Power constant system capable of automatically adjusting electrode position and working method of power constant system

A technology with constant power and automatic adjustment. It is applied in electric heating devices, electrical components, and energy efficiency improvement. It can solve the problems of long smelting time, increased electrode consumption, and increased power consumption, so as to improve smelting quality, efficiency, and safety factor. High and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

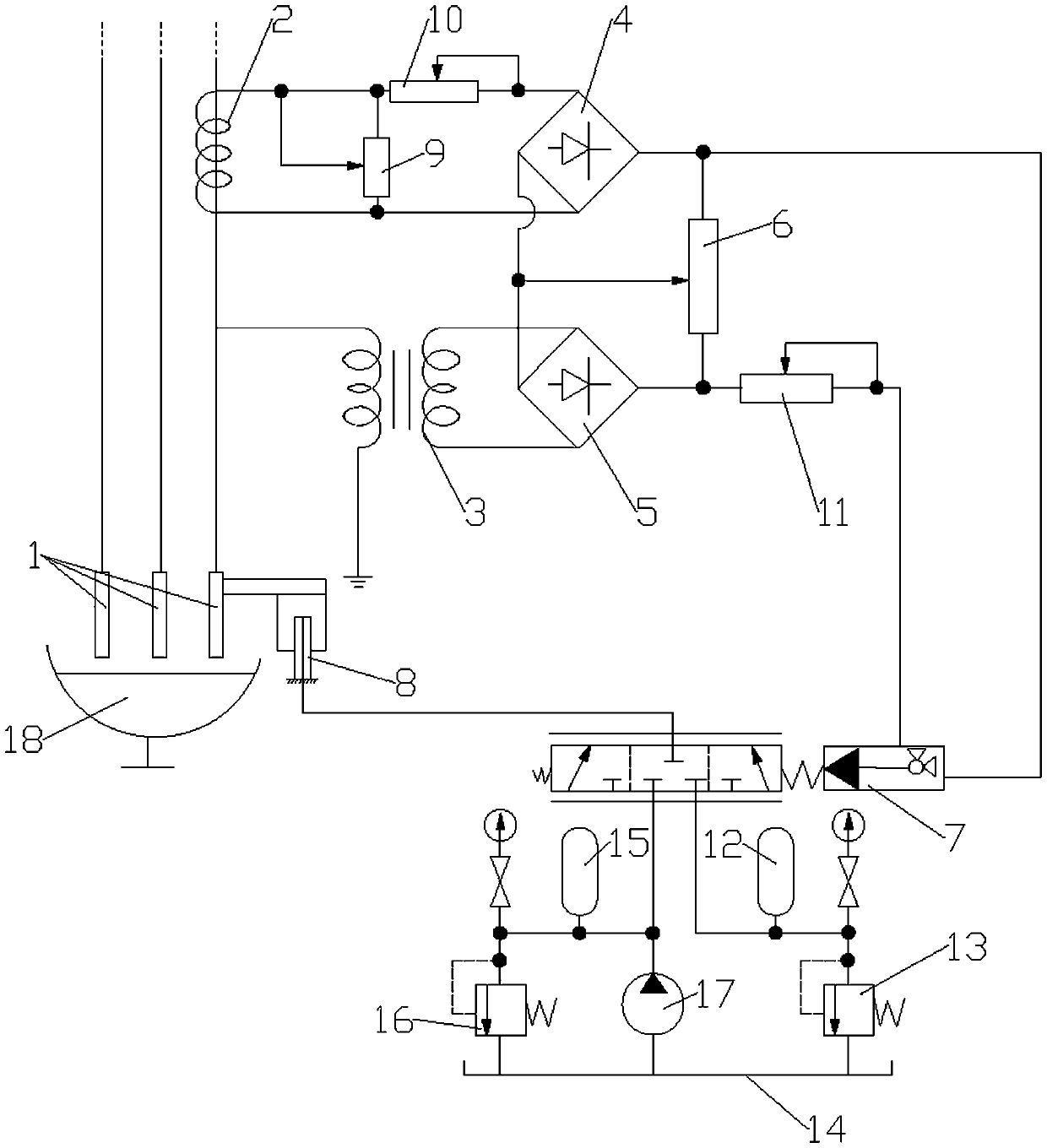

[0023] like figure 1 As shown, a power constant system that can automatically adjust the position of the electrode includes a current transformer 2 for detecting the current of the electrode 1, an isolation transformer 3 for detecting the voltage of the electrode 1, a first rectifier 4, a second rectifier 5, and a second rectifier. A sliding rheostat 6, including a second sliding rheostat 9, a third sliding rheostat 10, a fourth sliding rheostat 11, a three-position three-way servo valve 7, a plunger cylinder 8, an oil return circuit and an oil injection circuit, and a current transfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com