Distiller and distillation device

A technology of a distillation device and a distiller, which is applied in the field of winemaking, can solve problems such as uneven heating, and achieve the effects of uniform heating, preventing sticking to the pot and improving wine quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

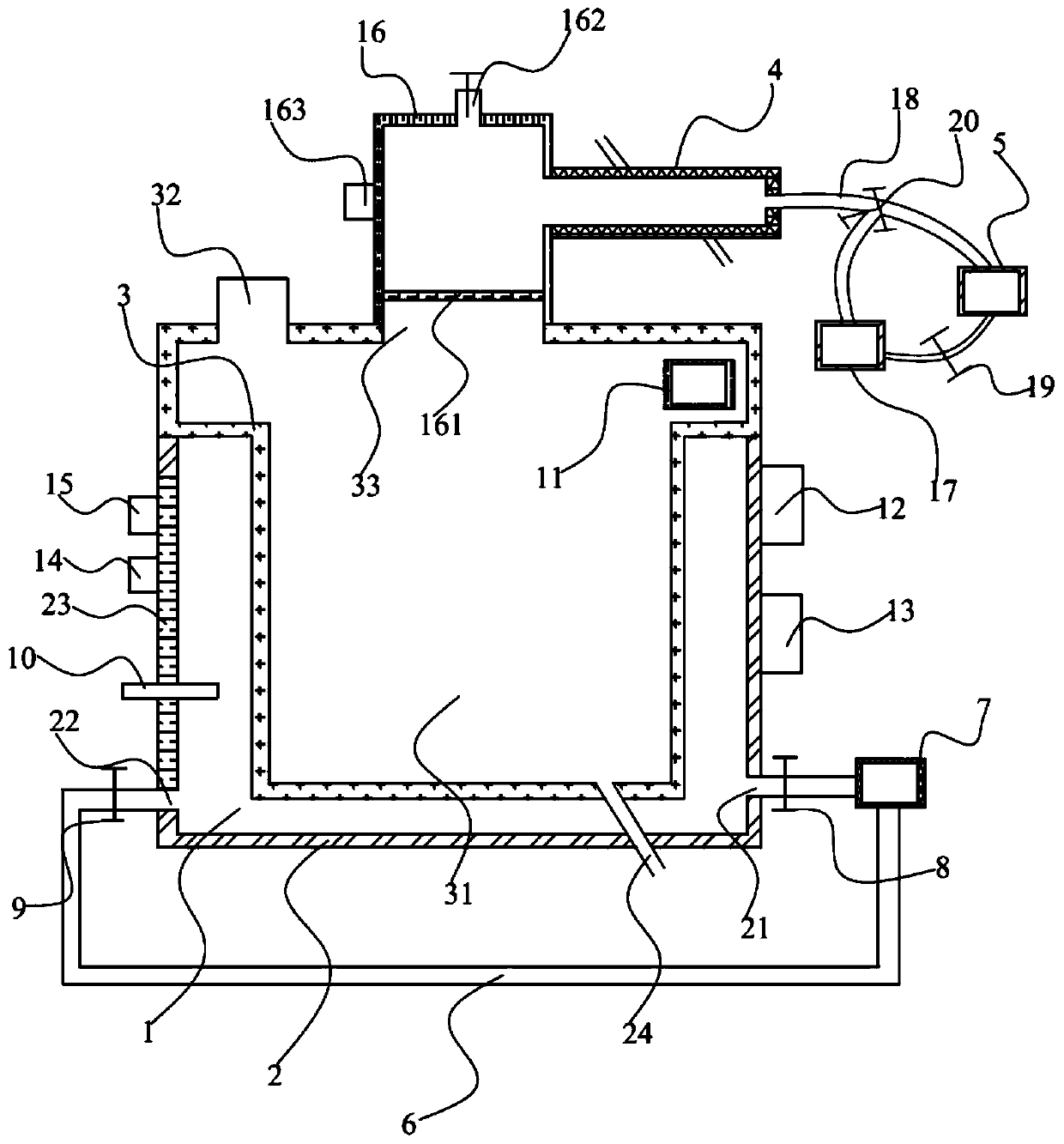

[0068] Such as figure 1 A specific embodiment of the distiller shown includes an inner cylinder 3, inside which is formed a housing chamber 31 suitable for holding fermented grains, and the inner cylinder 3 is provided with a feed port 32 and a discharge port communicated with the housing chamber 31 33.

[0069] The outer cylinder 2 is provided with a heat medium inlet 21, the inner cylinder 3 is arranged in the outer cylinder 2, a flow chamber 1 is formed between the inner cylinder 3 and the outer cylinder 2, and the flow chamber 1 is covered outside the peripheral wall and the bottom wall of the inner cylinder 3 The heat medium inlet 21 communicates with the flow chamber 1 and a heat source suitable for supplying heat medium, and the fluid heat medium enters the flow chamber 1 from the heat medium inlet 21, so that the wine grains in the inner cylinder 3 are heated and evaporated into wine vapor.

[0070] The inner cylinder 3 includes a cylinder body 41 and an openable and ...

Embodiment 2

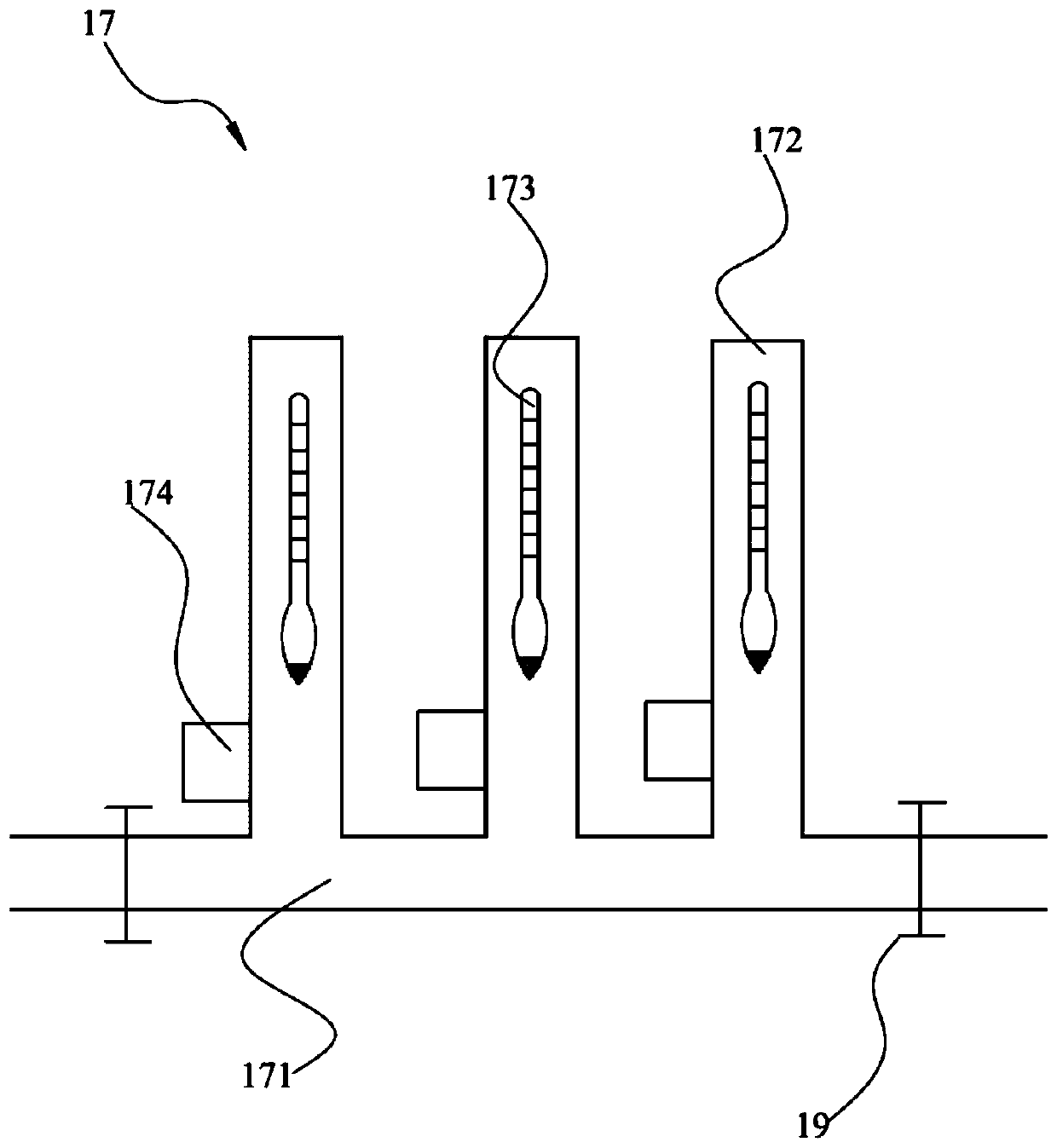

[0089] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a distillation device, comprising:

[0090] The distiller of embodiment one;

[0091] Condenser 4 communicates with the discharge port 33 of the distiller and is used to convert wine vapor into wine liquid;

[0092] The liquid reservoir 5 communicates with the outlet of the condenser 4 and is used to collect the wine liquid.

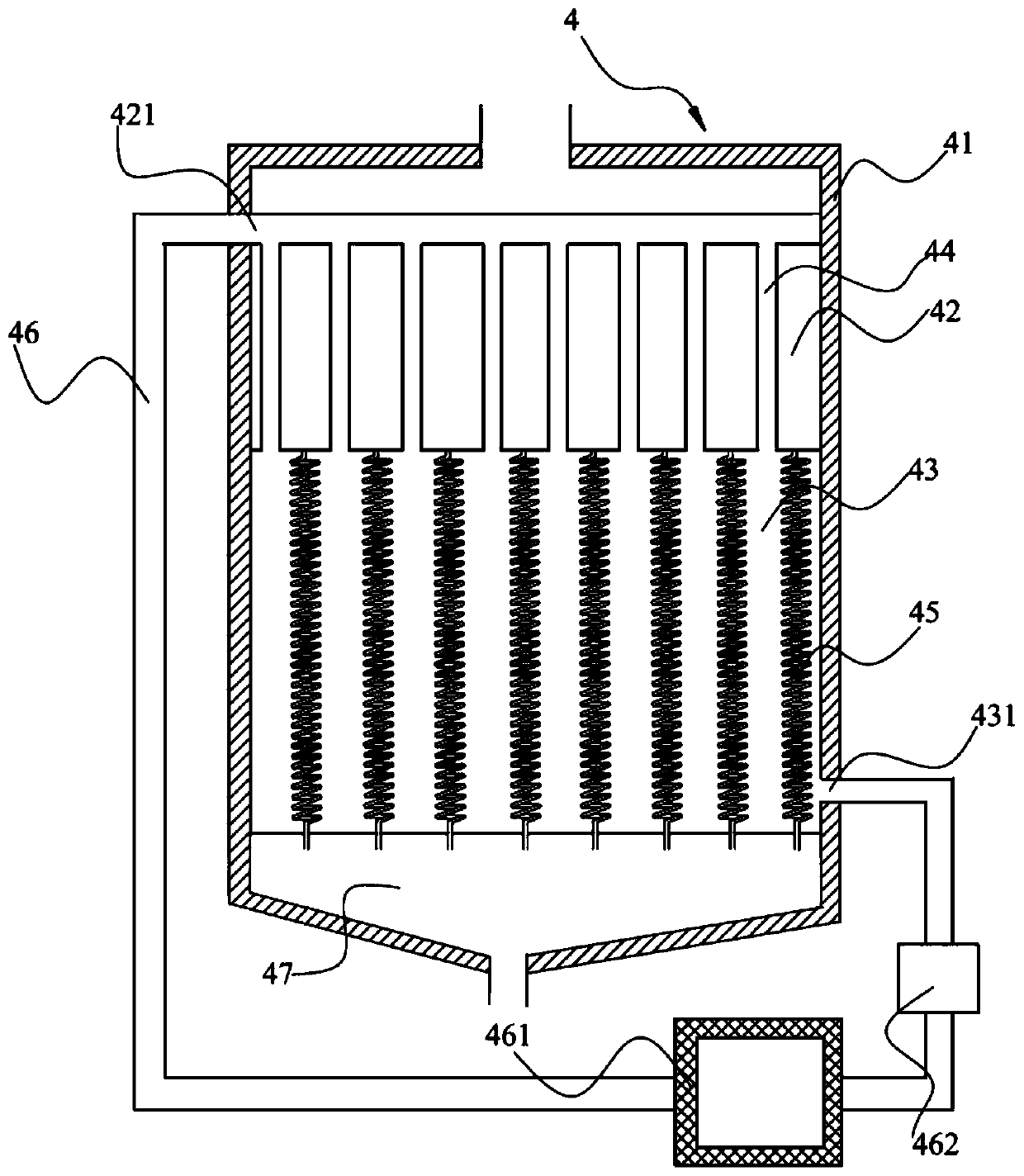

[0093] Such as figure 2 As shown, the condenser 4 includes a body 41, the body 41 is provided with a cooling inlet 431 and a cooling outlet 421, and the body 41 includes a first cooling chamber 42 and a second cooling chamber 43 separately arranged; the first cooling chamber 42 and the discharge port 33 connected, the first cooling chamber 42 is provided with a plurality of first pipes 44 at intervals, and the two ends of the first pipe 44 communicate with the cooling outlet 421 and the second cooling chamber 43 respectively; the second cooling chamber 43 communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com