A method of producing particle reinforced aluminum-base compound material continuously by using extrusion-upsetting and device thereof

A particle-reinforced aluminum and composite material technology, which is applied in metal extrusion control equipment, metal containers to be extruded, metal extrusion, etc., can solve the problems of unrealized extrusion and upsetting continuous composite material preparation technology, and reach the applicable level wide, saving energy, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

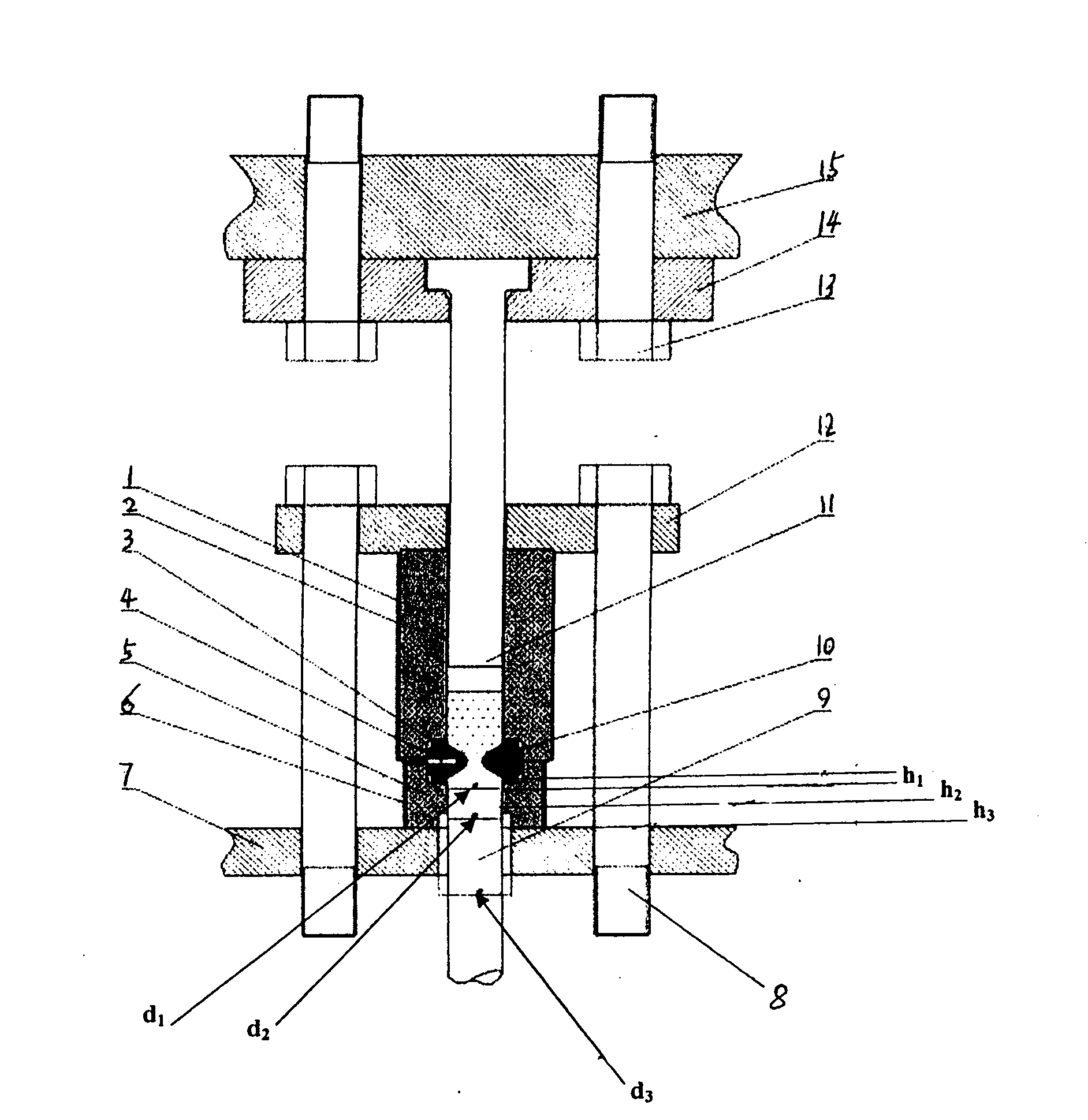

[0055] (10) Preparation of extruded and upsetting continuous composite materials.

[0056] The blank is produced by mechanically mixing the reinforcing powder material and aluminum alloy powder, including the following steps:

[0057] a. Put the aluminum alloy powder with a particle size of 40-150 μm and 5% to 25% of the reinforcement phase with a particle size of 25-150 μm into a mixer and mechanically mix until completely uniform;

[0058] b. Do not add any solvent when dry mixing, add 2vol% absolute alcohol and 1wt% polyethylene glycol when wet mixing;

[0059] c. Extrude the mixed powder into a billet with the same nominal diameter as the extrusion barrel.

[0060] The method of the present invention further comprises the following steps:

[0061] (11) Pack the extruded composite material prefabricated compact into the upper extrusion barrel (1), and extrude the billet with the upper extrusion rod;

[0062] (12) After 80% of the billet is squeezed into the lower extrusi...

Embodiment 1

[0068] Example 1 10% SiC p / Al composite material

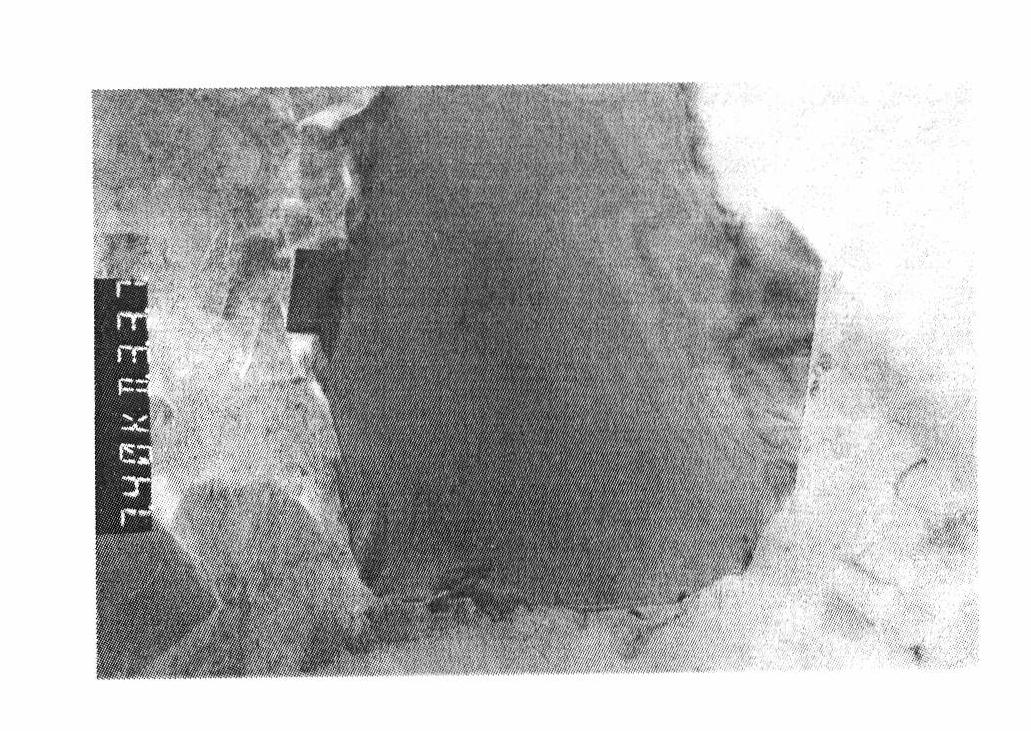

[0069] SiC calcined at 800°C p Fully mix with Al powder for 20 minutes; then, put the powder into the billet extrusion barrel, put it on the platform of the extruder, apply 4MPa pressure, and keep the pressure for 10 minutes (pressed into a billet with a specification of D A mm (extrusion barrel diameter) × 55mm) to make a billet; put the billet into extrusion barrel A for extrusion. Following the process discussed above, 10% SiC p The tensile strength of the / Al composite material is more than 120MPa, and the elongation reaches 26%. Compared with pure aluminum, the tensile strength is nearly doubled, but the elongation does not decrease significantly. The reinforcement is well bonded to the matrix, such as figure 2 shown.

Embodiment 2

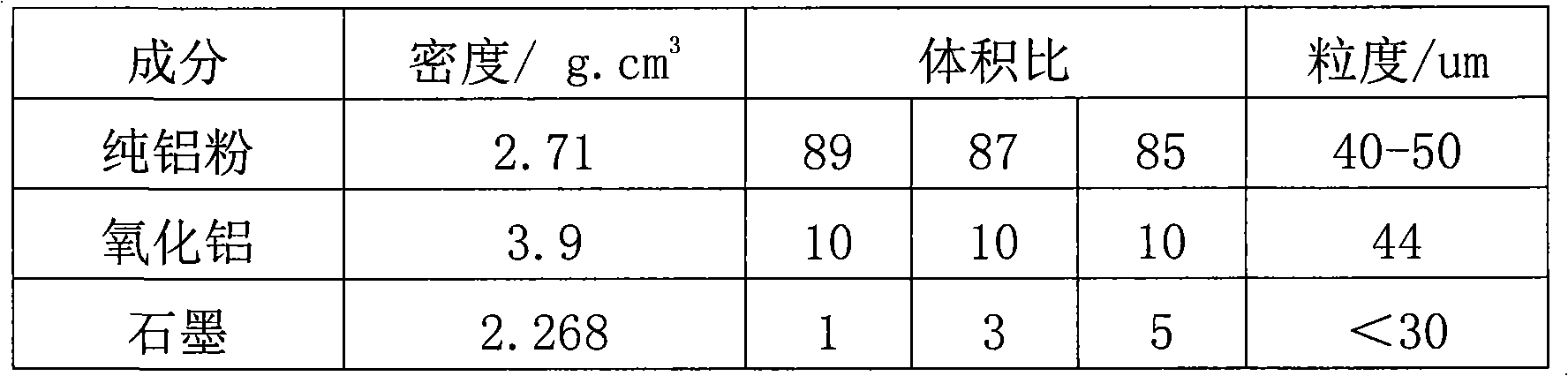

[0070] Example 2 5vol.% Graphite-10vol.% Al 2 o 3 / Al composite material

[0071] Surfactant polyethylene glycol PEG2000

[0072] Wet mixing medium: absolute ethanol

[0073] For mixing, first put pure aluminum powder, then add 1wt% absolute ethanol, then add graphite powder, stir with a glass rod while adding, then add 0.5wt% polyethylene glycol PEG2000, and finally add Al 2 o 3 powder, stirred with a glass rod for 5 min. Put the stirred wet powder into the prepared clean PVC bottle, put it on the self-made mixer for mixing, and the speed of the mixer is 65r / min. The mixing time is 4h~12h respectively. Surfactant and absolute ethanol act as grinding medium and grinding aid at the same time, which not only prevents particles from re-aggregating and growing, but also promotes the diffusion of crushing cracks, accelerates grinding, and plays the role of grinding fine particles. At the same time, the addition of surfactant makes the agglomerated particles loose and dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com