Die and method for forming composite material I-shaped beam

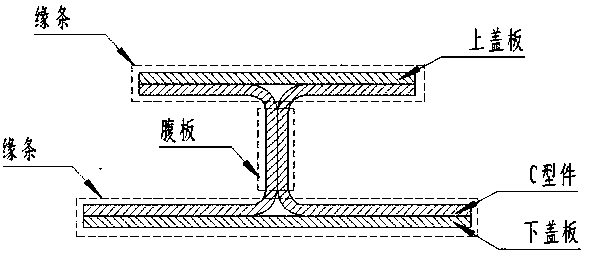

A technology of composite materials and forming molds, which is applied in household appliances, other household appliances, household components, etc., can solve the problems of difficult to meet the requirements of appearance quality, uneven thickness of I-shaped structural beam webs, and edge strips, and achieve appearance quality Excellent, reduced processing cost, uniform thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

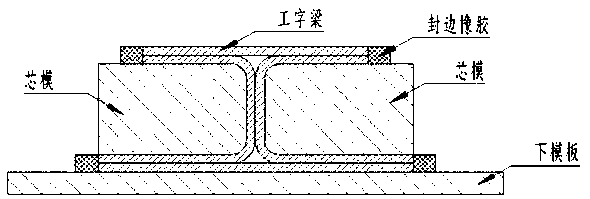

Method used

Image

Examples

Embodiment 2

[0032] A method for forming a composite I-beam is characterized in that it comprises the steps of:

[0033] Step 1: First, complete the laying and compaction of the left and right C-shaped parts of the I-beam, the upper and lower cover plates on the upper mold body 1 of the forming mold, the lower mold body 2 of the forming mold, and the pressure plate 5;

[0034] Step 2: After the lay-up and compaction of the prepreg blanks of each part of the I-beam are completed, the blanks are not removed from the mold body, and the upper mold body 1 of the forming mold, the lower mold body 2 of the forming mold, and the pressing plate are directly placed 5 are assembled together by the positioning support structure and the movable pin 6,

[0035] Step 3: Complete vacuum bagging of the assembly obtained in step 2 in the tooling vacuum bagging area;

[0036] Step 4: Transfer the packaged system to an autoclave for curing.

Embodiment 1

[0038] A method for forming a composite I-beam is characterized in that it comprises the steps of:

[0039] Step 1: First, complete the laying and compaction of the left and right C-shaped parts of the I-beam, the upper and lower cover plates on the upper mold body 1 of the forming mold, the lower mold body 2 of the forming mold, and the pressure plate 5;

[0040] Step 2: After the lay-up and compaction of the prepreg blanks of each part of the I-beam are completed, the blanks are not removed from the mold body, and the upper mold body 1 of the forming mold, the lower mold body 2 of the forming mold, and the pressing plate are directly placed 5 are assembled together by the positioning support structure and the movable pin 6,

[0041] Step 3: Complete vacuum bagging of the assembly obtained in step 2 in the tooling vacuum bagging area;

[0042] Step 4: Transfer the packaged system to an autoclave for curing.

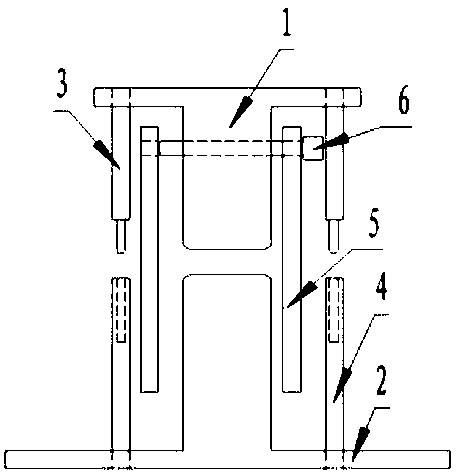

[0043] A mold for forming a composite I-beam includes a forming d...

Embodiment 3

[0045] A mold for forming a composite I-beam includes a forming die upper die body 1 and a forming die lower die body 2, characterized in that: the forming die upper die body 1 and the forming die lower die body 2 are in an H-shaped vertical In combination, a positioning support structure is set between the upper mold body 1 of the forming mold and the lower mold body 2 of the forming mold. The upper mold body 1 of the forming mold is provided with penetrating pin holes, and pressure plates 5 are provided on both sides.

[0046] The pressing plate 5 is located on both sides of the forming die, and the pressing plate 5 is provided with pin holes, and is connected with the upper mold body 1 of the forming die by the movable pin 6, and the pressing plate 5 can be displaced in the horizontal direction after being connected by the movable pin 6.

[0047] The positioning support rod 3 and the positioning support pile 4 are arranged diagonally between the upper mold body 1 of the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com