Culture kettle with temperature control structure for bio-based material production

A bio-based and kettle body technology, which is applied in chemical/physical processes, dissolution, mixers, etc., can solve problems affecting the quality of bio-based material preparation, insufficient mixing and stirring of culture kettles, and a single stirring shaft to achieve convenient transfer and transportation , Improve the effect of fixing and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

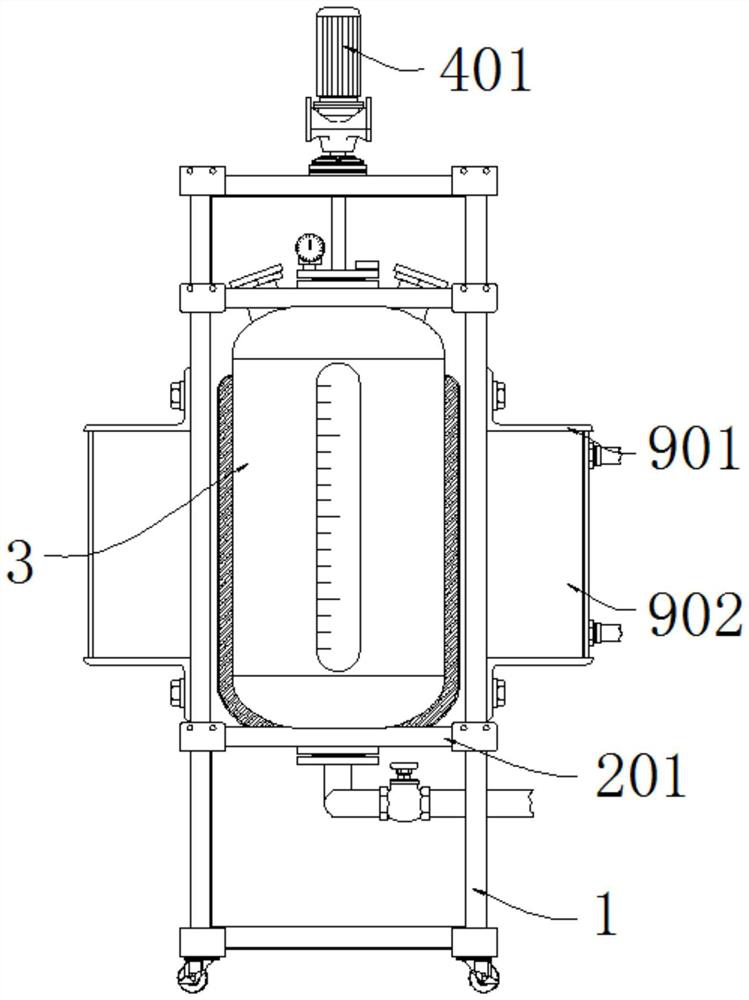

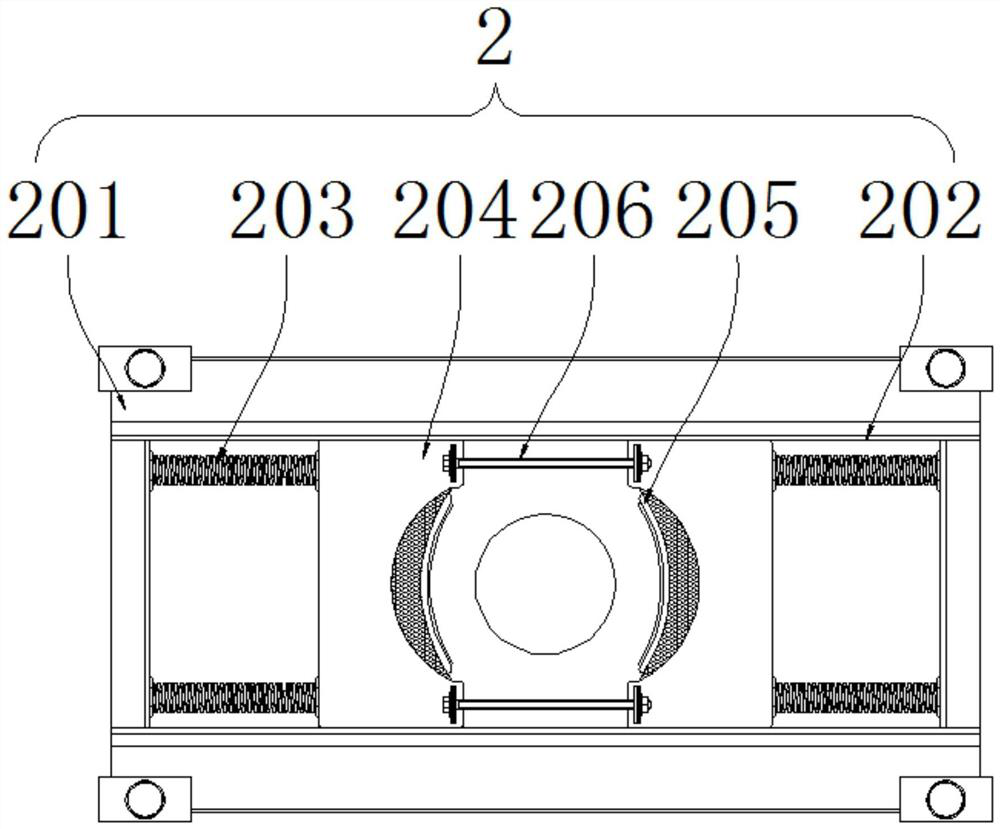

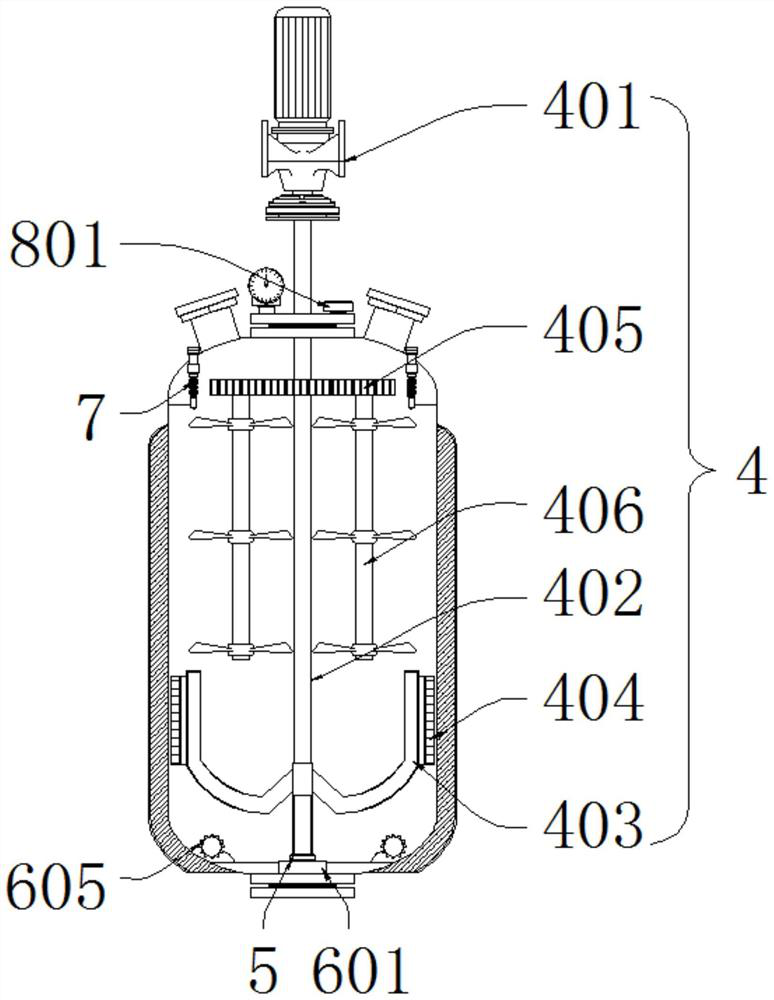

[0031] see Figure 1-9, the present invention provides a technical solution: a culture kettle with a temperature control structure for the production of bio-based materials, including an external frame 1 and an anti-sedimentation component 6, an auxiliary component 2 is installed inside the external frame 1, and the auxiliary component 2 A kettle body 3 is arranged inside, and a stirring assembly 4 is installed inside the kettle body 3, and the stirring assembly 4 includes a servo motor 401, a stirring shaft 402, a stirring blade 403, a scraper 404, a gear set 405 and an auxiliary shaft 406, and the servo motor 401 The output end is connected with a stirring shaft 402, the bottom of the stirring shaft 402 is provided with a stirring blade 403, and the outer wall of the stirring blade 403 is connected with a scraper 404, the outside of the stirring shaft 402 is provided with a gear set 405, and the middle part of the gear set 405 is pierced with an auxiliary shaft 406 , the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com