Electric control circuit of air compressor for salt bag packing machine

A technology of electrical control and air compressor, which is applied in pump control, machine/engine, mechanical equipment, etc. It can solve the problems of long running time, large voltage fluctuation, and large instantaneous starting current, etc., and achieves the extension of machine head life and voltage fluctuation. Small, the effect of small starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

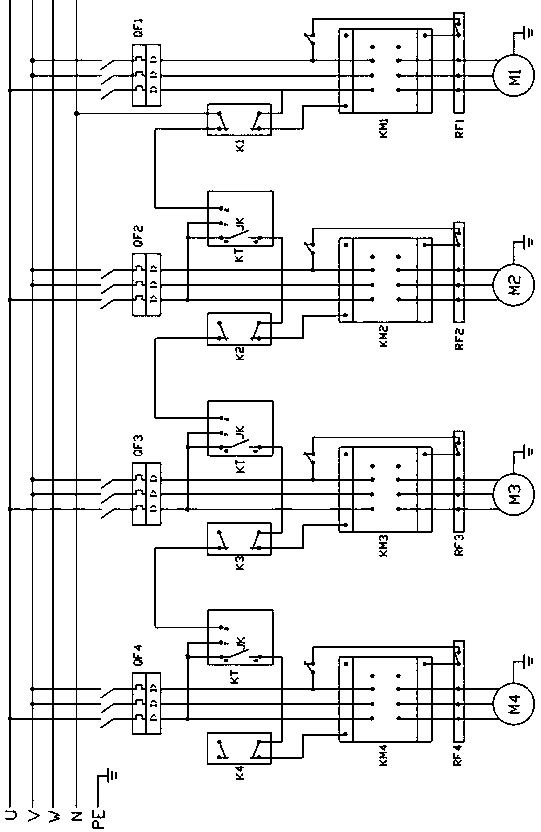

[0010] Here is an explanation of the concept of pre-sequence air compressors and post-sequence air compressors. Several air compressors arranged in sequence are started sequentially. When several air compressors are working normally, the one that starts first is defined as the pre-sequence air compressor. The definition of post-start is the post-sequence air compressor. refer to figure 1 , the air compressor starts from right to left M1, M2, M3, M4 in sequence.

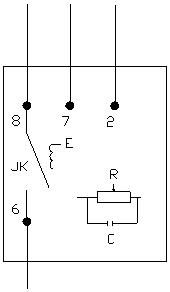

[0011] An electrical control circuit for an air compressor, including several air compressor circuits sequentially connected to a power supply lead-in line, each air compressor circuit includes an air switch QF connected to the power supply, and an air switch QF connected between the air switch QF and a motor M The AC contactor KM, the insurance resistor RF is connected between the AC contactor KM and the motor M, the time relay KT is set between the circuits of each air compressor, the pressure switch K is set for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com