Ore blending system and method in slurry pipeline conveying system

A technology of ore blending and mineral blending, which is applied in the field of mineral blending systems of different grades of minerals, can solve the problems of increasing production costs, large space required, pollution, etc., and achieve the effects of reducing labor costs, realizing economy, reducing waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

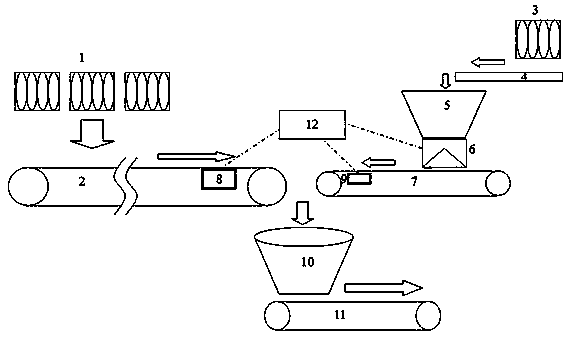

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

[0027] Preferred embodiments of the present invention are as attached figure 1 As shown, this is a preferred embodiment for the proportioning of two minerals, but the technical solution of the present invention can be applied to the equipment of multiple minerals at the same time. The technical solution of the present invention will be described below through this preferred embodiment of the present invention principle. as attached figure 1As shown, this preferred ore blending system as a whole includes a first conveyor belt 2, a fourth conveyor belt 4, a buffer bin 5, a disc feeder 6, a second conveyor belt 7, a first metering device 8, a second The metering device 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com