Vacuum precooling storage fresh keeping method of spinach

A technology for storage and preservation of spinach, which is applied to the preservation of fruits and vegetables, preservation of fruits/vegetables through freezing/refrigeration, food preservation, etc. It can solve the problems of small size of fresh-keeping refrigerators, inconvenient use of vegetables, limited condition parameters, etc., and achieve compact structure , easy to use, and the effect of reducing the rate of decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

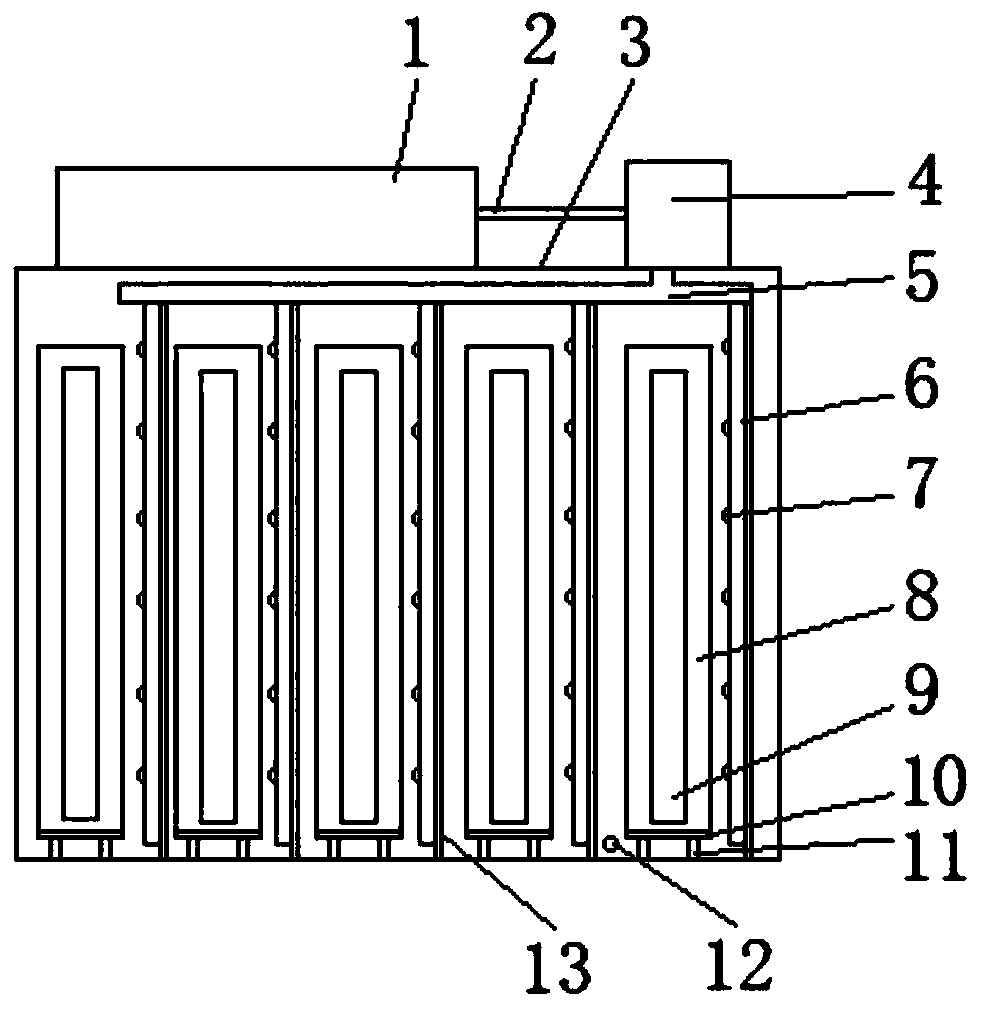

Image

Examples

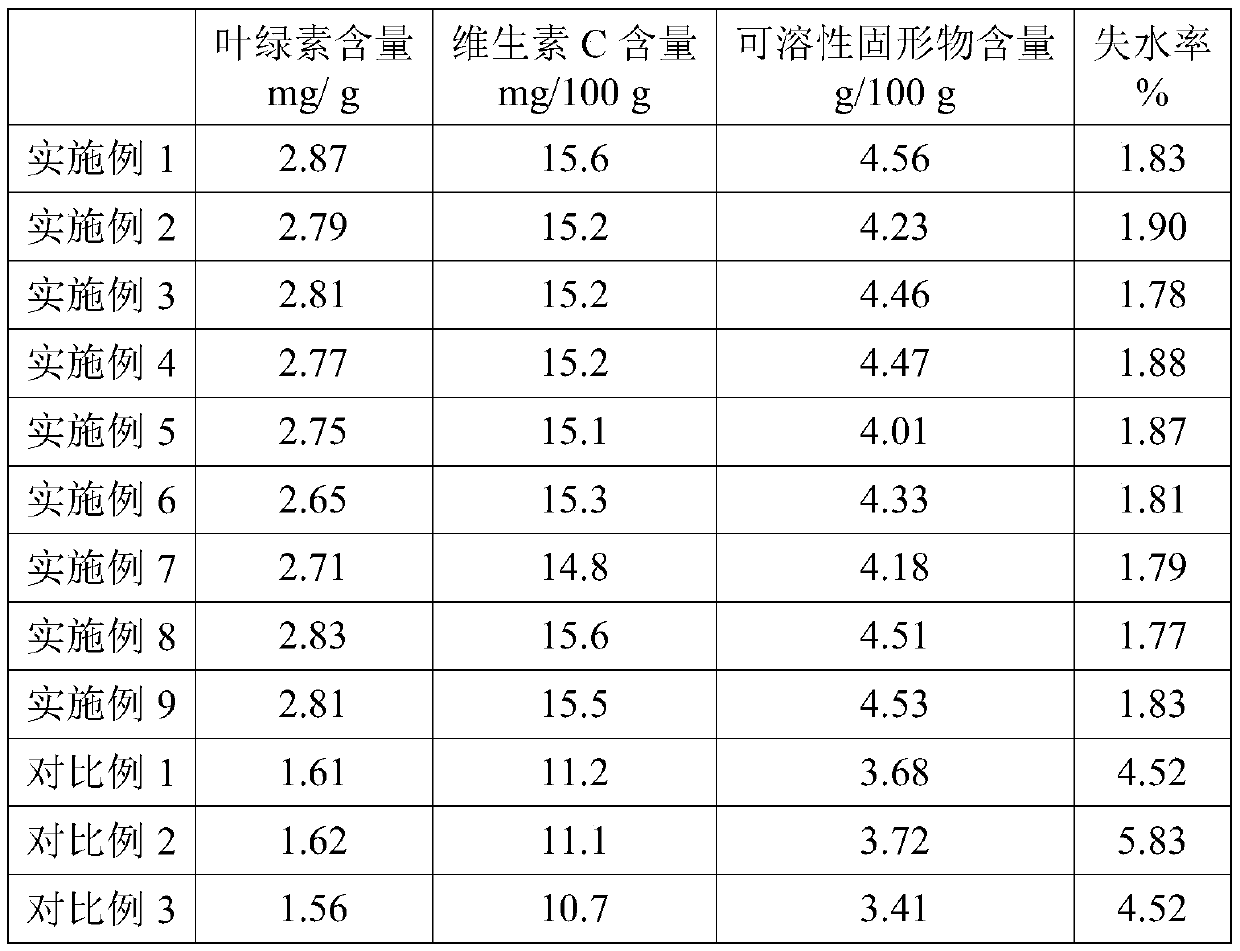

Embodiment 1

[0029] The vacuum precooling storage and fresh-keeping method of spinach, the steps are as follows:

[0030] Step 1. Pick mature fresh spinach, wash off the root soil, trim the root, keep the main root length of 3.5cm, remove the yellow and rotten leaves, ventilate and dry the water droplets on the surface of the spinach, use 0.35kg / handle, and air-dry the spinach on the surface with a rope tied up;

[0031] Step 2. Spray distilled water on the bundled spinach in step 1: Spray 20g of distilled water per 1000g of spinach, and quickly put it into the vacuum pre-cooling equipment for pre-cooling treatment until the final pre-cooling temperature of spinach is 4°C, and the pre-cooling time is 8 minutes;

[0032] Step 3. In a sealed environment at 4°C, sterilize the vacuum-precooled spinach in step 2 by UV-C irradiation and put it into a PE fresh-keeping bag. The root of the spinach faces the bag opening, and the fresh-keeping bag is exposed to UV The irradiation dose of -C is 1.5k...

Embodiment 2

[0038] The vacuum precooling storage and fresh-keeping method of spinach, the steps are as follows:

[0039] Step 1. Pick mature fresh spinach, wash off the root soil, trim the root, keep the main root length 3cm, remove the yellow and rotten leaves, ventilate and dry the water droplets on the surface of the spinach, and use 0.3kg / handle to bundle the air-dried spinach with a rope into a tie;

[0040] Step 2. Spray distilled water on the bundled spinach in step 1: Spray 20g of distilled water per 1000g of spinach, and quickly put it into the vacuum precooling equipment for precooling treatment until the final precooling temperature of spinach is 5°C, and the precooling time is 5min;

[0041] Step 3. In a sealed environment at 4°C, sterilize the vacuum-precooled spinach in step 2 by UV-C irradiation and put it into a PE fresh-keeping bag. The root of the spinach faces the bag opening, and the fresh-keeping bag is exposed to UV The irradiation dose of -C is 1.4kJ / m 2 ;

[004...

Embodiment 3

[0047] The vacuum precooling storage and fresh-keeping method of spinach, the steps are as follows:

[0048] Step 1. Pick mature fresh spinach, wash off the root soil, trim the root, keep the main root length 4cm, remove the yellow and rotten leaves, ventilate and dry the water droplets on the surface of the spinach, use 0.4kg / handle, and bundle the air-dried spinach with a rope into a tie;

[0049] Step 2. Spray distilled water on the bundled spinach in step 1: Spray 20g of distilled water per 1000g of spinach, and quickly put it into the vacuum precooling equipment for precooling treatment until the final precooling temperature of spinach is 3°C, and the precooling time is 10min;

[0050] Step 3. In a sealed environment at 4°C, sterilize the vacuum-precooled spinach in step 2 by UV-C irradiation and put it into a PE fresh-keeping bag. The root of the spinach faces the bag opening, and the fresh-keeping bag is exposed to UV The irradiation dose of -C is 1.6kJ / m 2 ;

[0051...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com