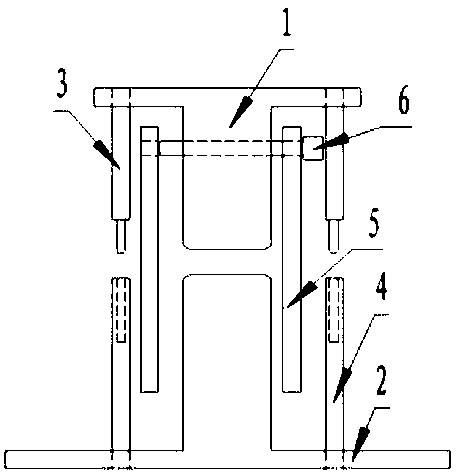

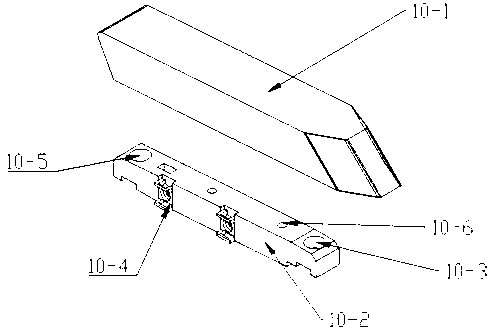

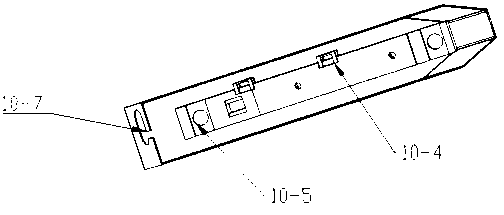

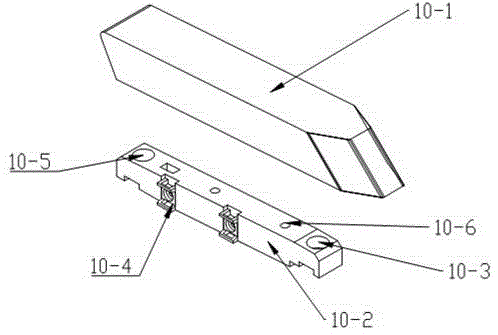

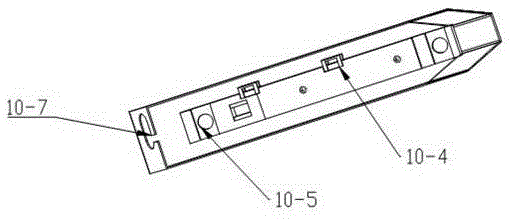

Die and method for forming composite material I-shaped beam

ActiveCN110385861AAvoids problems with loss of bottom layer supportGood molding and curing effectDomestic articlesShaped beamMechanical engineering

The invention relates to a method for forming a composite material I-shaped beam. The method is characterized by comprising the following steps: step one, first separately laying and compacting a leftC-shaped member, a right C-shaped member, and upper and lower cover plates of an I-shaped beam on an upper die body of a forming die, a lower die body of the forming die and a pressing plate; step two, after the laying and compacting work of all prepreg blanks of the I-shaped beam is finished, taking down the blanks from the die bodies, and directly assembling the upper die body of the forming die, the lower die body of the forming die and the pressing plate by a positioning and supporting structure and moving pins; step three, finishing package of an assembly obtained in the second step by using a vacuum bag in a tooling vacuum bag packaging area; and step four, transferring a packaged system in an autoclave for curing. The die for forming the composite material I-shaped beam comprises the upper die body of the forming die and the lower die body of the forming die; the upper die body of the forming die and the lower die body of the forming die are in H-shaped vertical involution; andthe positioning and supporting structure is arranged between the upper die body of the forming die and the lower die body of the forming die.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

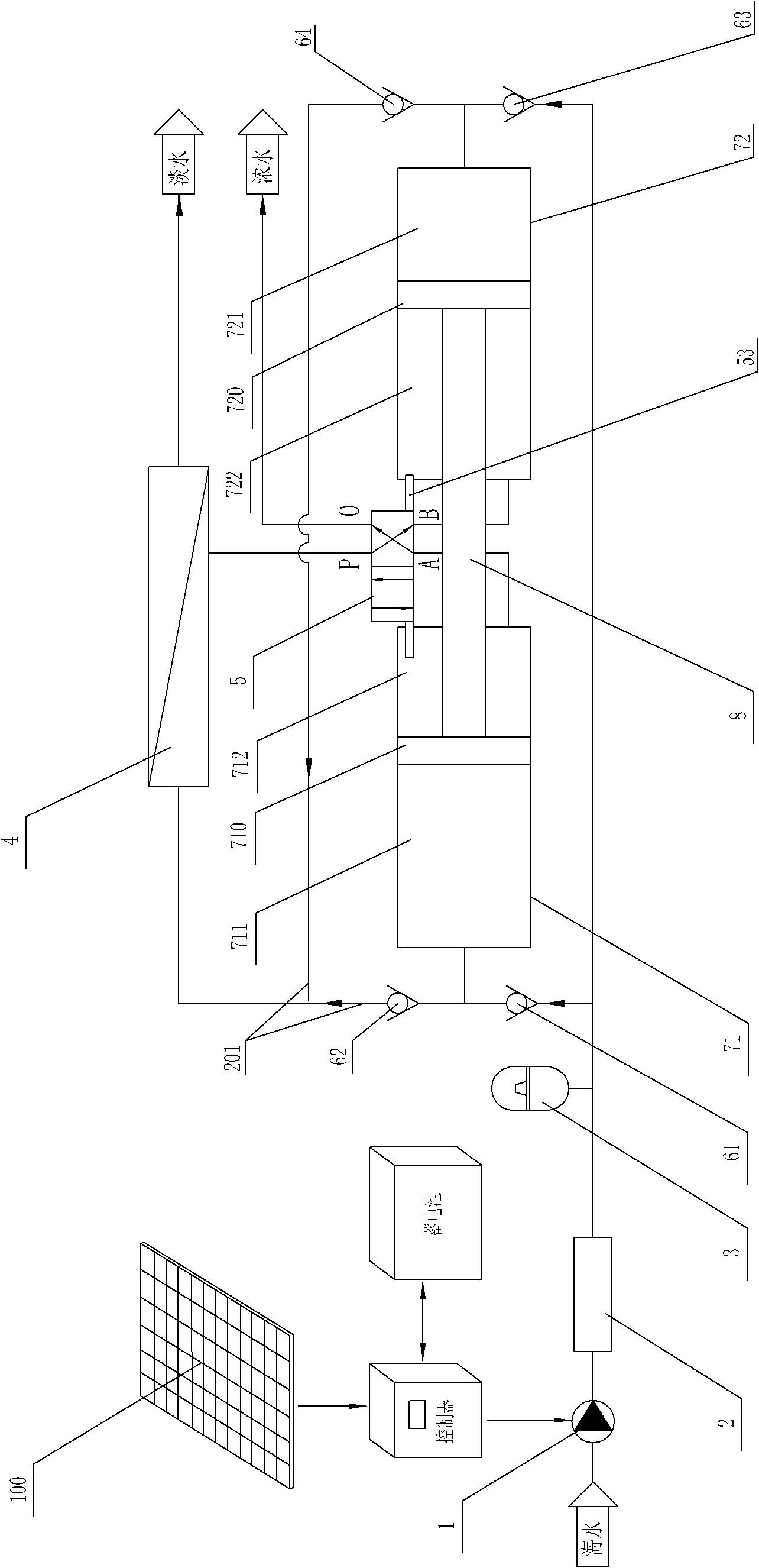

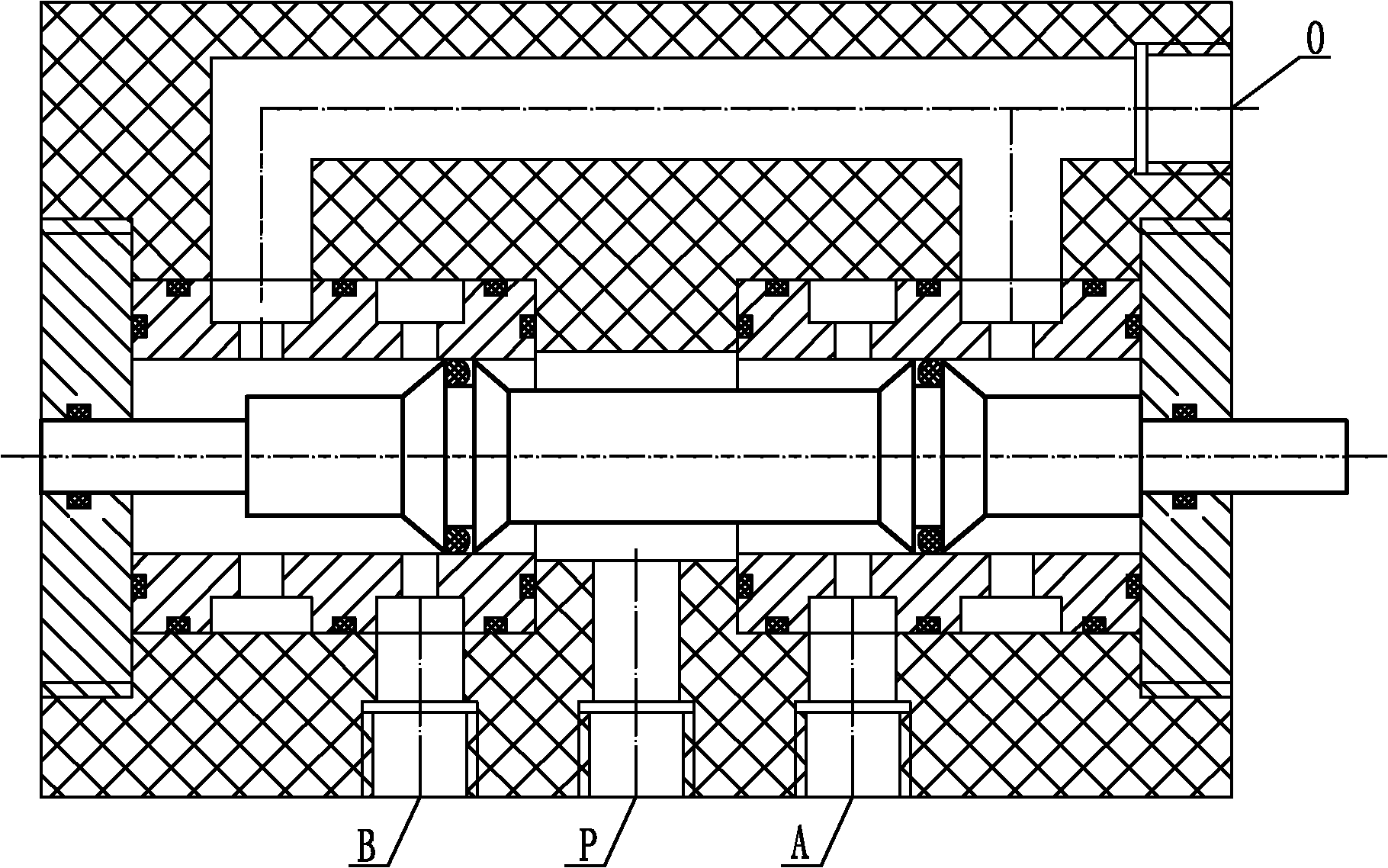

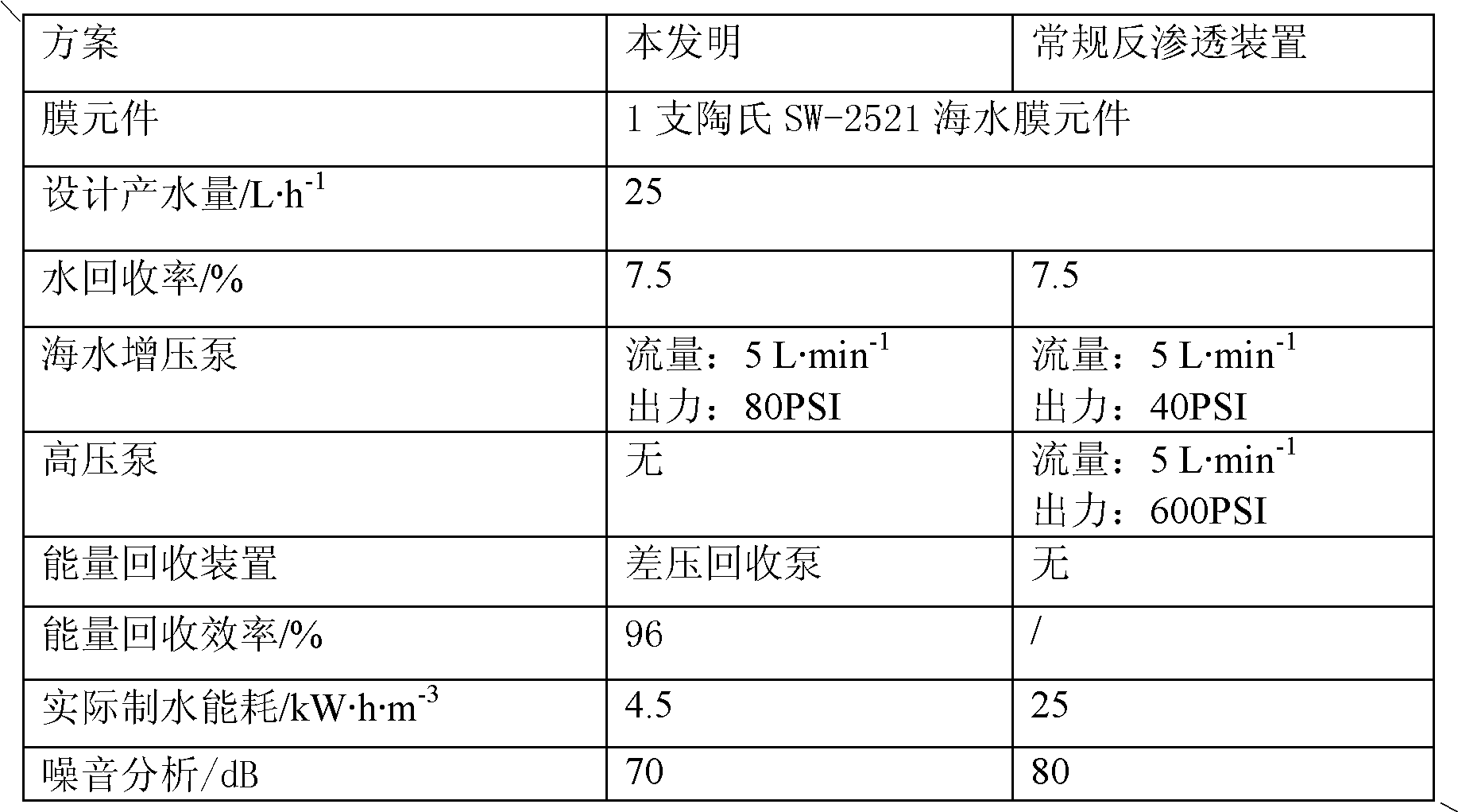

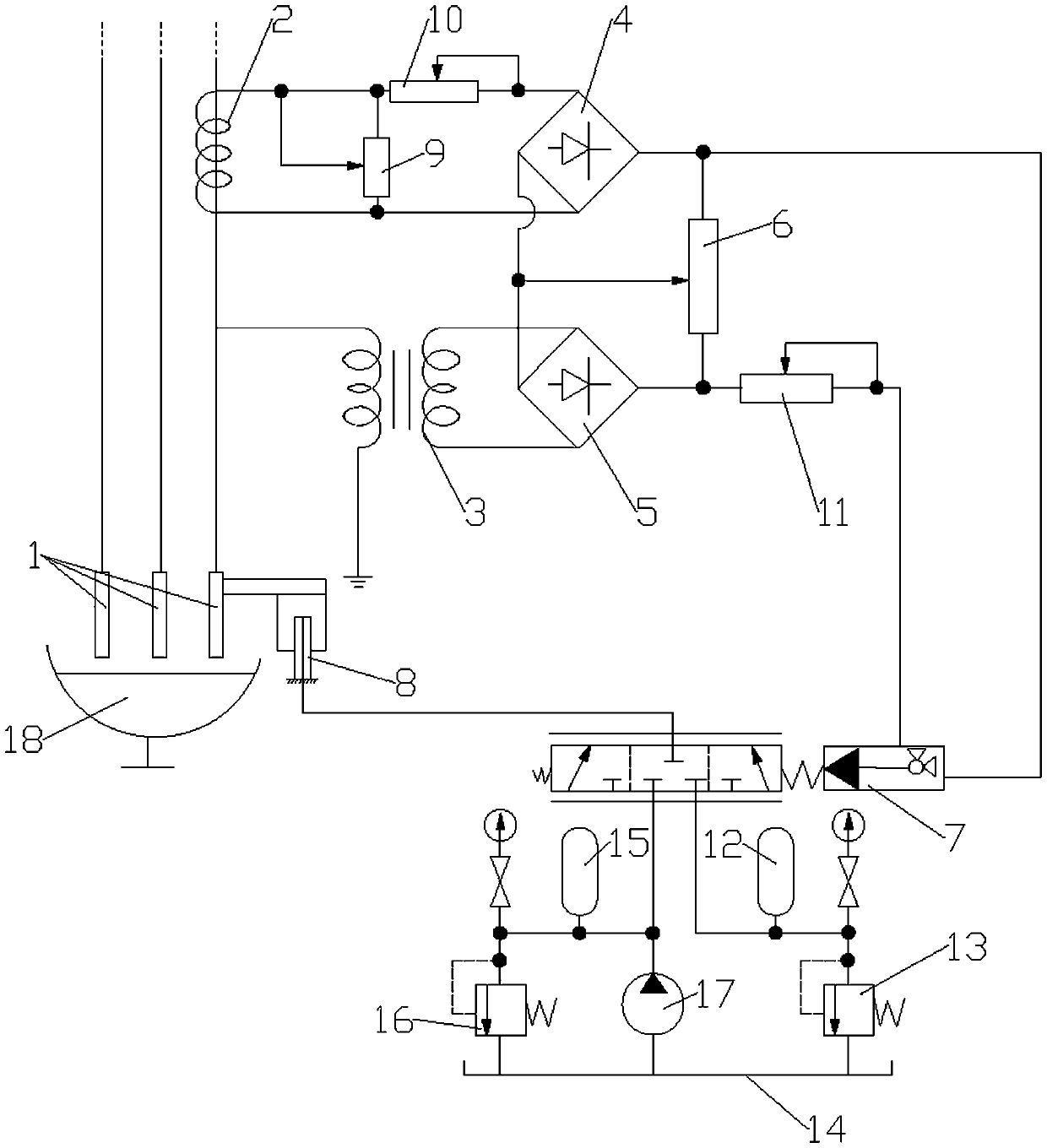

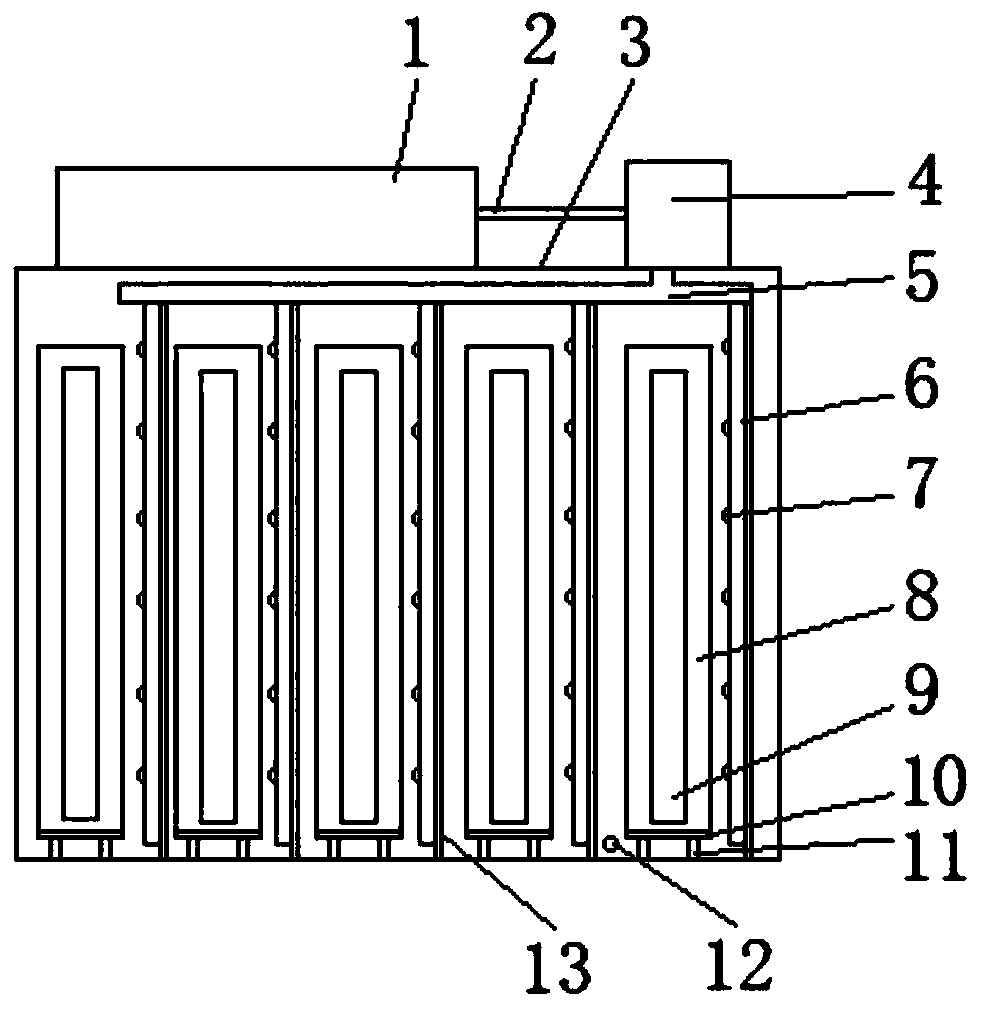

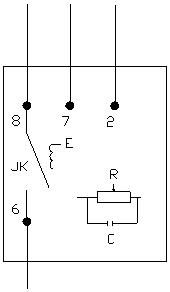

Photovoltaic solar reverse osmosis desalination device

ActiveCN102060354AImprove power generation efficiencyLess investmentBatteries circuit arrangementsGeneral water supply conservationPhotovoltaic solar energyDifferential pressure

The invention provides a photovoltaic solar reverse osmosis desalination device. The device consists of a photovoltaic solar direct current power supply system and a reverse osmosis desalination system, wherein the photovoltaic solar direct current power supply system comprises a solar photovoltaic battery plate, storage batteries and a controller, wherein the output end of the solar photovoltaic battery plate is connected with the controller; and the storage battery set is connected with the controller bi-directionally. As the photovoltaic solar direct current power supply system is adopted to the device provided by the invention, a direct current drive is adopted to reduce the power loss caused by the inversion process and increase the generating efficiency of the photovoltaic solar power supply system and the investments of the photovoltaic solar power generating system and the inverter can be relatively reduced. The four-way reversing valve provided by the invention is characterized by comprising a motion valve; when the piston moves to a limiting position, the valve rod is pushed for conversion, thus the differential pressure recovery pump can switch to a working state automatically; and the adaptabilities of the flow and pressure of the system are good.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

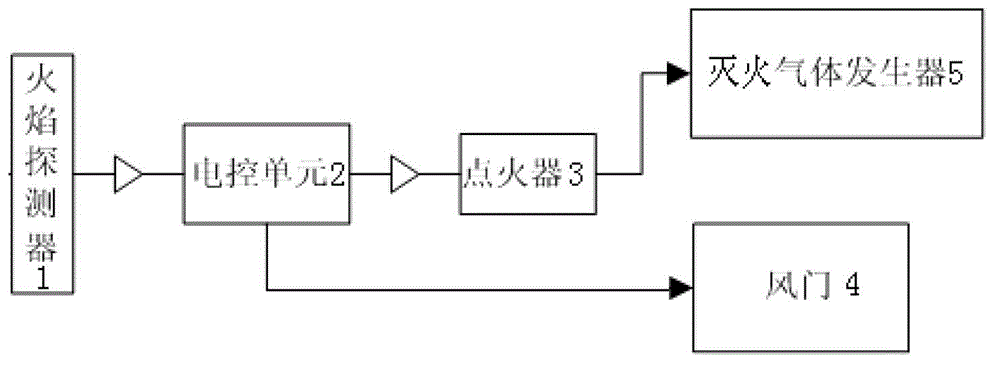

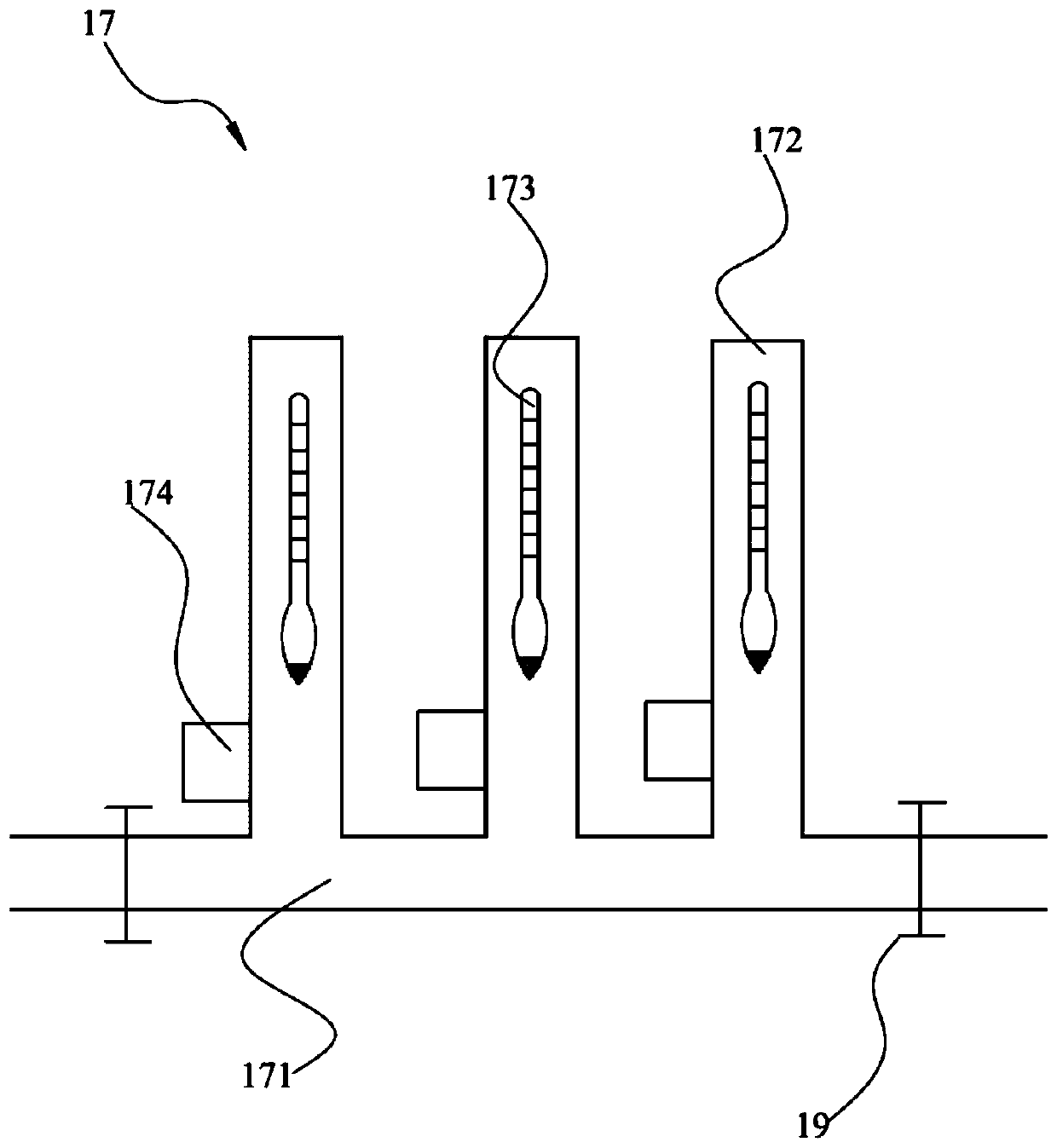

Automatic fire extinguishing system and automatic fire extinguishing method for electric automobile

The invention provides an automatic fire extinguishing system of an electric automobile. The automatic fire extinguishing system comprises a plurality of flame detectors, a ventilation door, an electrical control unit, a fire-extinguishing gas generator and an igniter, wherein the flame detectors are arranged in the power battery accommodating position of the electric automobile, the ventilation door is arranged in the power battery accommodating position, and the igniter is used for igniting fire-extinguishing gas generator; an outlet of the fire-extinguishing gas generator is connected with confined space; the flame detectors transmit detection signals to the electrical control unit; and the electrical control unit controls the igniter and the ventilation door. The fire extinguishing system is safe and reasonable in arrangement.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

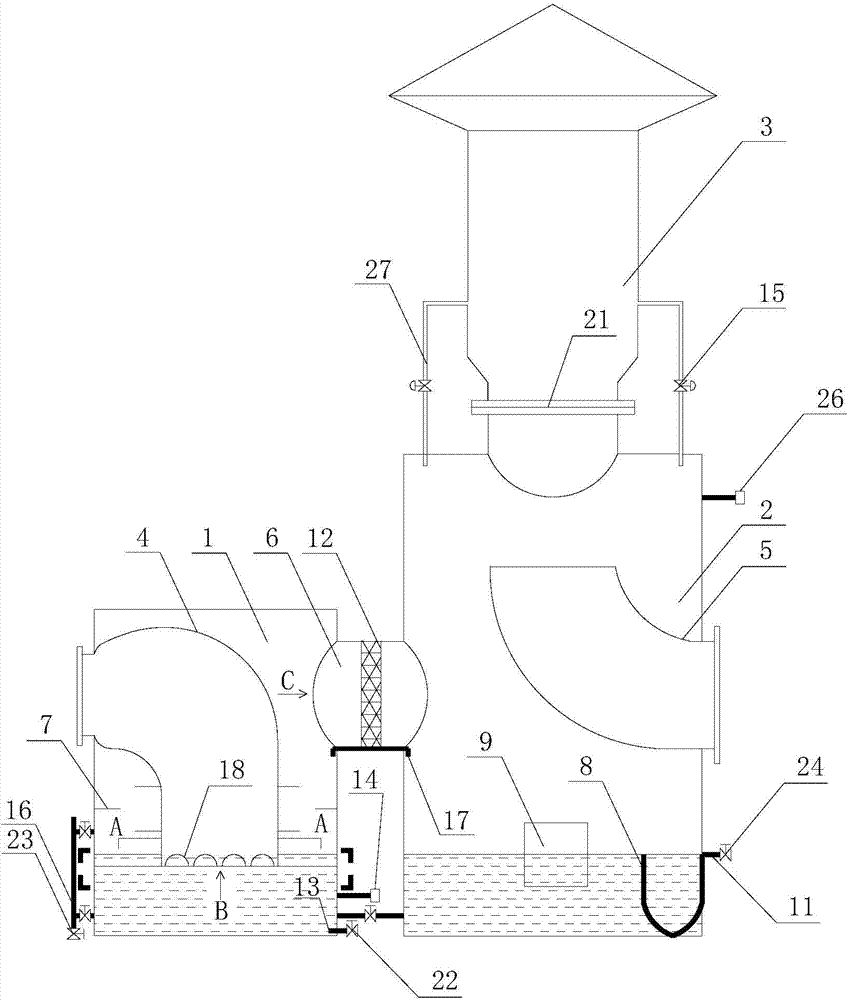

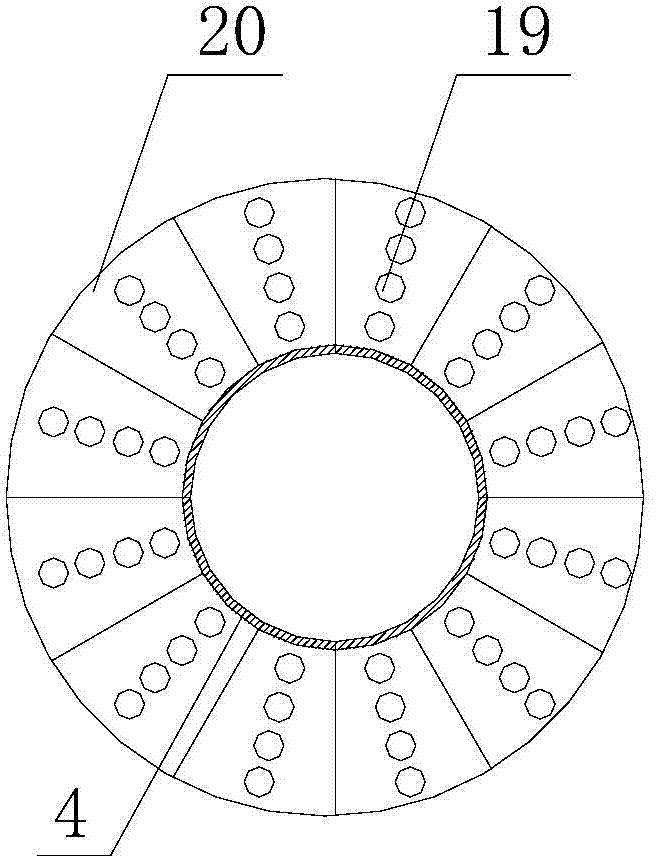

Water sealing fire retardance explosion venting device

The invention discloses a water sealing fire retardance explosion venting device which comprises a fire retardance device and an explosion venting machine. The fire retardance device comprises a fire retardance barrel body, an air inlet pipe, an air outlet pipe and a water filtering metal ring net. One end of the air inlet pipe is placed out of the fire retardance barrel body, the other end of the air inlet pipe extends into the fire retardance barrel body and is inserted to the position below a sealing water liquid level, and the water filtering metal ring net is arranged above the sealing water liquid level and is arranged outside the air inlet pipe in a sleeving mode. The explosion venting machine comprises an explosion venting barrel body, an exhaust pipe and an explosion venting pipe. The exhaust pipe and the explosion venting pipe are communicated with the explosion venting barrel body. The fire retardance barrel body is communicated with the explosion venting barrel body through the air outlet pipe and a communication pipe arranged at the bottom. An explosion piece is arranged in the explosion venting pipe. An air outlet end pipe opening of the air inlet pipe is sealed. An exhaust hole is formed in the side wall, placed below the sealing water liquid level, of the air inlet pipe. The exhaust hole is connected with an air guiding pipe. Air guiding holes for air discharging are distributed in the air guiding pipe. The instability and the acute fluctuation of the liquid level caused when air is discharged from the device exhaust pipe can be avoided, water level control is convenient, and the safety and the reliability of the device are improved.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

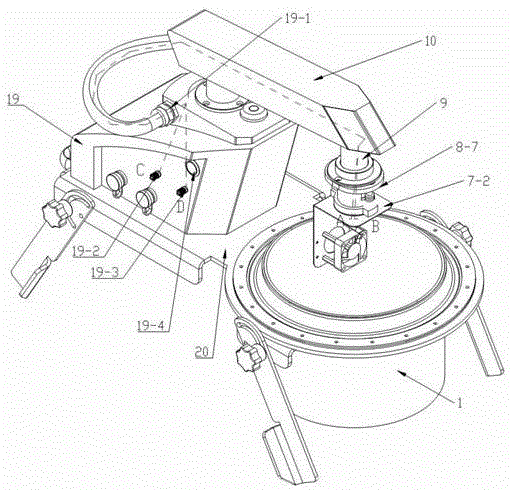

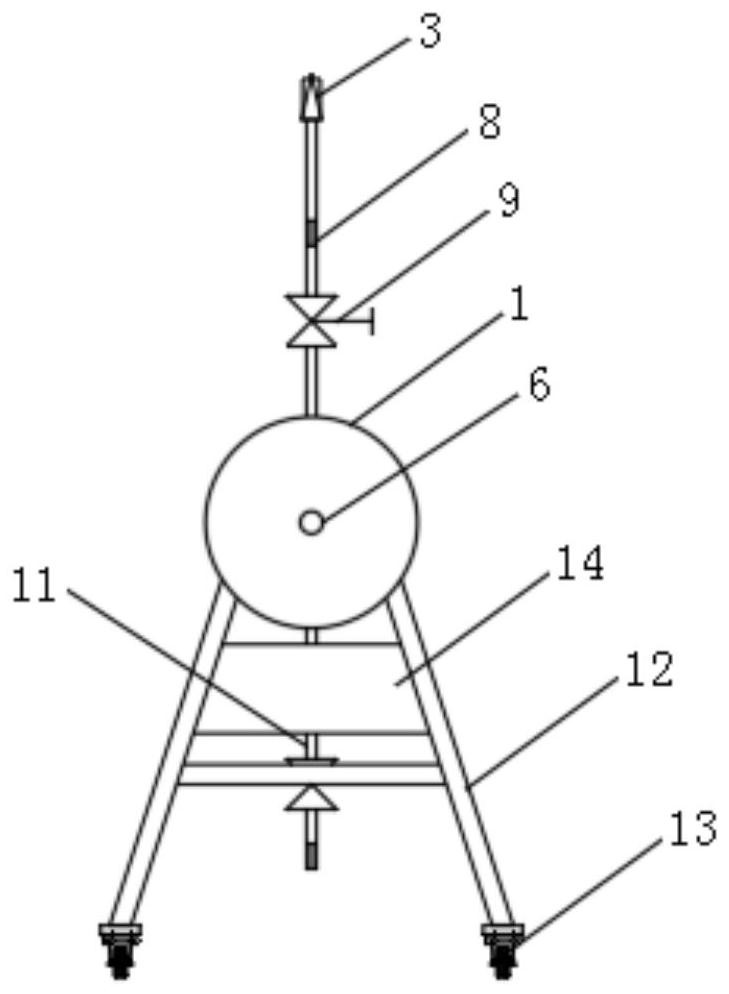

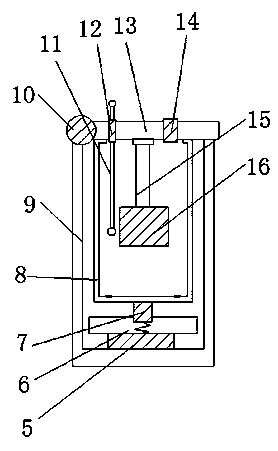

Soil gas flux detector and determination method

The invention relates to a soil gas flux detector comprising a soil ring (1), supporting legs (2), a pedestal (20), a gas chamber (7), a protective cover (8), a line passing shaft (9), and a control box (19). The flux detector is characterized in that a sealing ring (5) and a pressing ring (3) are arranged above the pedestal (20); the supporting legs (2) are arranged below the pedestal (20); supporting led slide grooves (16) and supporting leg rotation shafts (14) are arranged on the supporting legs (2); a buffering device (8-7) is arranged in the gas chamber (7), the protective cover (8), and the line passing shaft (9); and a return button (19-4) is arranged on the control box (19). With the device provided by the invention, problems such as exposed gas pipe and line, gas chamber offset, and large measuring error of soil gas flux detector can be solved.

Owner:北京萨维福特科技有限公司

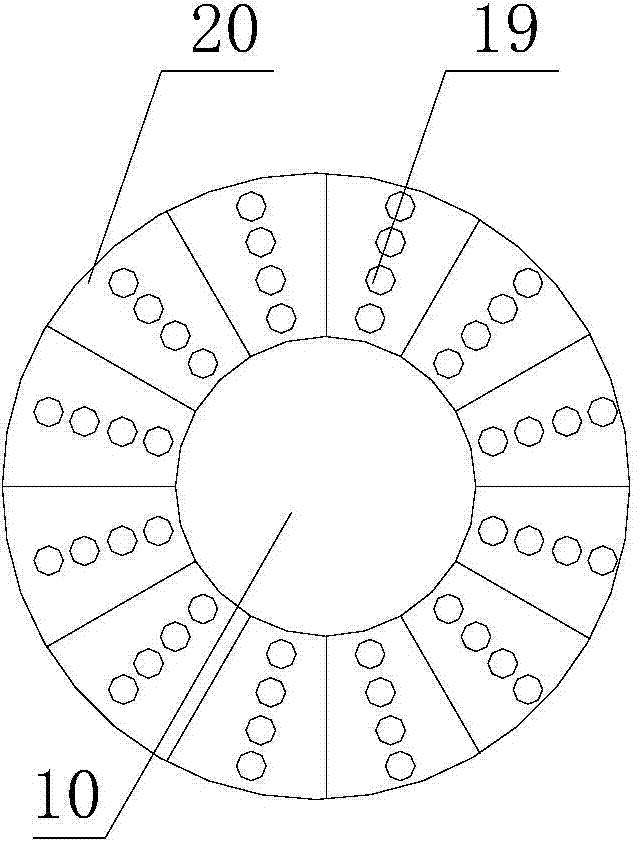

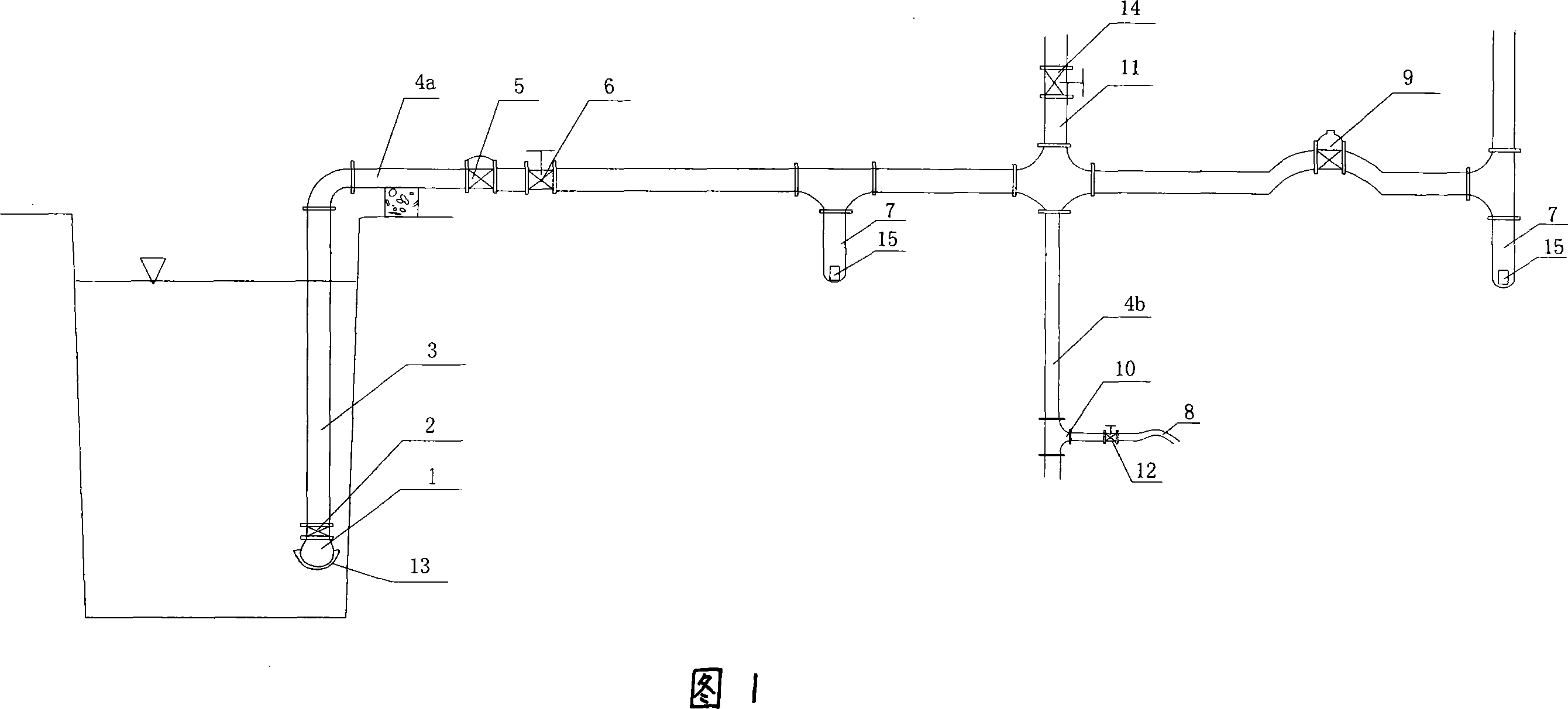

Biogas slurry pipeline fertilizing device

InactiveCN101238770AAvoid cloggingTimely air intakeLiquid fertiliser distributionWatering devicesExhaust valveControl valves

The invention relates to a biogas liquid pipeline fertilization device, which includes waste water disposal pump placed at the bottom part of the biogas liquid storage pool, the inverted valve which is placed above the immersed type waste water disposal pump, the liquid inlet tube which is connected to the inverted valve, the main tube which is connected to the liquid inlet tube, the fast pressure-relief valve and gate valve which are installed on the main tube, many branch tubes which are connected to the main tube, the water outlet pile which is connected to the main tube or the branch tube, the control valve which is fixed on the said water outlet pile, the soft tube which is connected to the water outlet pile, the deposit collecting tubes which are installed at the bottom part and the right angle corner of the main tube and branch tubes, the outlet valve which are installed on the said main tube and the branch tubes. The biogas liquid pipeline fertilization device can fertilize the field, which is good for environmental protection, and has the advantages of low cost and long lifespan.

Owner:熊棣文

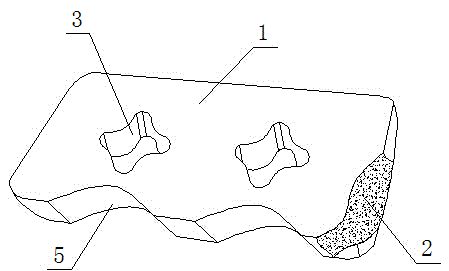

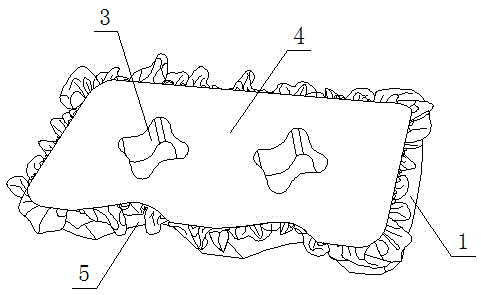

Bian-stone ear-receivable pillow

InactiveCN105231738AUnique and reasonable structureNice appearancePillowsMedical devicesAdditive ingredientMedicine

The invention relates to a pillow, in particular to a Bian-stone ear-receivable pillow which is composed of a pillow capsule and a filler. Ear-receivable grooves are formed in the pillow capsule which is filled with the filler, shoulder placement grooves are formed in one side of the pillow capsule, and the filler is composed of buckwheat hull, tea stem, Bian stone and various traditional Chinese medical healthcare ingredients. The Bian-stone ear-receivable pillow is unique and reasonable in structure and attractive in appearance and is made of comfortable fabric; when the Bian-stone ear-receivable pillow is in use, ears can be arranged in the ear-receivable grooves when a person is in a lateral position, auricular blood is circulated smoothly, and eardrums are stressed normally, so that people can enjoy healthy sleep; due to the shoulder placement grooves which are unique, shoulders can be arranged inside the shoulder placement grooves when the person lies on the side, and sleeping posture is more comfortable; different healthcare effects of maintaining health and refreshing, dredging meridians and collaterals and nourishing brain to stabilize sleeping can be realized, and a user acquires certain healthcare effect while enjoying comfortability.

Owner:陈英华

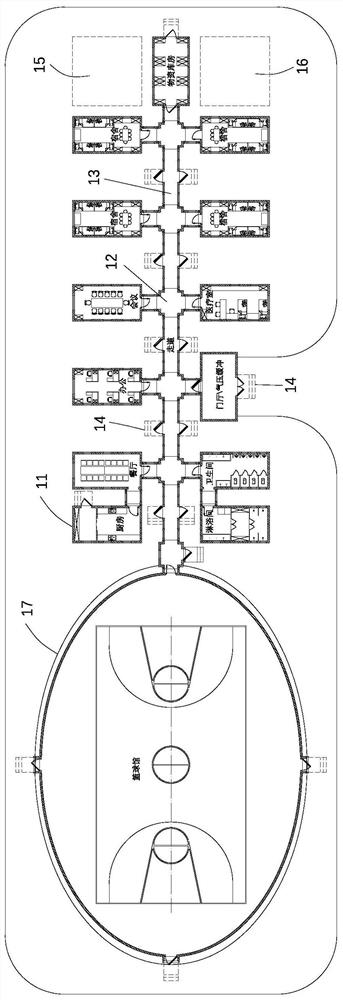

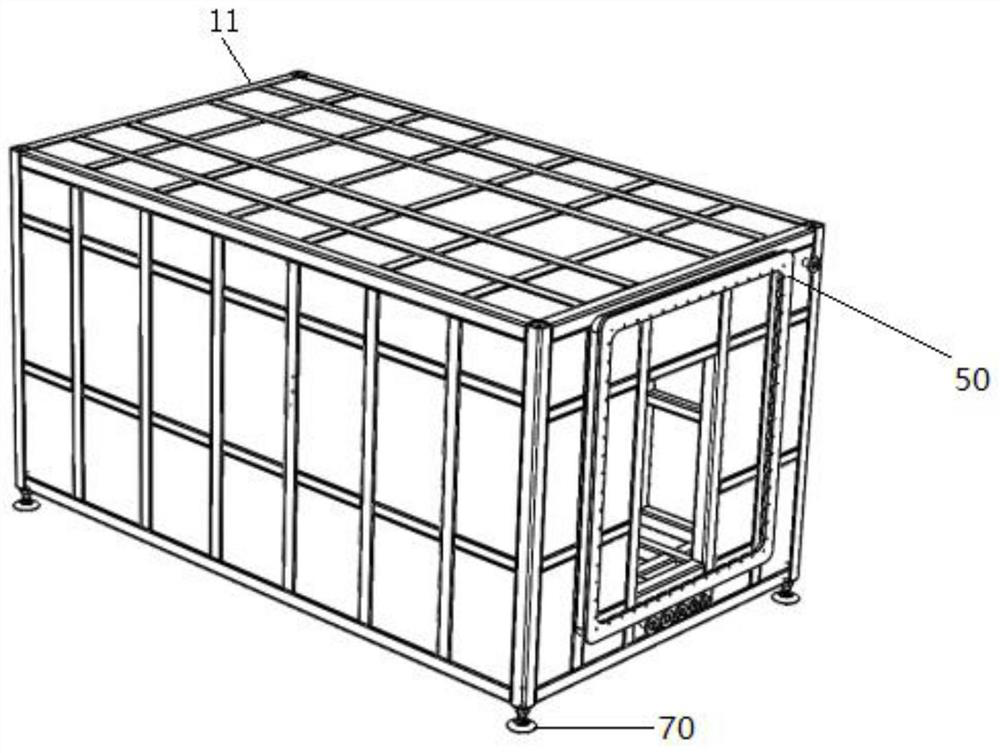

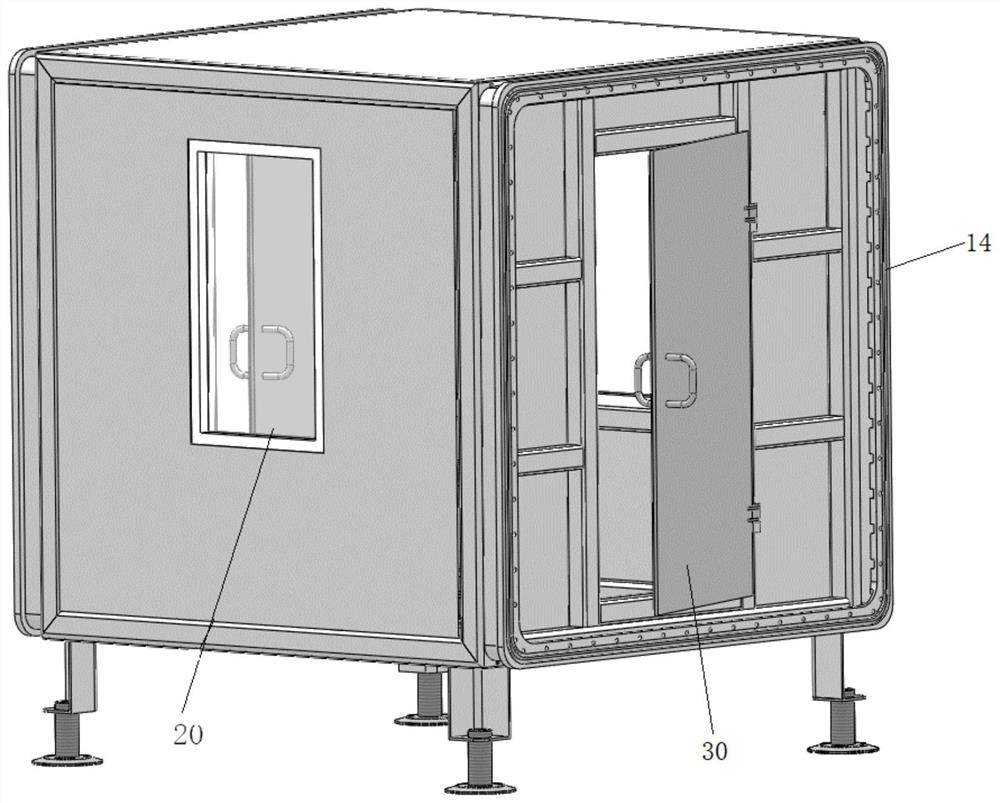

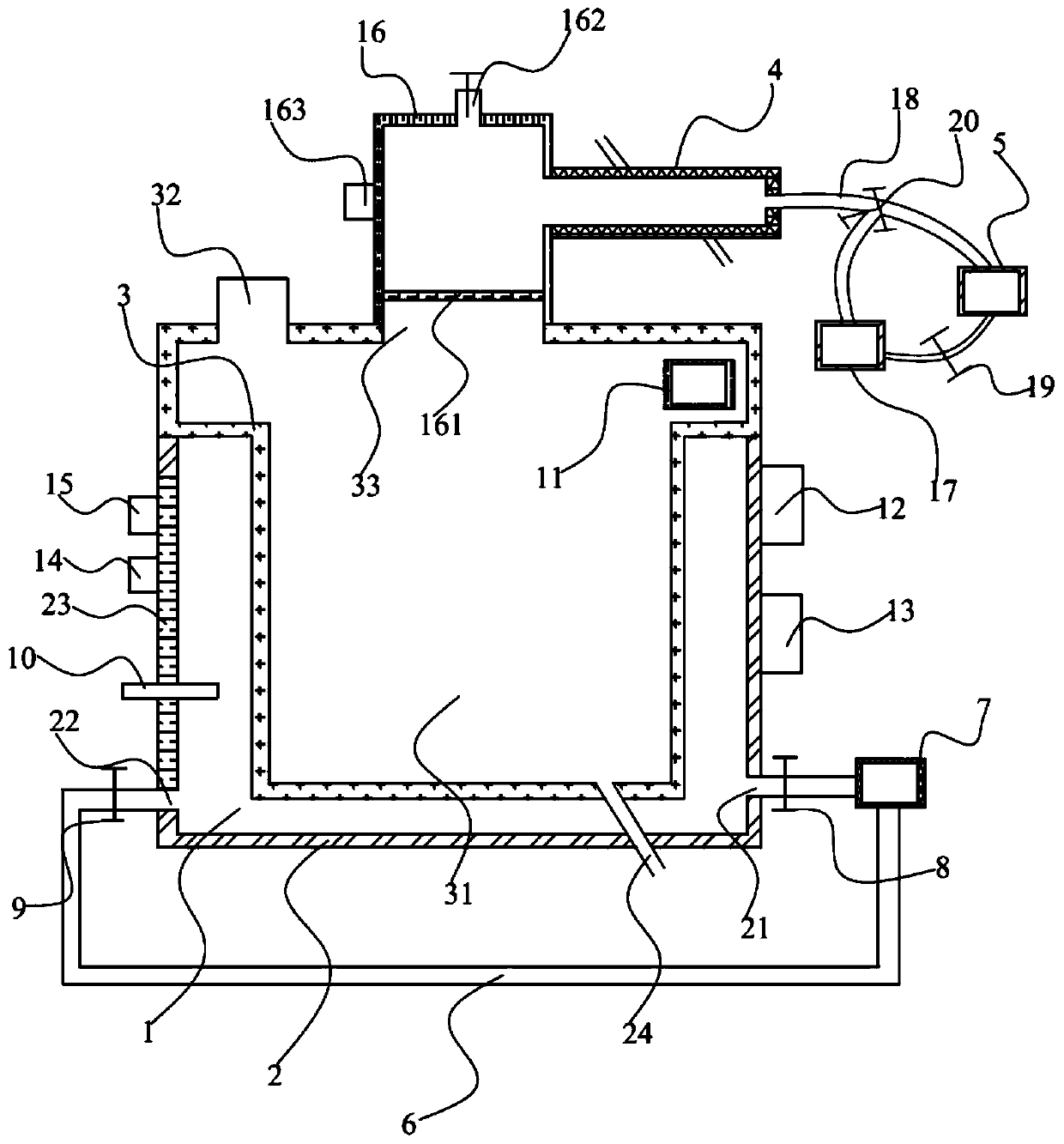

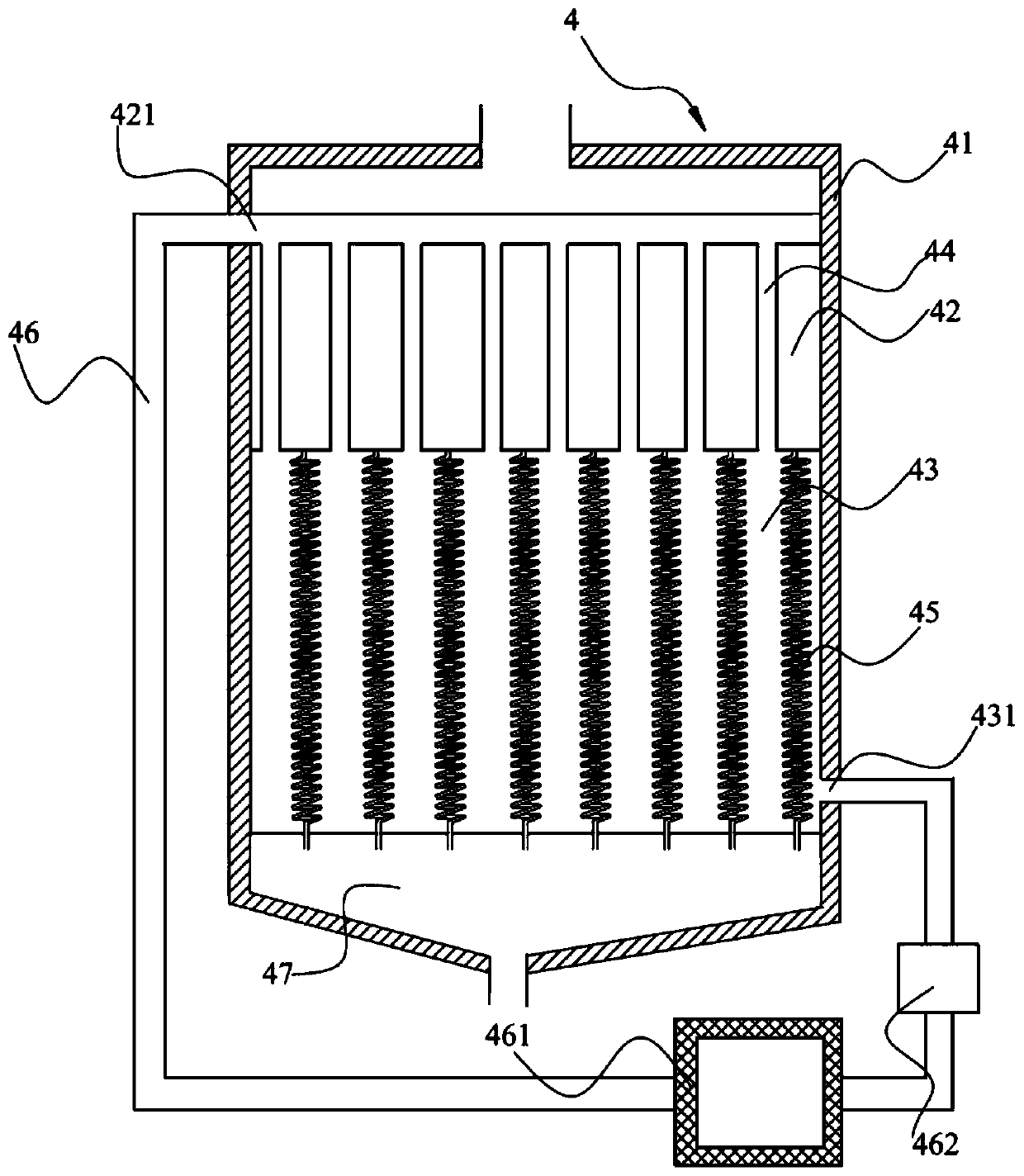

Pressurizing and oxygenating modular human residential building group in high-altitude area and using method of pressurizing and oxygenating modular human residential building group

PendingCN113775236AIncrease boost effectLarge space scaleHeat proofingWind energy generationArchitectural engineeringSewage

The invention relates to a pressurizing and oxygenating modular human residential building group in a high-altitude area. The group adopts modular design and comprises a plurality of standard cabins, a connecting node cabin, a connecting aisle cabin, a transition cabin, an equipment cabin, a sewage collecting cabin and large-span space module units, wherein the module units can be freely assembled in the plane direction and the vertical direction and can be freely expanded in function; the standard cabins are used for various functional scene requirements; the connecting node cabin and the connecting aisle cabin are used for space communication and personnel traffic between the standard cabins, between the standard cabins and the transition cabin and between the standard cabins and the large-span space; the transition cabin is used for building group indoor and outdoor pressure transition and personnel access; an intelligent pressurizing and oxygenating system is arranged in the equipment cabin; the sewage collecting cabin is used for collecting and treating sewage and waste in the building group; and the large-span space is used for meeting the requirements of large-scale meetings, large-scale gathering and sports of multiple groups of people. According to the invention, the design requirements of larger space scale, higher supercharging capacity, more living functions and lower-cost operation are met.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

Novel preparing method for scale inhibitor special for iron-pollution-resistant film

InactiveCN106145393AHigh hardnessHigh pHScale removal and water softeningTricarboxylic acidWater quality

The invention discloses a novel preparing method for a scale inhibitor special for an iron-pollution-resistant film, and relates to a preparing method for a film-special scale inhibiting-dispersing agent. The scale inhibitor is prepared from 10%-30% of polyepoxysuccinic acid (PESA), 10%-30% of 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), 5%-15% of an allyl sulfonic acid salt copolymer (AA / AMPS), 1%-5% of styrene sulfonic acid (SS), 2%-8% of hydrolytic polymaleic anhydride (HPMA) and the balance distilled water. According to the scale inhibitor, under the condition of high-alkali, high-hardness and high-pH-value water quality and existence of iron ions, calcium carbonate scale inhibition and calcium sulfate scale inhibition reach 100%, and the scale inhibition performance for silicon dioxide scale, barium sulfate scale, strontium sulfate scale and the like is improved.

Owner:中化化工科学技术研究总院有限公司

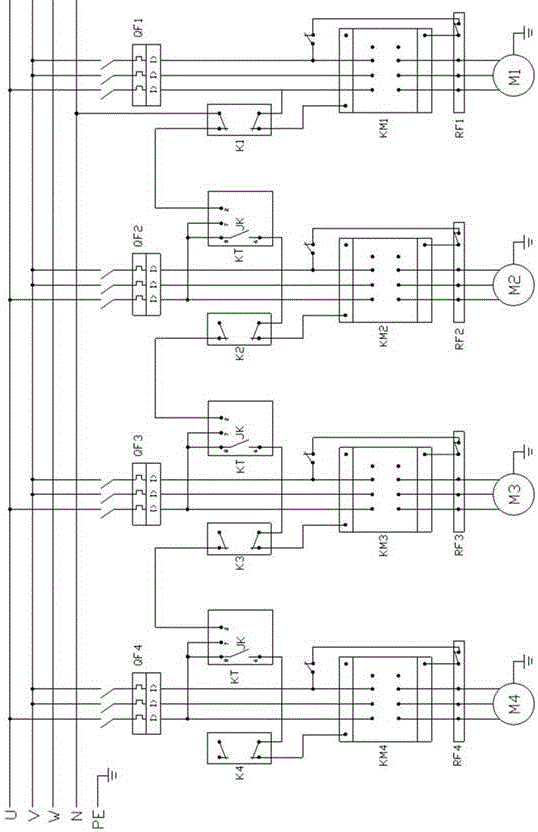

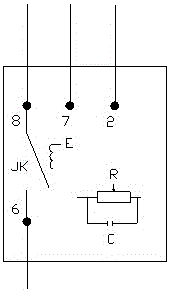

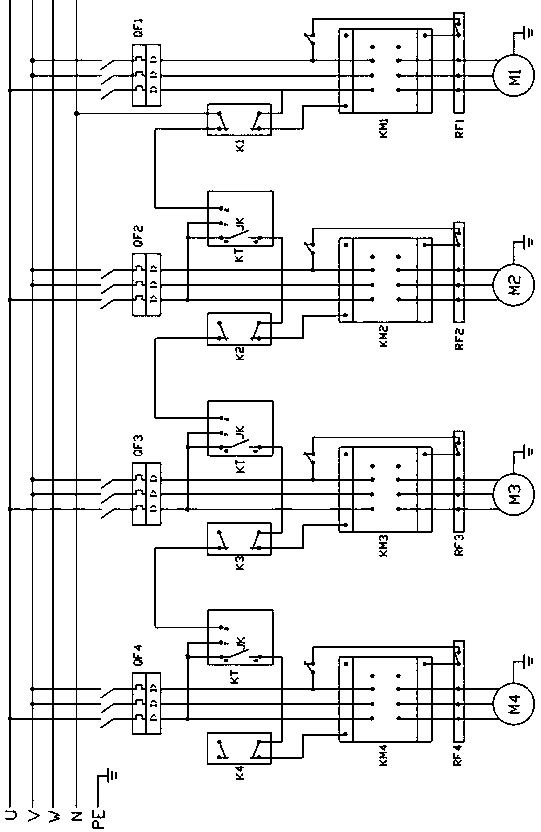

Air compressor electric control circuit for salt bag packing machine

ActiveCN105697349AReduce the impactReduce the temperaturePump controlPositive-displacement liquid enginesGas compressorEngineering

The invention relates to an air compressor electric control circuit for a salt bag packing machine. The air compressor electric control circuit for the salt bag packing machine comprises a plurality of air compressor circuit bodies which are sequentially connected with power leads. Each air compressor circuit body comprises an air switch QF connected with a power source and an alternating current contactor KM connected between the air switch QF and a motor M, and a safety resistor RF is connected between the alternating current contactor KM and the motor M. A time relay KT is arranged in each air compressor circuit body. A pressure switch K is arranged on each air compressor circuit body. The pressure switch K of the front air compressor circuit body is sequentially connected with the time relay KT of the back air compressor circuit body. The effect that an air compressor operates efficiently and orderly is ensured through the time relays KT and the pressure switches K which are arranged additionally.

Owner:中盐安徽润华强旺盐业有限公司

Power constant system capable of automatically adjusting electrode position and working method of power constant system

ActiveCN107682950AMelting power remains constantQuality improvementElectric discharge heatingIncreasing energy efficiencyConstant powerControl theory

The invention relates to a power constant system capable of automatically adjusting an electrode position and a working method of the power constant system. The system comprises a current transformer,an isolation transformer, a first rectifier, a second rectifier, a first sliding rheostat, a three-station three-way servo valve, a plunger cylinder, an oil return path and an oil injection path, wherein the current transformer is connected with an input end of the first rectifier, the isolation transformer is connected with an input end of the second rectifier, a first output end of the first rectifier is connected with a first output end of the second rectifier and a sliding end of the first sliding rheostat, a second output end of the first rectifier is connected with the first end of thefirst sliding rheostat and the servo valve, a second output end of the second rectifier is connected with a second end of the first sliding rheostat and the servo valve, and the plunger cylinder is connected with the oil return path and the oil injection path via the servo valve. Compared with the prior art, the system has the advantages that an idea of automatically adjusting the electrode position is employed, constant power of electric furnace smelting is achieved, and the smelting production quality and efficiency is greatly improved.

Owner:FUZHOU UNIV

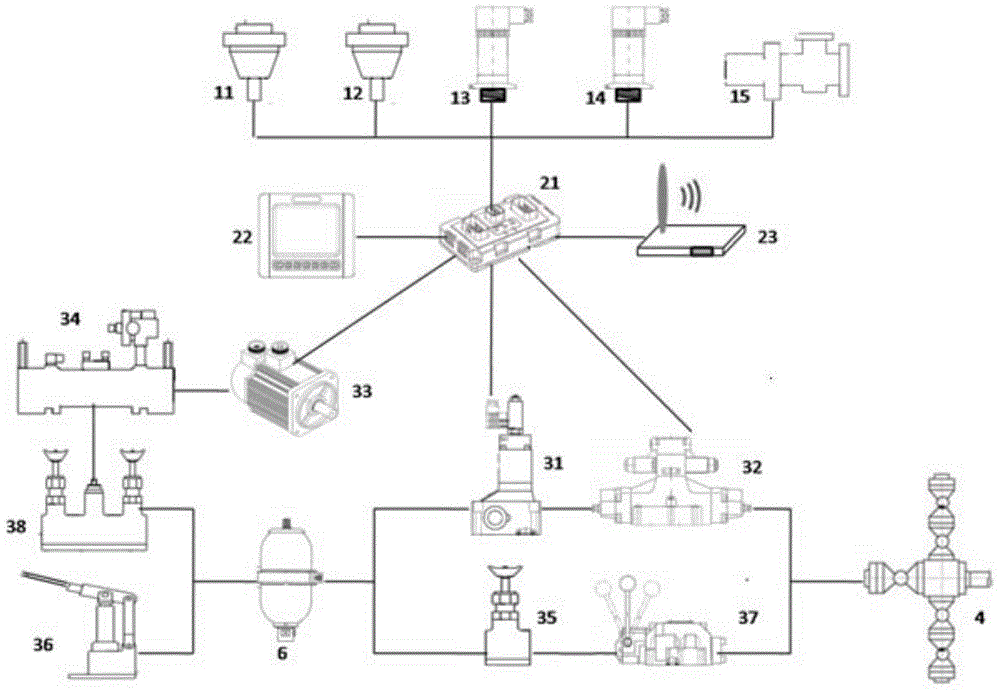

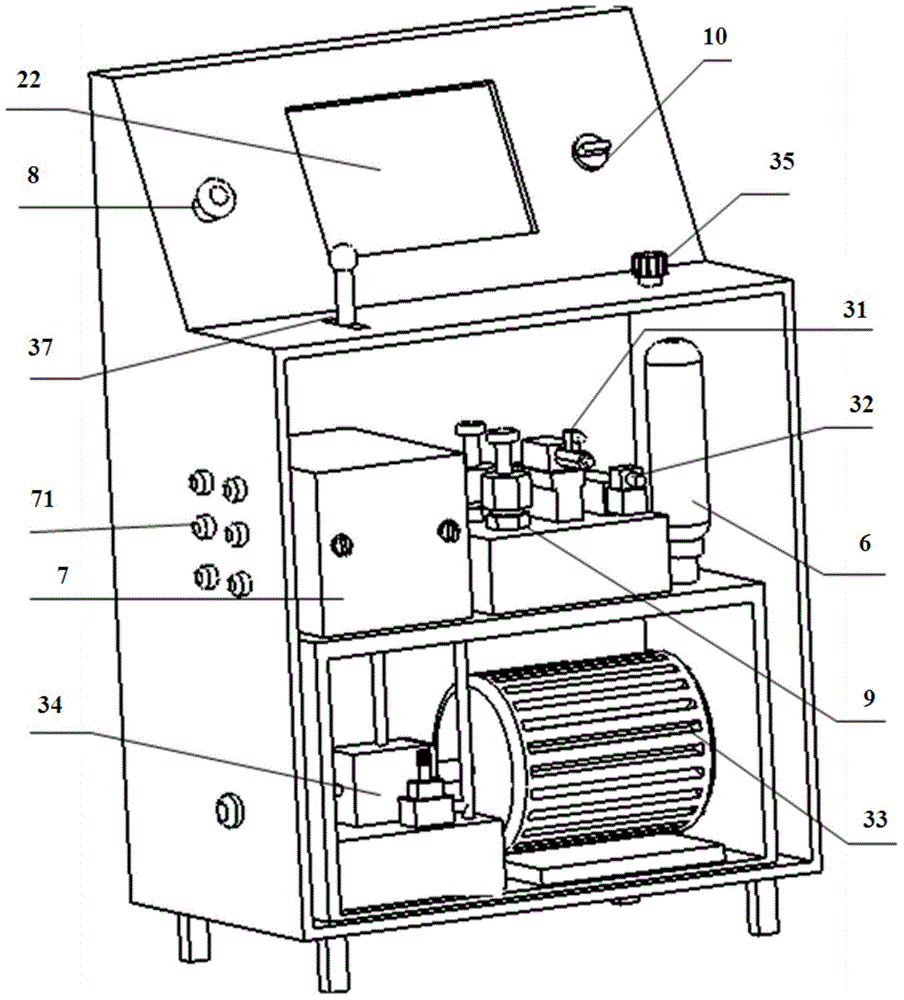

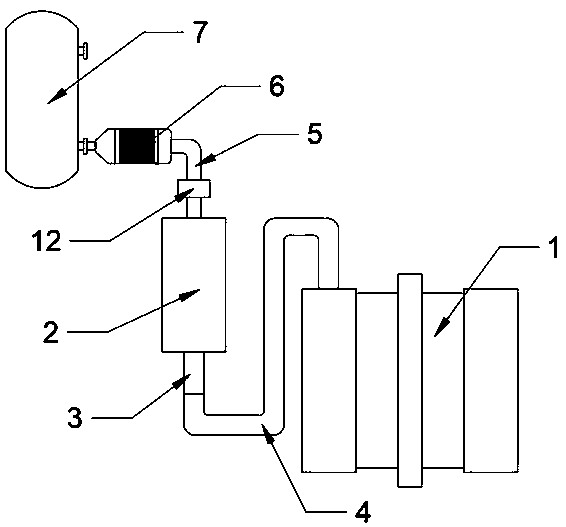

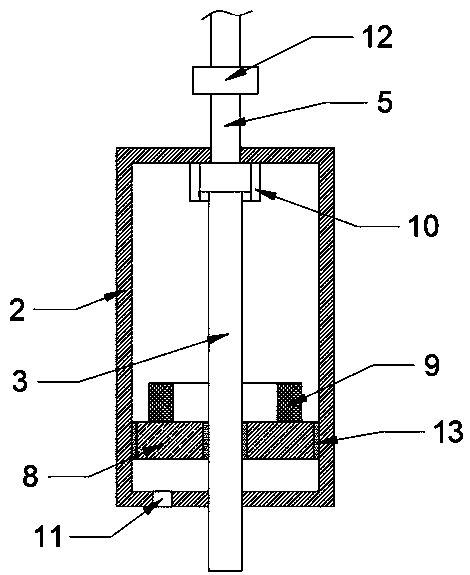

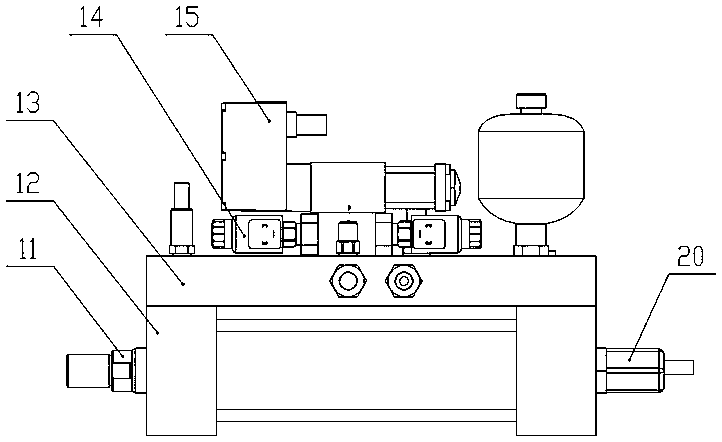

Automatic control device of choke manifold

InactiveCN105569591ARealize automatic controlImprove accuracyFlushingMagnetic exchangeAutomatic control

The invention relates to an automatic control device of a choke manifold. The control device comprises a sensor assembly, a display control assembly, and an execution assembly. The execution assembly comprises a proportional throttle valve, a magnetic exchange valve, a motor, a hydraulic pump, a combined valve block, and an energy accumulator. The input end of the display control assembly is connected with the sensor assembly, and the output end is connected with the proportional throttle valve, the magnetic exchange valve, and the motor. The motor is connected with the combined valve block through the hydraulic pump. The combined valve block is connected with the energy accumulator. The energy accumulator is connected with the choke manifold through the proportional throttle valve and the magnetic exchange valve in sequence. The display control assembly controls operation of the magnetic exchange valve, the proportional throttle valve, and the motor according to the data acquired by the sensor assembly, so as to realize control on the choke manifold. Compared with the prior art, the device is advantaged by automatic control, and stable control effect.

Owner:硕能(上海)自动化科技有限公司

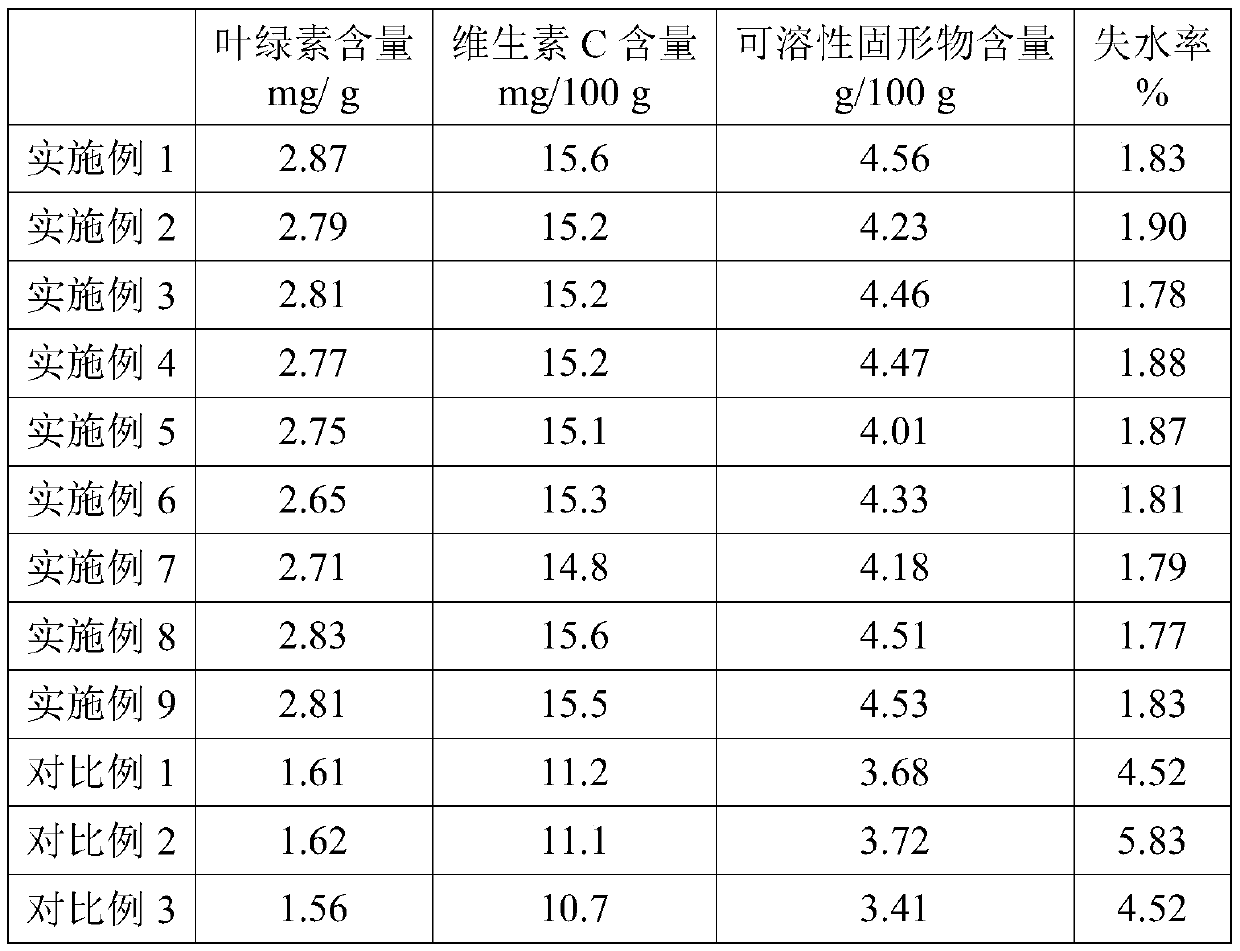

Vacuum precooling storage fresh keeping method of spinach

InactiveCN110269089ASpray evenlyReduce the temperatureSuperphosphatesFruits/vegetable preservation by irradiation/electric treatmentAdditive ingredientDistilled water

The invention discloses a vacuum precooling storage fresh keeping method of spinach. The method comprises the steps of firstly picking mature fresh spinach, washing away root soil, trimming the treated roots, removing withered, yellow and mashed leaves, performing ventilation to perform blow drying on the treated spinach so that no water drops exist on the surface of the spinach, and bundling the spinach of which the surface is air-dried with a rope; sprinkling distilled water to the spinach, rapidly putting the spinach to which the distilled water is sprinkled into vacuum precooling equipment, and enabling the spinach to be kept in the vacuum precooling equipment for 5-10min until the final temperature of the precooled spinach is 3-5 DEG C; sterilizing the vacuum precooled spinach through ultraviolet irradiation, and loading the sterilized spinach into PE opened fresh keeping bags; and finally putting the PE opened fresh keeping bags in a refrigerated cabinet of which the inner temperature is 3-5 DEG C, sprinkling nutrient solutions to spinach roots, completely charging mixed gas including ingredients of oxygen, carbon dioxide and inert gas or nitrogen into the refrigerated cabinet, and performing sealed preservation in the refrigerated cabinet. According to the vacuum precooling storage fresh keeping method disclosed by the invention, firstly the fresh-picked spinach is subjected to vacuum precooling and water replenishing treatment, and then the treated spinach is put in the refrigerated cabinet having definite condition for fresh keeping storage, so that the fresh keeping time of the spinach is successfully prolonged.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

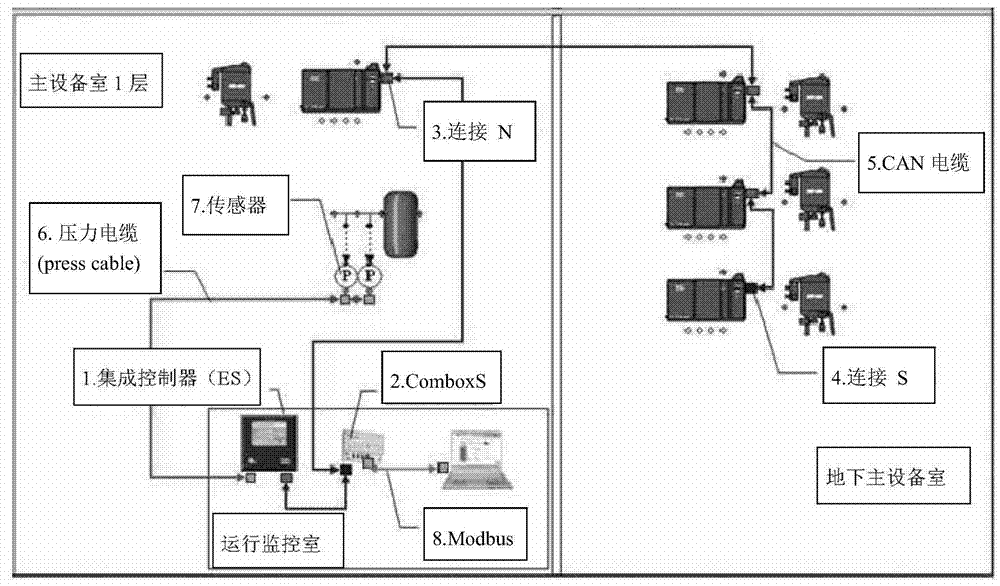

Multi control method for a plurality of air compressors

ActiveCN104295477AMeet usageRelieve pressureEngine fuctionsWorking fluid for enginesBasementGas compressor

The present invention relates to an integrated control operation method for multiple air compressors, wherein the method is capable of performing integrated control on the air compressors used in various industrial fields using one integrated controller, and more efficiently operating the air compressors. The present invention relates to the integrated control operation method for the air compressors, wherein the method comprises: a step of forming the air compressors including at least one variable speed drive (VSD) air compressor and normal air compressor; a step of mutually connecting the air compressors and the integrated controller with an RS-485 communication port so that the air compressors and the integrated controller communicate with each other, wherein the integrated controller is made up of air compressor control programs; a step of determining the reference value of working air pressure for a demander, and inputting and storing the reference value in the integrated controller; sequentially stopping the air compressors according to the order of priority, dropping the working air pressure, and recovering the working air pressure to the reference value when the working air pressure for the demander exceeds the reference value; and a step of recovering the working air pressure to the reference value by sequentially operating the stopped air compressors according to the order of priority when the working air pressure for the demander drops below the reference value. [Reference numerals] (1) Integrated controller (ES);(AA) First floor of a main machinery room;(BB) Operation monitoring room;(CC) Basement of a main machinery room

Owner:SP & G

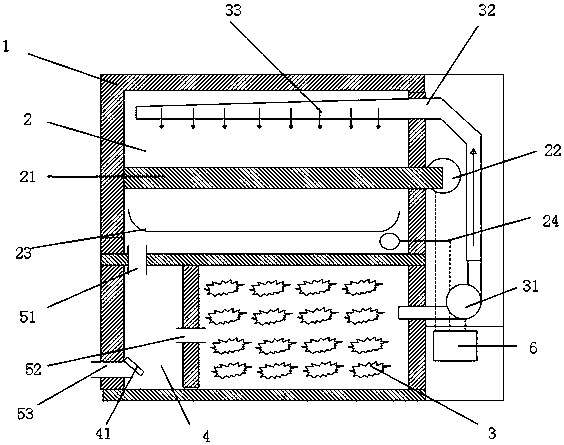

Smokeless full-automatic barbecue machine

InactiveCN108309072AHarmlessReduce grilling costsRoasting apparatusRoasters/grillsEngineeringSingle chip

The invention discloses a smokeless full-automatic barbecue machine which comprises a heat insulation area, a barbecue area, a heating area and a hot air recovery area. A furnace body of the smokelessfull-automatic barbecue machine is of a double-layer structure, the heat insulation area is arranged between the inner wall and the outer wall of the furnace body, the barbecue area is arranged at the top of the furnace body, and the heating area and the hot air recovery area are parallelly arranged at the bottom of the furnace body. An automatic rotating shaft is mounted in the middle of the barbecue area and connected with a rotating motor, a barbecue grill is fixed to the automatic rotating shaft, a tray is arranged below the automatic rotating shaft, a temperature sensor is mounted belowthe tray and electrically connected with a single chip microcomputer, a heat source is arranged in the heating area, and the heating area is communicated with the barbecue area sequentially through aninduced draft fan and an air supply pipe. According to the smokeless full-automatic barbecue machine, the whole barbecue process is smokeless, barbecue cost is saved, and barbecue food is healthy andharmless to the body of an eater.

Owner:慈溪市校杰电器有限公司

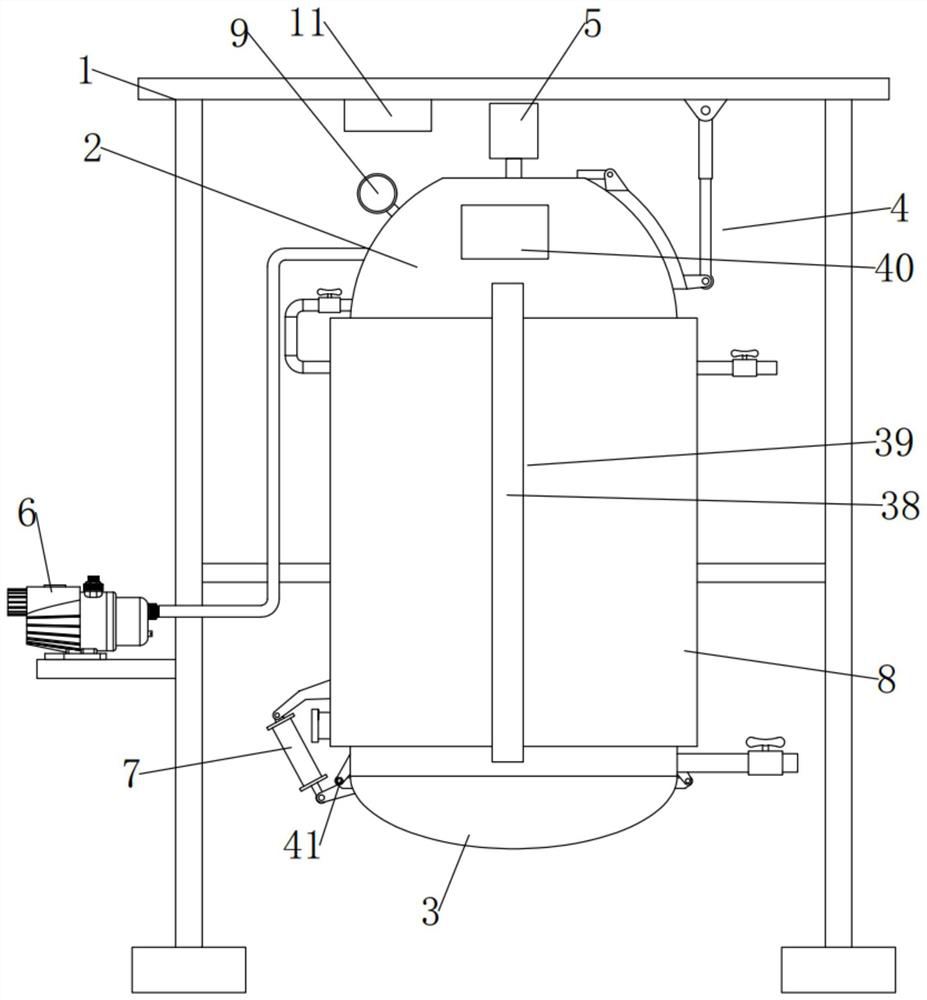

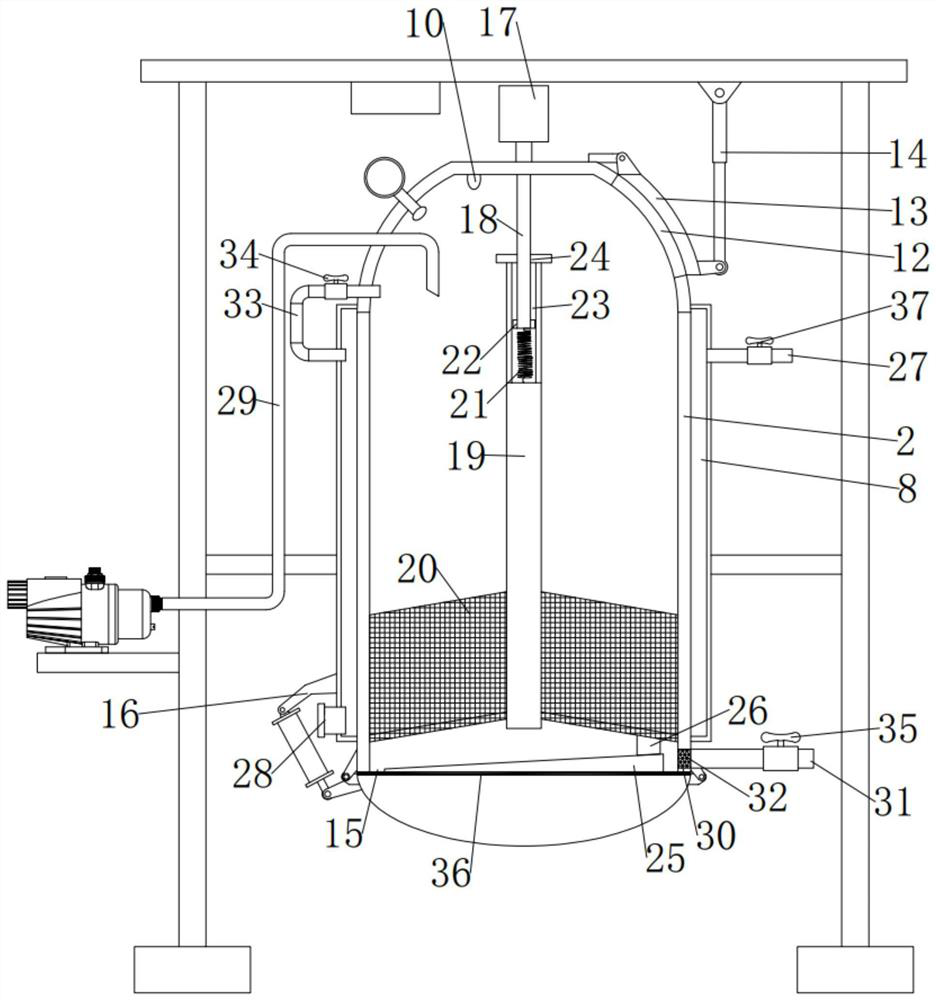

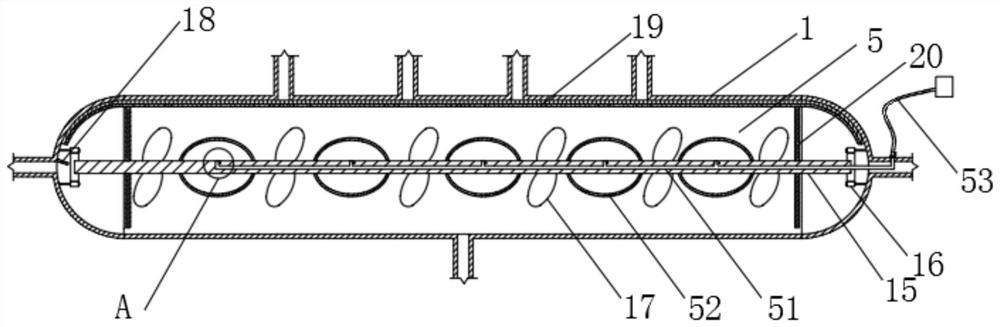

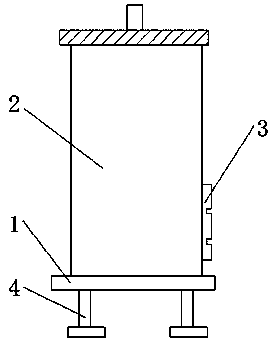

Dynamic extraction tank for extracting cannabidiol from industrial cannabis sativa

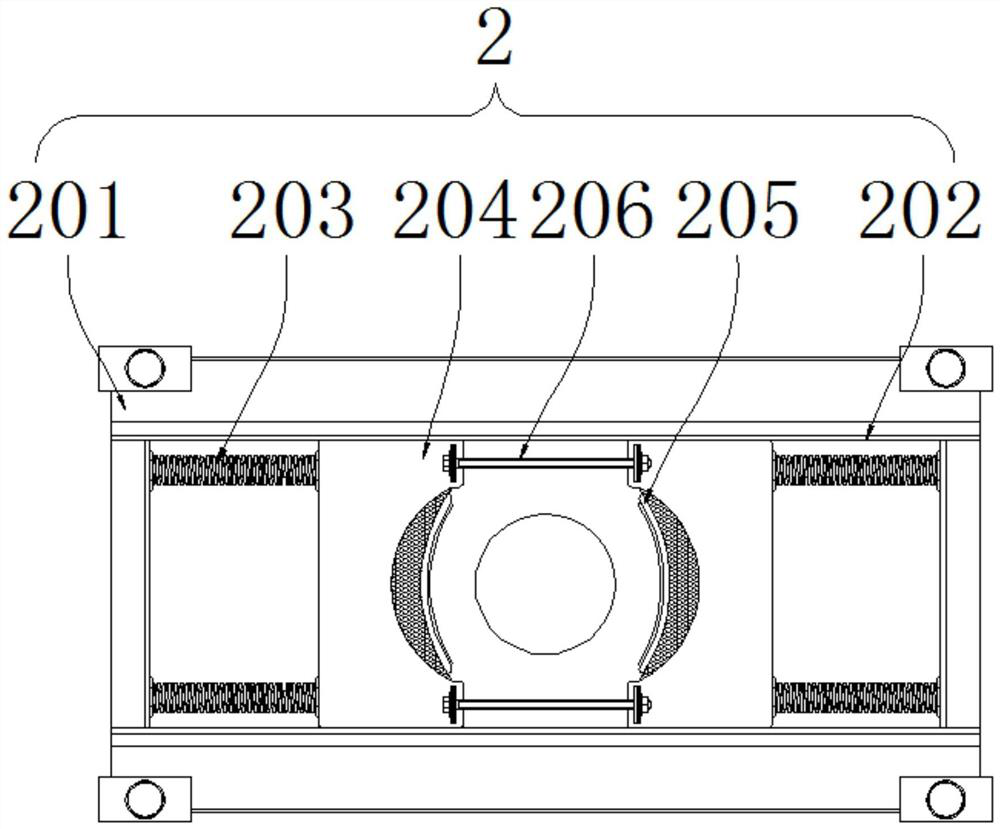

PendingCN112807741ASimple structureReasonable designSolid solvent extractionFiltration circuitsProcess engineeringStructural engineering

The invention discloses a dynamic extraction tank for extracting cannabidiol from industrial cannabis sativa, and the dynamic extraction tank comprises a fixing frame, a tank body, a bottom cover, a feeding assembly, a vibration type dynamic rotating device, a water pump, a deslagging lifting hydraulic rod, a heating cavity, a pressure gauge, a temperature sensor and a controller, the tank body is arranged on the fixing frame, a feeding port is formed in one side of the upper wall of the tank body, the feeding assembly is arranged at the feeding port and comprises a feeding door and a feeding lifting hydraulic rod, the feeding door is hinged to the feeding port, one end of the feeding lifting hydraulic rod is hinged to the fixing frame, the other end of the feeding lifting hydraulic rod is arranged on the feeding door, and the vibration type dynamic rotating device is arranged in the tank body; a slag outlet is formed in the lower wall of the tank body, and the bottom cover is hinged to the slag outlet. The invention belongs to the technical field of extraction and purification of plant components, and particularly provides a dynamic extraction tank for extracting cannabidiol from industrial cannabis sativa, which has the advantages of multidimensional dynamic extraction, convenience in deslagging and guarantee of uniform extraction of materials.

Owner:温州市金榜轻工机械有限公司

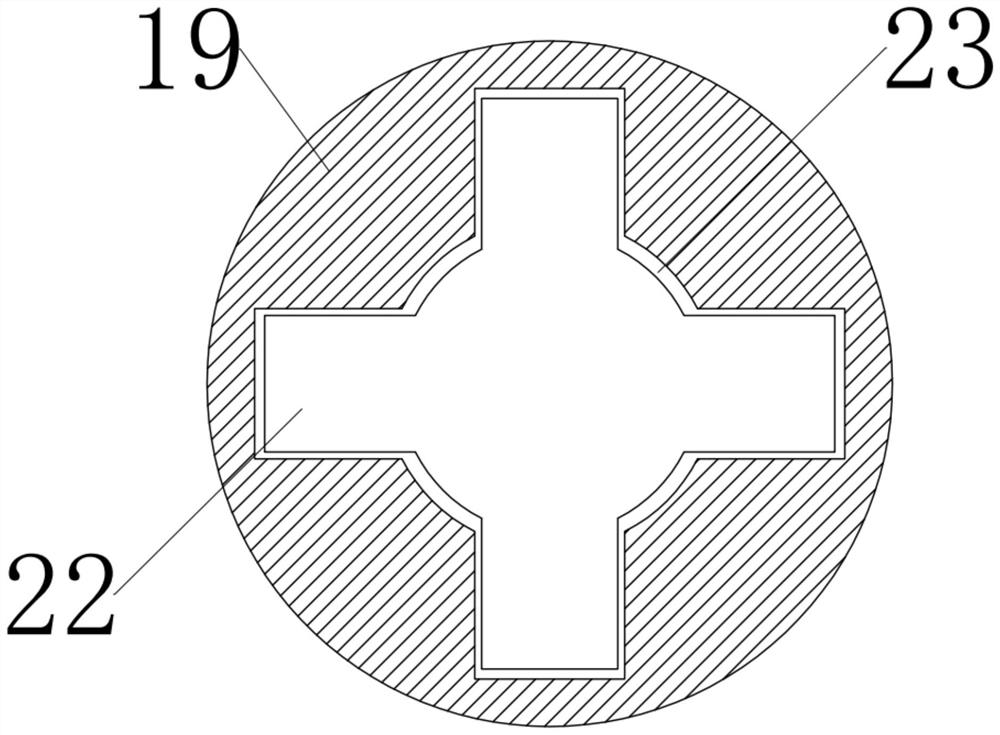

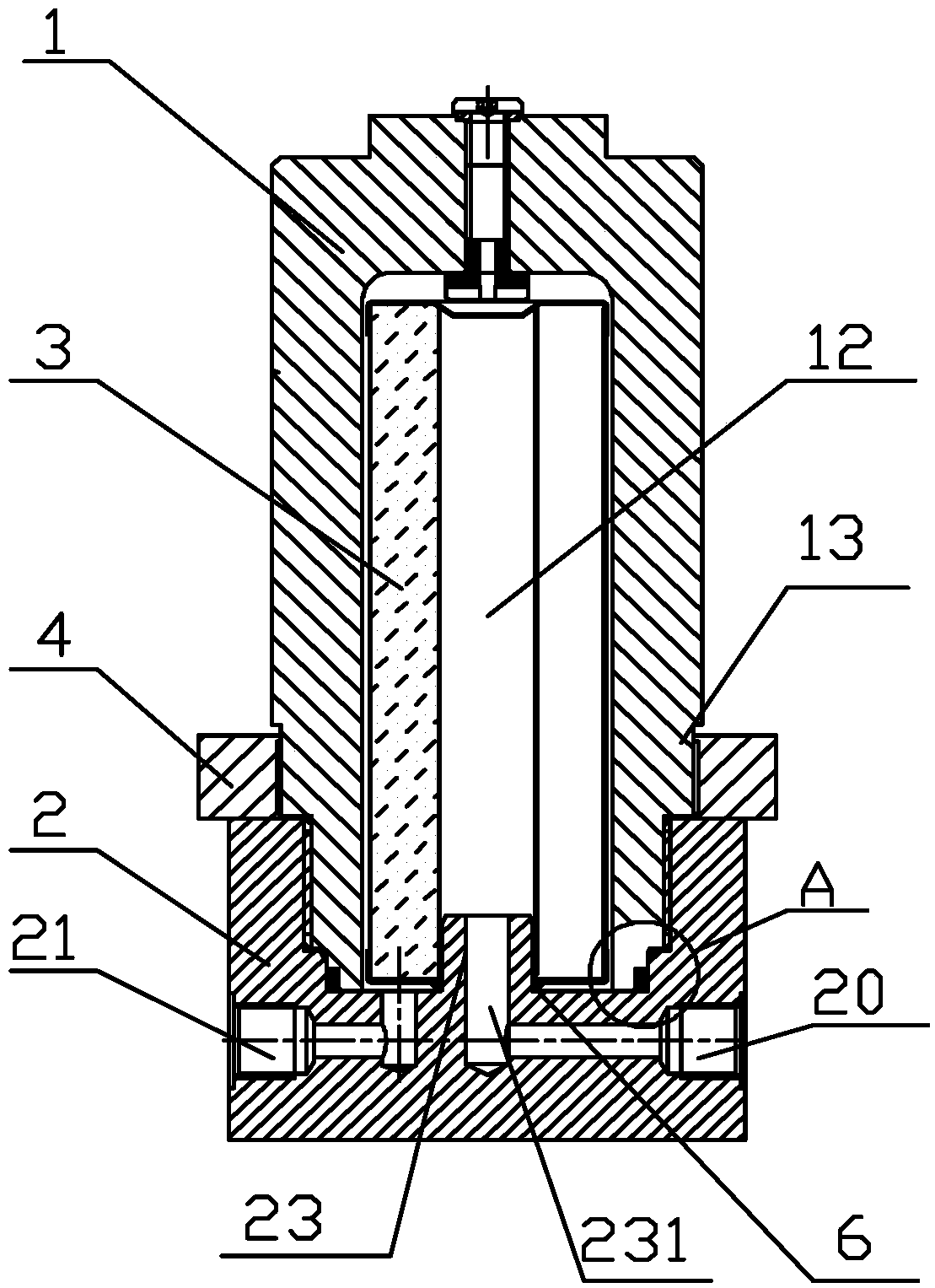

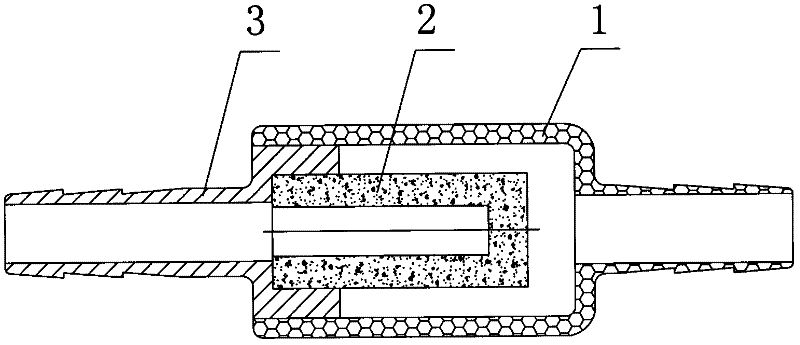

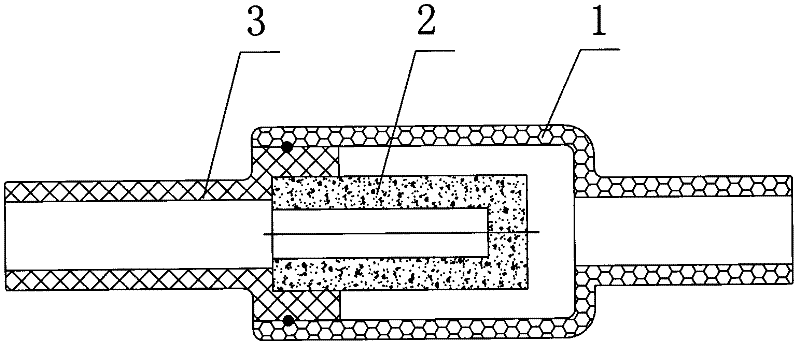

Multi-seal ultrahigh pressure oil way filter

InactiveCN108105209ANormal pressureImprove sealingFluid-pressure actuator componentsUltra high pressureHigh pressure

The invention discloses a multi-seal ultrahigh pressure oil way filter. The multi-seal ultrahigh pressure oil way filter includes a filtering barrel, a filter seat, and a filter element; an oil inletand an oil outlet are formed in the filter seat; the filtering barrel and the filter seat are fixed through thread connection; a step is arranged on a lower part of the filtering barrel; a sealed circular space is formed by the step and an inner side wall and a bottom wall of the filter seat; a hole sliding ring type seal combination is arranged in the circular space; the oil inlet communicates with an oil cavity; a filter element is embedded between an inner wall of the filtering barrel and an outer wall of the oil cavity; the oil outlet communicates with the filter element; a hump extendingupward and adapting to the oil cavity is arranged in the filter seat; the hump stretches into the oil cavity; and an O-shaped seal ring is arranged on a contact part between the filter element and thehump and the inner bottom wall of the filter seat. The step and the combined seal manner can improve the seal effect between the filtering barrel and the filter seat, and can effectively ensure thatoil leakage and pressure relief can be prevented while high pressure oil is in the filter.

Owner:重庆键英液压机电有限公司

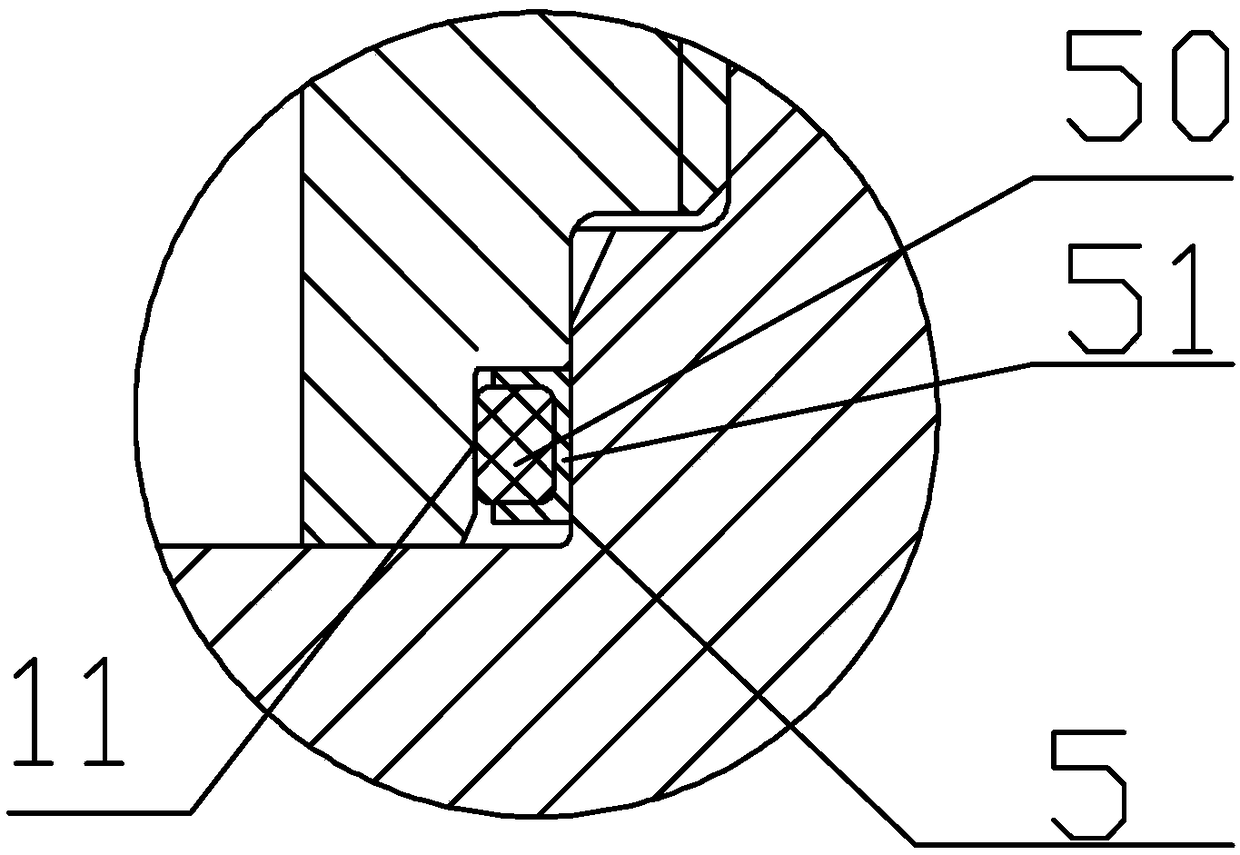

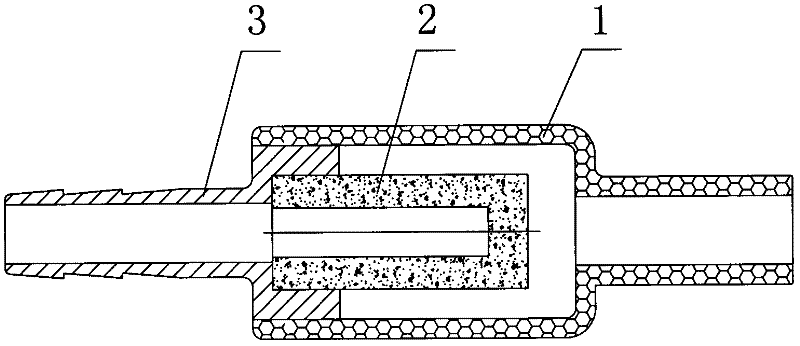

Disposal medical negative pressure gas joint backflow prevention device

ActiveCN102500054AStable flowNo backflow phenomenonSuction devicesValvesBackflow prevention deviceBottle

The invention discloses a disposal medical negative pressure gas joint backflow prevention device which comprises a negative pressure gas joint (4), a liquid collecting bottle (9) and a backflow prevention device (6), wherein the outlet end and the inlet end of the backflow prevention device are respectively connected and conducted with the negative pressure gas joint and the liquid collecting bottle; the backflow prevention device further comprises a hollow integrated outer casing (1) with an inlet joint integrated structure, an outlet joint (3) with an opened inlet end part inner cavity concave platform structure and a sealing filter element (2) for embedding and connecting the inlet end part notch of the outlet joint and sealing pores; and the sealing filter element is a honeycomb pinhole structure with a built-in center concave hole structure, and the shape of the center concave hole is matched with that of the filter element body. The disposal medical negative pressure gas joint backflow prevention device disclosed by the invention has the characteristics of simple structure, convenience for assembly, capability of quickly sealing and blocking and the like, and can satisfy the requirements of backflow prevention control of the negative pressure gas joint.

Owner:HUNAN TAIYANGLONG MEDICAL TECH

Distiller and distillation device

ActiveCN110129172AEasy to put inFully heatedAlcoholic beverage preparationGeneration rateDistillation

The invention provides a distiller and a distillation device. The distiller comprises an inner cylinder and an outer cylinder; the interior of the inner cylinder is formed with an accommodating chamber suitable for accommodating fermented grains, and the inner cylinder is provided with a feed port and a discharge port which communicate with the accommodating chamber; the outer cylinder is providedwith a heat medium inlet, the inner cylinder is arranged in the outer cylinder, a flowing chamber is formed between the inner cylinder and the outer cylinder, and a flowing chamber coats the exteriorof the circumference wall and the bottom wall of the inner cylinder; the heat medium inlet communicates with the flowing chamber and a hot source suitable for supplying a heat medium, and the heat medium in a fluid form enters the flowing chamber from the heat medium inlet, so as to heat the fermented grains in the inner cylinder to evaporate into wine steam. The distiller can make the fermentedgrains in the inner cylinder heated more evenly, the fermented grains are evaporated fully, and the wine generation rate of the fermented grains is improved.

Owner:INST OF AGRI PROD QUALITY SAFETY & STANDARD JIANGXI ACAD OF AGRI SCI

Soil gas flux measuring instrument and its measuring method

ActiveCN103235105BUndisturbedNot easy to interfereEarth material testingObservational errorMeasuring instrument

The invention relates to a soil gas flux detector comprising a soil ring (1), supporting legs (2), a pedestal (20), a gas chamber (7), a protective cover (8), a line passing shaft (9), and a control box (19). The flux detector is characterized in that a sealing ring (5) and a pressing ring (3) are arranged above the pedestal (20); the supporting legs (2) are arranged below the pedestal (20); supporting led slide grooves (16) and supporting leg rotation shafts (14) are arranged on the supporting legs (2); a buffering device (8-7) is arranged in the gas chamber (7), the protective cover (8), and the line passing shaft (9); and a return button (19-4) is arranged on the control box (19). With the device provided by the invention, problems such as exposed gas pipe and line, gas chamber offset, and large measuring error of soil gas flux detector can be solved.

Owner:北京萨维福特科技有限公司

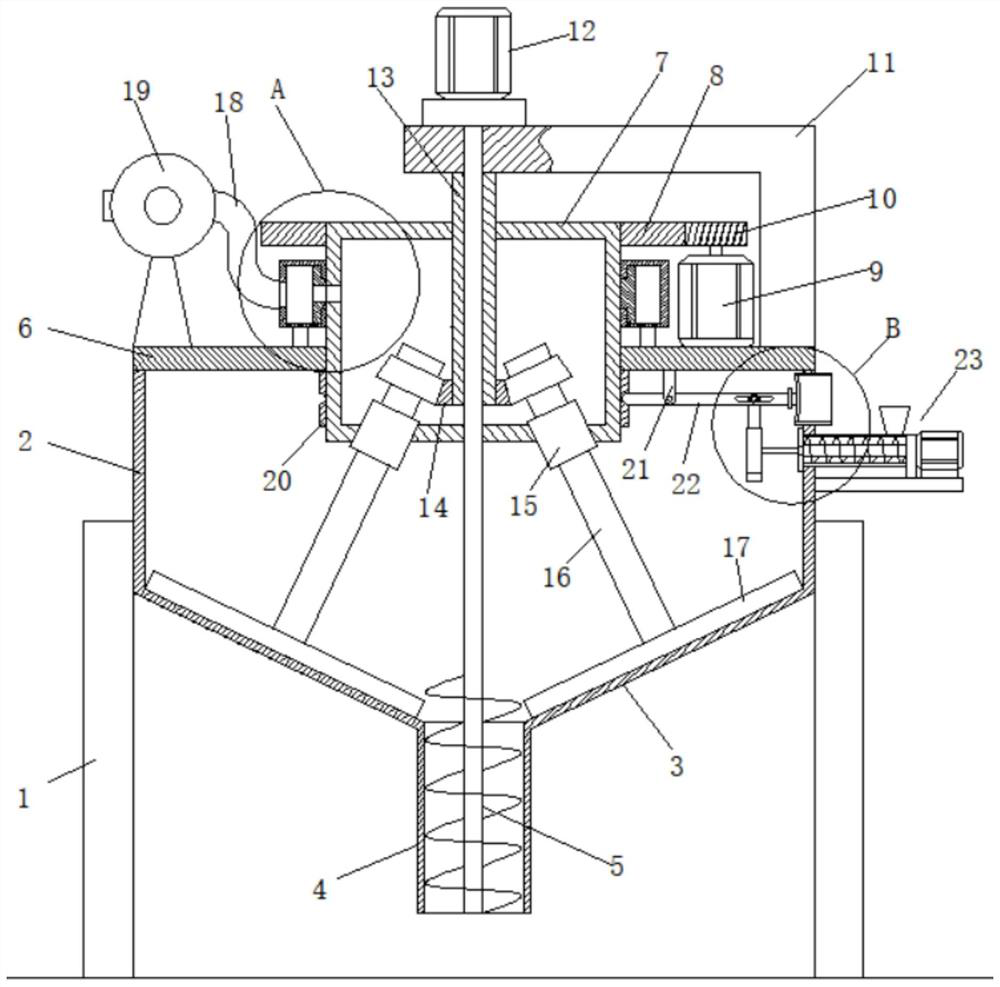

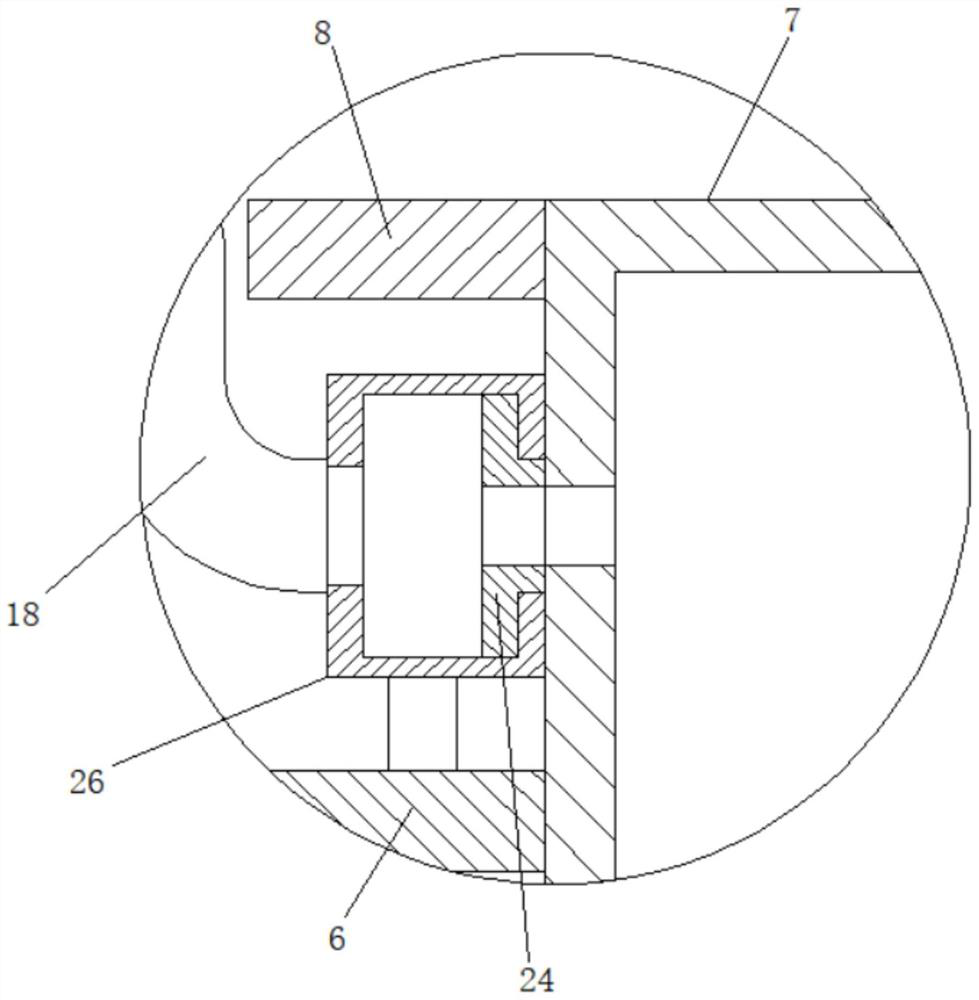

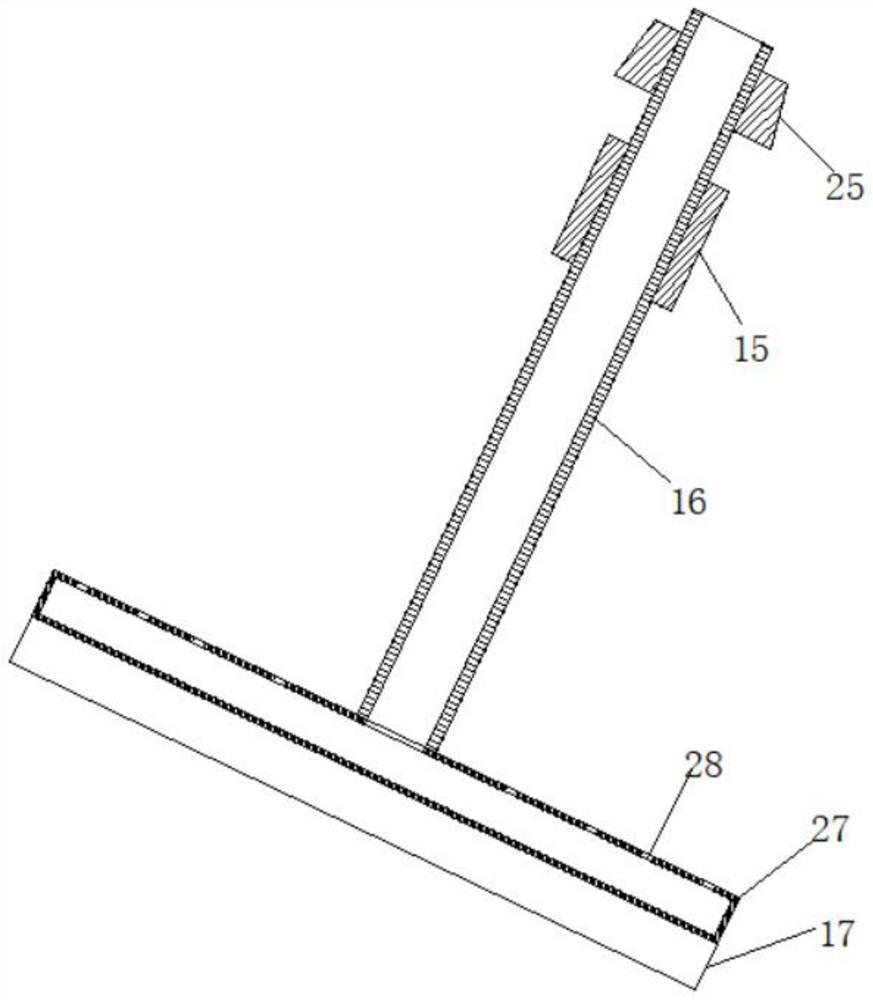

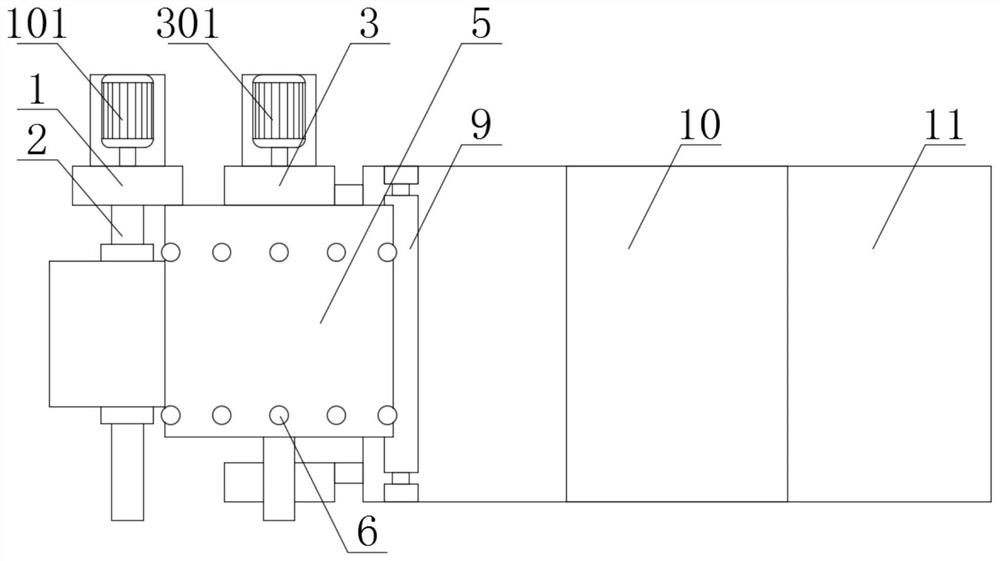

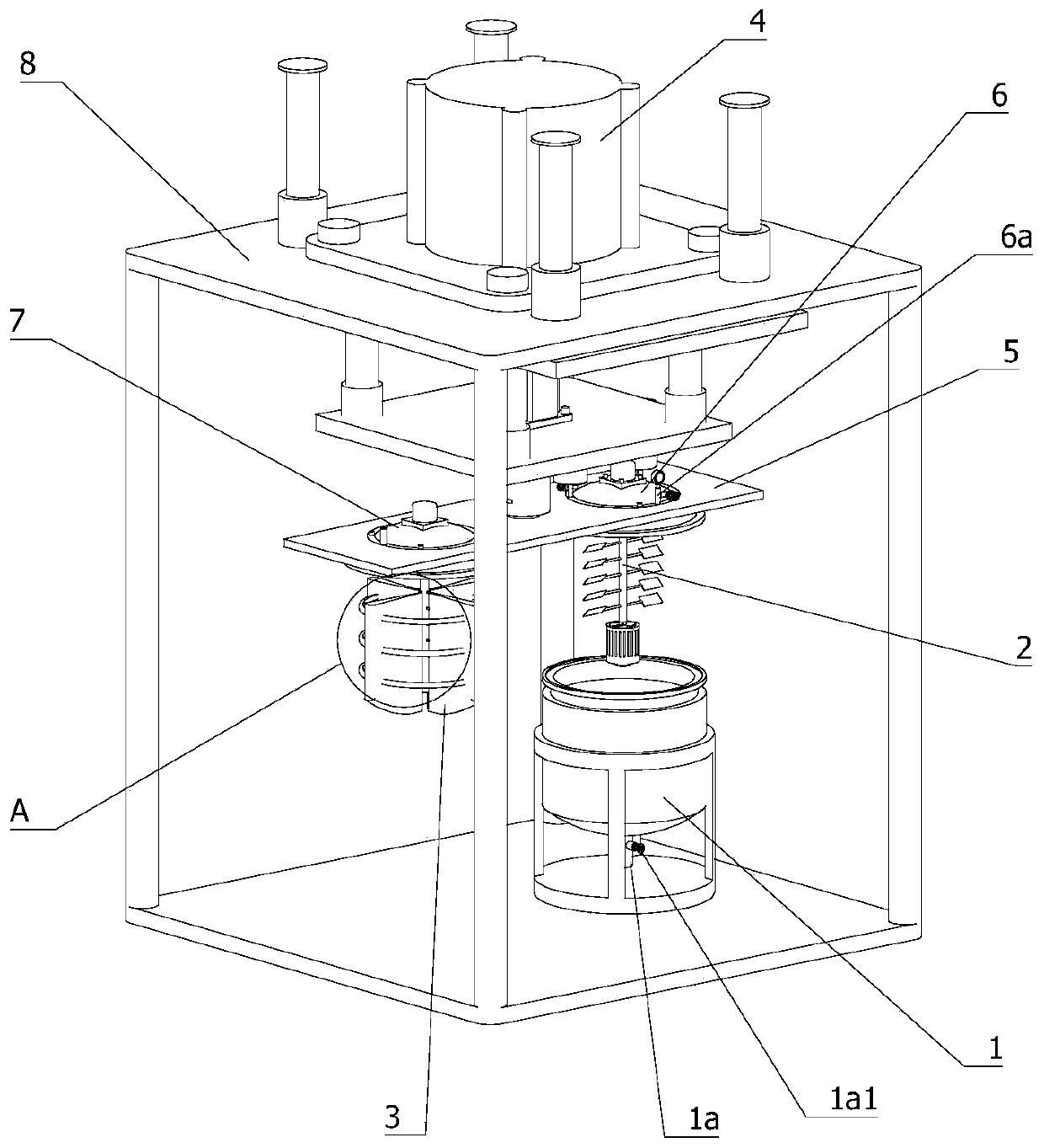

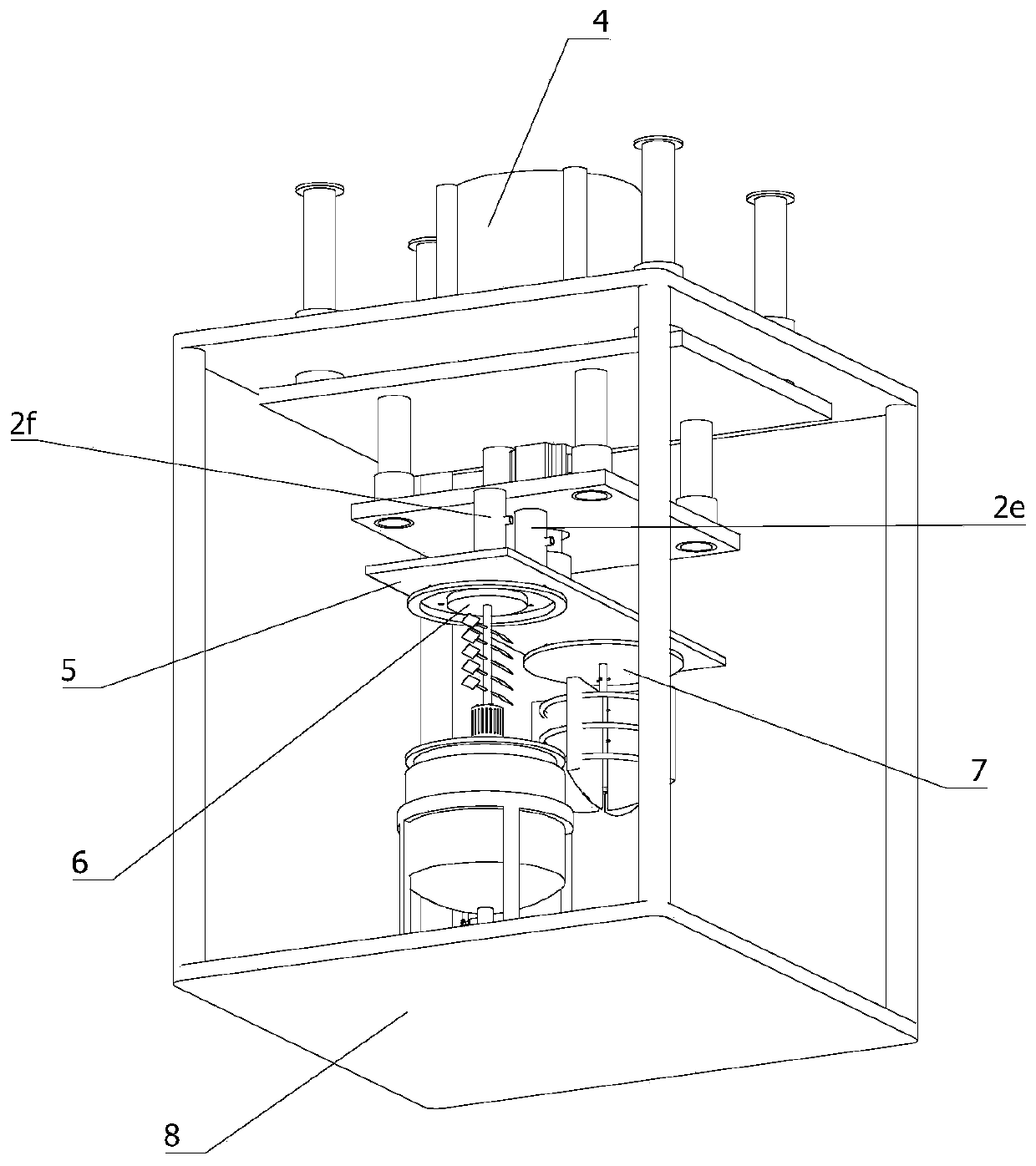

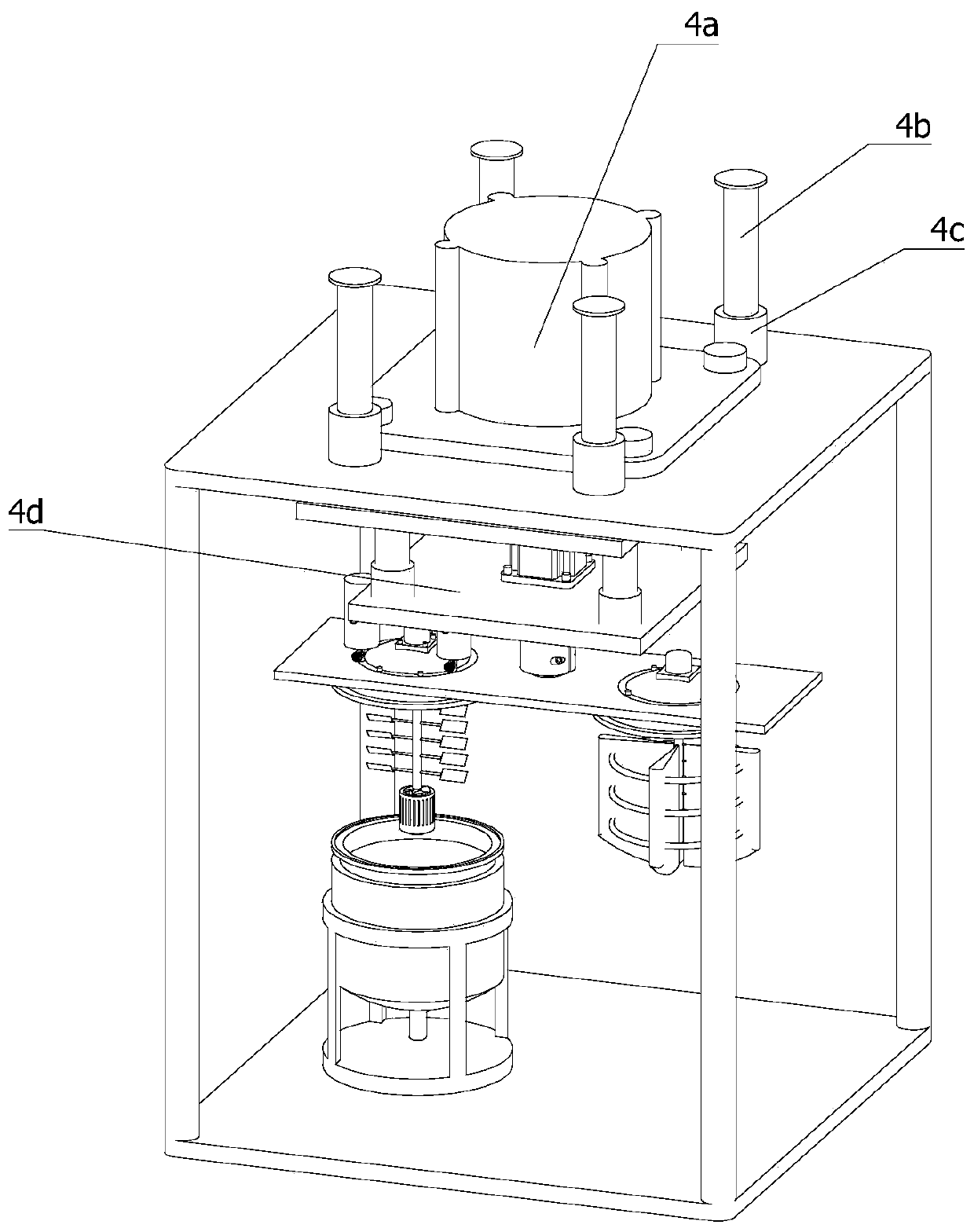

Stirrer for full-automatic powder packaging and using method thereof

PendingCN112717752AStir wellGood turning effectRotary stirring mixersTransportation and packagingIndustrial engineeringFully automated

The invention relates to the field of powder packaging machines, in particular to a stirrer for full-automatic powder packaging and a using method thereof. The stirrer for full-automatic powder packaging comprises a rack and a storage barrel fixed to the rack, wherein the storage barrel is provided with a stirring mechanism used for stirring powder in the storage barrel; the side wall of the storage barrel is provided with an exhaust assembly used for exhausting and decompressing gas generated when the stirring mechanism works; a powder cleaning mechanism used for cleaning an exhausting assembly is arranged in the storage barrel; the stirring mechanism is in transmission connection with the powder cleaning mechanism; a spiral feeder used for conveying powder products into the storage barrel is connected to the side wall of the storage barrel; a scattering mechanism used for scattering the powder products conveyed by the spiral feeder is arranged on the inner side wall of the storage barrel; and the powder cleaning mechanism is in transmission connection with the scattering mechanism. According to the stirrer for full-automatic powder packaging and the using method thereof, it is ensured that filling quality is uniform during packaging with packaging bags, time and labor are saved, labor intensity is reduced, and production efficiency is improved.

Owner:林盛强

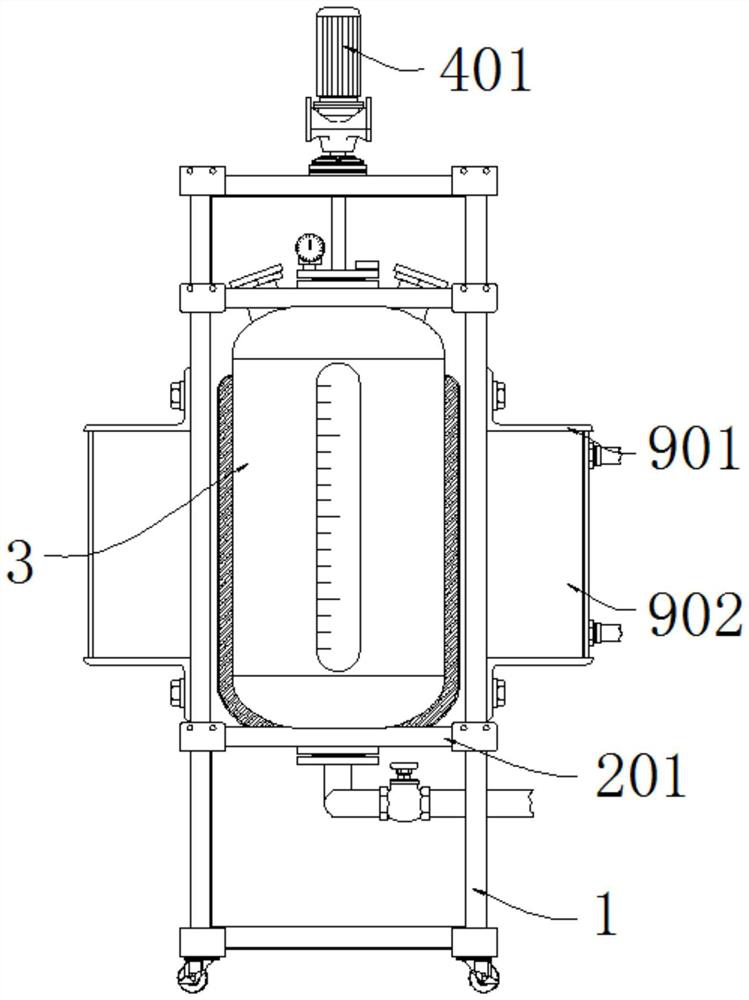

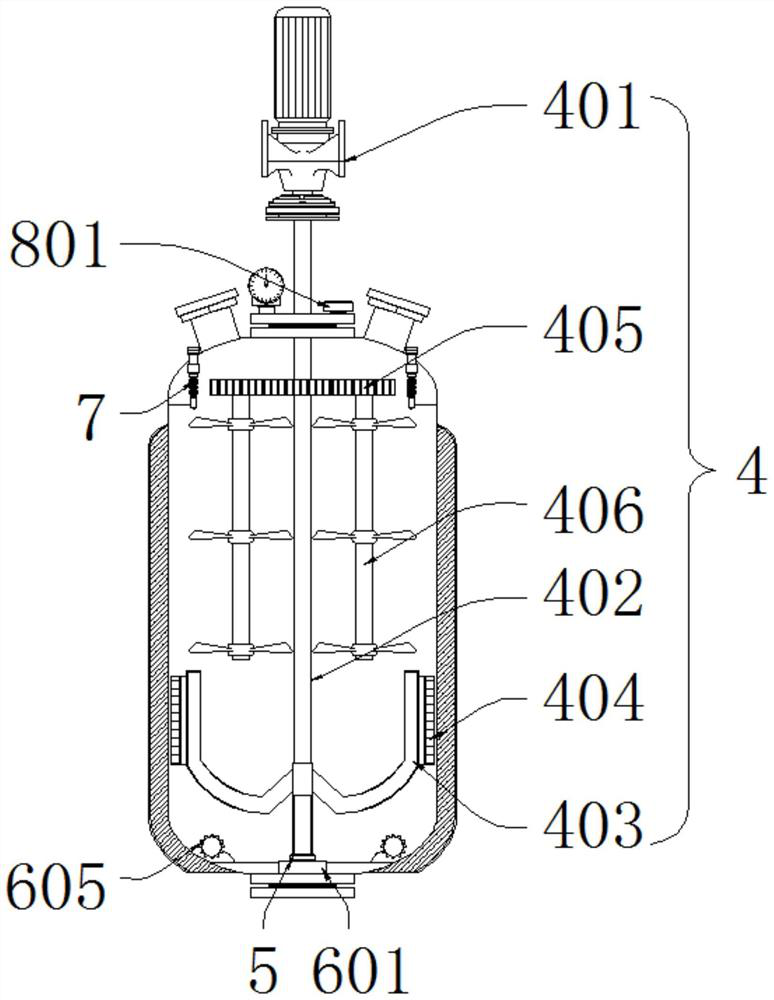

Culture kettle with temperature control structure for bio-based material production

InactiveCN114367238AMonitor temperature changesAvoid situations where deposits are difficult to cleanTransportation and packagingMixer accessoriesTemperature controlProcess engineering

The invention discloses a culture kettle with a temperature control structure for bio-based material production, and relates to the technical field of bio-based material production, the culture kettle comprises an external frame and an anti-precipitation assembly, the external frame is internally provided with an auxiliary assembly, the auxiliary assembly is internally provided with a kettle body, the kettle body is internally provided with a stirring assembly, and the stirring assembly is internally provided with an anti-precipitation assembly; the stirring assembly comprises a servo motor, a stirring shaft, stirring blades, a scraping plate, a gear set and an auxiliary shaft. According to the invention, through mutual cooperation of a plurality of components, raw materials in the culture kettle can be fully mixed, the inner wall and the bottom of the kettle body can be cleaned during mixing, the situation that precipitates appear at the bottom and are difficult to clean after long-time use is avoided, and the temperature change in the kettle body can be monitored, so that the operation is convenient. And when the temperature difference is too high, the interior can be heated, the normal internal pressure during heating can be ensured through cooperation with the pressure relief assembly, and the stability in work is improved.

Owner:江苏辰安泰生物医药研究院有限公司

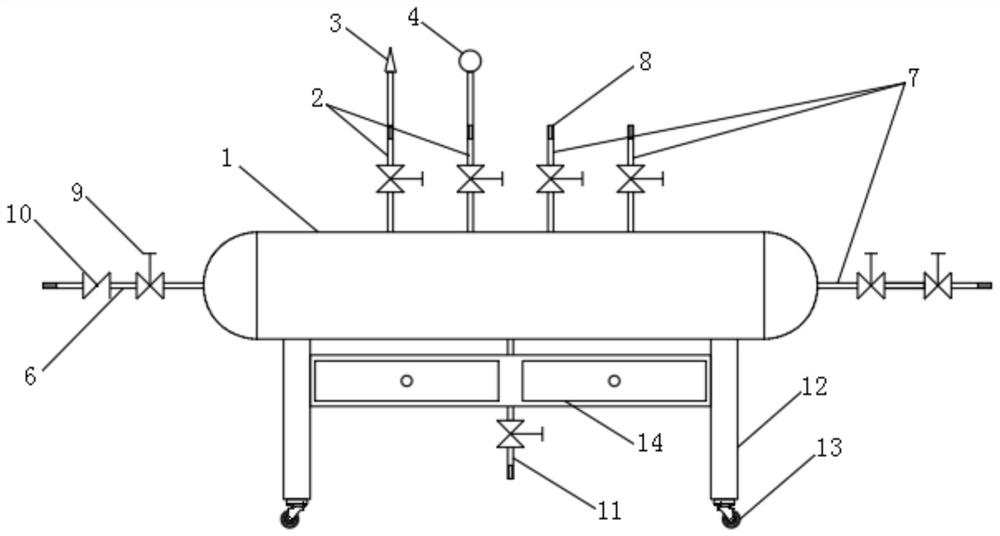

Simple buffer tank and application thereof

PendingCN113757571AAvoid accidental injuryNormal pressureHollow article cleaningPipe elementsSafety valveBuffer tank

The invention relates to a simple buffer tank which comprises a tank body, a safety valve connected with the tank body through a branch pipe, a pressure gauge and a tank cavity volume adjusting assembly installed in the tank body. The tank cavity volume adjusting assembly comprises an air inlet pipe, an air bag fixed in the middle of an inner cavity of the tank body and communicated with the air inlet pipe and an inflation and deflation mechanism connected with the air inlet pipe, and the air bag is enlarged / shrunk in the tank body under the inflation / deflation work of the inflation and deflation mechanism so as to adjust the volume of the tank body. The buffer tank is applied to a pipeline pressure testing system, an inlet pipe is connected with a pressure testing pump, and an outlet pipe is connected with a pressure testing bag. The buffer tank with the safety valve is connected between the pressure testing pump and the pressure testing bag, the pressure testing mode that the pressure testing pump and the pressure testing bag are directly connected is broken, the pipeline pressure testing system with the buffer tank can guarantee normal pressure in the system, accidental injury caused by damage of a pressure gauge is avoided, the volume of the tank body is changed through inflation and deflation of the air bag, buffering time can be changed, and the buffer tank is suitable for pipeline pressure testing with different requirements.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

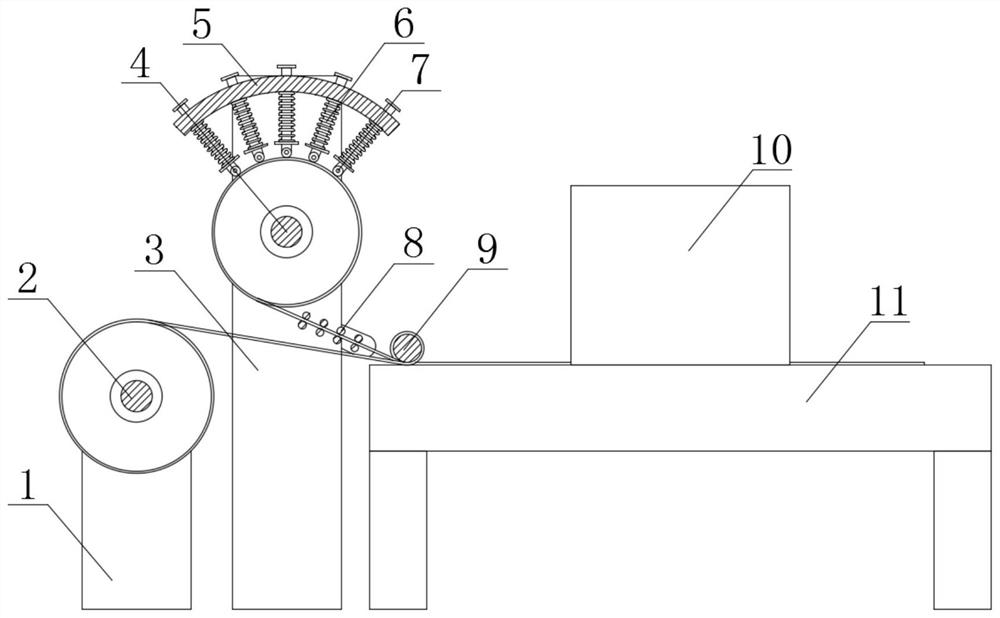

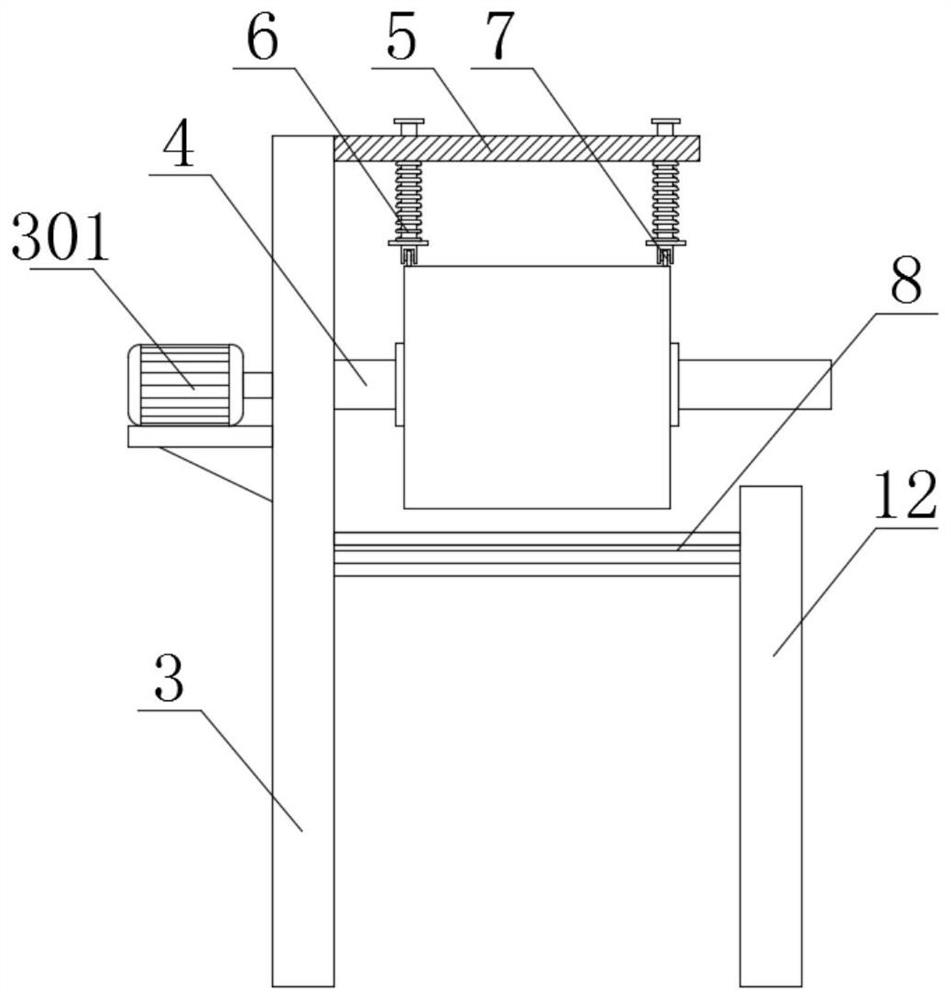

Waste material winding device for jump cutting machine

The invention discloses a waste material winding device for a jump cutting machine. The waste material winding device comprises a winding support, a waste material support, a jump cutting mechanism and a rack. The center of the top of the rack is fixedly connected with the jump cutting mechanism through a screw, and one side of the top of the rack is rotationally connected with a guide roller through a bearing. The waste material support is fixedly connected to one side of the ground at the end, close to the guide roller, of the rack with screws. Composite adhesive tape and finished products obtained after punching is completed are guided into a winding roller through the guide roller, waste materials enter a waste material roller to be wound, in the waste material winding process, the waste materials are extruded and guided out through a pressing roller. The phenomenon that the waste materials are deformed due to excessive tension in the winding process is prevented. Meanwhile, pressure is applied to the two sides of the waste materials through the pressing wheels at the bottoms of spring sleeve rods on arc-shaped supporting plates in the winding process, and normal pressure application of the pressing wheels is guaranteed through stretching and retracting of the spring sleeve rods in the process that the diameters of the waste materials are continuously increased; And it is guaranteed that the waste materials are kept unchanged in the winding process, and the waste materials can be neatly wound conveniently.

Owner:重庆安洁电子有限公司

Solar power generation based hydrogen collecting equipment for hydrogen production by water electrolysis

InactiveCN110552019ANormal pressureImprove stabilityCellsEnergy inputElectrolysisHydrogen compression

The invention discloses solar power generation based hydrogen collecting equipment for hydrogen production by water electrolysis. The hydrogen collecting equipment comprises a water electrolysis device, a hydrogen storage box, a collecting pipe, a conveying pipe, a connecting pipe, a compressor, a hydrogen storage tank and a sealing plate, wherein the hydrogen storage box is arranged on one side of the water electrolysis device, the collecting pipe is fixed on the inner wall of the hydrogen storage box, the conveying pipe is fixed at one end of the collecting pipe, one end, away from the hydrogen storage box, of the conveying pipe communicates with a hydrogen outlet end of the water electrolysis device, the connecting pipe is fixed at the top of the hydrogen storage box, the compressor isarranged at one end of the hydrogen storage box, one end, close to the compressor, of the connecting pipe communicates with a gas inlet of the compressor, the hydrogen storage tank is arranged on oneside of the compressor, an exhaust port of the compressor communicates with the gas inlet of the hydrogen storage tank, the inner wall of the hydrogen storage box is connected with the sealing plate in a sliding manner, and the middle of the sealing plate is connected with the collecting pipe in a sliding manner. The solar power generation based hydrogen collecting equipment for hydrogen production by water electrolysis can provide buffer capacity for the compressor during hydrogen compression and improve output stability of the compressor.

Owner:北京八度阳光科技有限公司

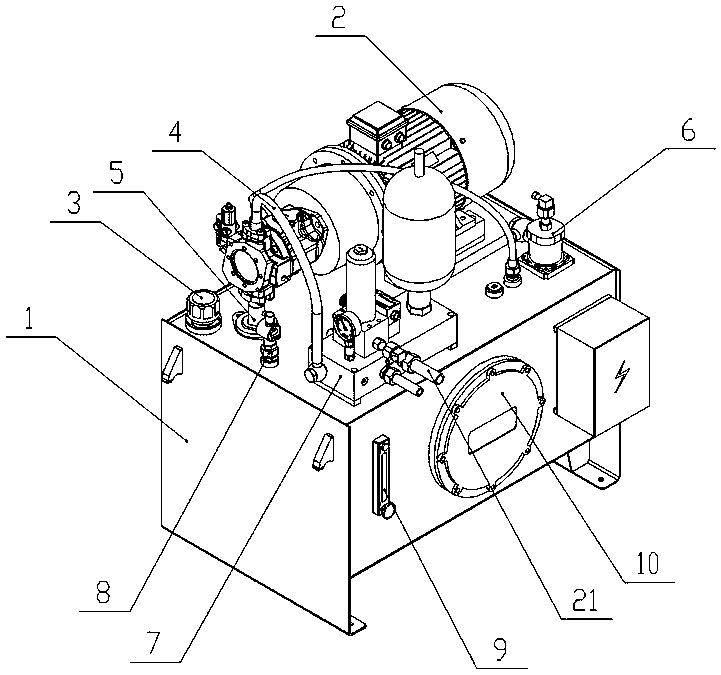

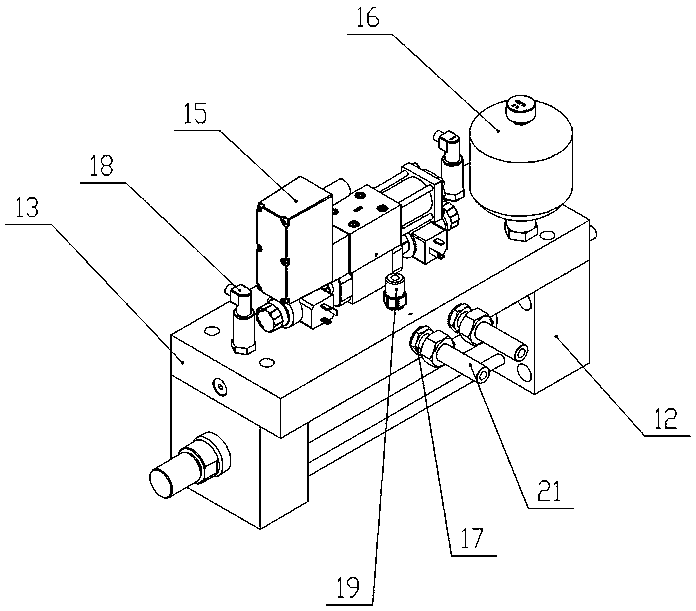

Multi-cylinder control hydraulic system for wire stripping machine

PendingCN109424594AAvoid damageGuaranteed concentricityServomotorsFluid-pressure actuator componentsLiquid temperatureAir filter

The invention discloses a multi-cylinder control hydraulic system for a wire stripping machine. The multi-cylinder control hydraulic system for the wire stripping machine comprises a servo pump groupand servo cylinders, wherein the bottom end of the servo pump group is fixedly connected with the top end of an oil tank; an oil inlet of the servo pump group is fixedly connected with the oil tank through an oil suction hard pipe; an air filter, a liquid level and liquid temperature controller and a servo valve group are separately arranged on one side of the top end of the oil tank; and an oil outlet of the servo pump group is fixedly connected with an oil inlet of the servo valve group through an oil discharging hose. According to the multi-cylinder control hydraulic system for the wire stripping machine, the three servo oil cylinders are arranged to form a delta shape, two servo oil cylinders are pushed upwards and one is pushed downwards, a workpiece is placed on a bracket, the threeservo oil cylinders are supported on the bracket together, the three servo oil cylinders are located on the same circumference, and concentricity is ensured, a displacement sensor can detect the lifting height of a hydraulic telescopic rod, a liquid level liquid thermometer can detect the oil quantity and the oil temperature of hydraulic oil in the oil tank, and a vibration proof pressure gauge measures the pressure of oil in the servo valve group through a pressure gauge joint to prevent equipment damage caused by excessive oil pressure.

Owner:WUXI FOREVER AUTOMATION TECH CO LTD

Self-cleaning vacuum homogenizing and emulsifying machine

InactiveCN110479155AWash thoroughlyAvoid scratchesRotary stirring mixersTransportation and packagingMaterial resourcesPulp and paper industry

The invention belongs to the field of emulsifying devices, and particularly relates to a self-cleaning vacuum homogenizing and emulsifying machine which comprises a stirring tank body, a stirring mechanism, a cleaning mechanism, a vertical driving device, a rotating support, a first top cover, a second top cover, a rack and a booster pump. The stirring tank body is fixed at the lower portion of the rack, a discharging port is located at the bottom of the stirring tank body, and a discharging valve is installed on the discharging port; the stirring mechanism and the cleaning mechanism are respectively fixed below the first top cover and the second top cover, the first top cover and the second top cover are symmetrically and fixedly suspended at the bottom end of the rotating support, and the stirring mechanism is positioned right above the stirring tank body in a non-working state; the rotating support is fixed at the bottom end of the vertical driving device, the upper portion of the vertical driving device is fixed to the upper portion of the rack, and the stirring device and the cleaning mechanism are externally connected with a booster pump through flexible pipes. The self-cleaning vacuum homogenizing and emulsifying machine cleans an emulsifying machine more thoroughly, enables the service life of the emulsifying machine to be prolonged, saves the manpower and material resources, and guarantees the safety of the equipment with the arrangement of a pressure control device.

Owner:云和县博丽森科技有限公司

Electric control circuit of air compressor for salt bag packing machine

ActiveCN105697349BReduce the temperatureExtend your lifePump controlPositive-displacement liquid enginesGas compressorEngineering

The invention relates to an air compressor electric control circuit for a salt bag packing machine. The air compressor electric control circuit for the salt bag packing machine comprises a plurality of air compressor circuit bodies which are sequentially connected with power leads. Each air compressor circuit body comprises an air switch QF connected with a power source and an alternating current contactor KM connected between the air switch QF and a motor M, and a safety resistor RF is connected between the alternating current contactor KM and the motor M. A time relay KT is arranged in each air compressor circuit body. A pressure switch K is arranged on each air compressor circuit body. The pressure switch K of the front air compressor circuit body is sequentially connected with the time relay KT of the back air compressor circuit body. The effect that an air compressor operates efficiently and orderly is ensured through the time relays KT and the pressure switches K which are arranged additionally.

Owner:中盐安徽润华强旺盐业有限公司

Chinese herbal medicine decocting device capable of detecting water level

A Chinese herbal medicine decocting device capable of detecting the water level comprises a supporting plate. Supporting columns are arranged on the lower portion of the supporting plate, a medicine decocting mechanism is arranged on the supporting plate, and a power strip is arranged on one side of the medicine decocting mechanism. A medicine decocting box is arranged in the medicine decocting mechanism, a folding plate is arranged at the top of the medicine decocting box, and a penetrating hole is formed in the folding plate. A water level lifting rod is arranged in the penetrating hole andpenetrates through the penetrating hole, and a pressure release valve is arranged on one side of the penetrating hole. According to the Chinese herbal medicine decocting device, heating is conducted through the medicine decocting box in the medicine decocting mechanism, the water level is detected through the water level lifting rod, the water level is controlled according to the actual water level, pressure release is conducted through the pressure release valve to ensure the normal pressure, the medicine decocting effect is improved, meanwhile, the medicine decocting speed is increased, medicine decocting safety is improved, and meanwhile, impurities are reduced through storage of a Chinese medicine box.

Owner:朱兆晖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com